29

13 - STANDARD MAINTENANCE

Air conditioning equipment must be maintained by professional

technicians, whilst routine checks can be carried out locally by

specialised technicians. See the standard EN 378-4.

Simple preventive maintenance will allow you to get the best

performance from your HVAC unit:

-

improved cooling performance

-

reduced power consumption

-

prevention of accidental component failure

-

prevention of major time-consuming and costly interventions

-

protection of the environment

There are five maintenance levels for HVAC units, as defined by

the AFNOR X60-010 standard.

13.1 - Level 1 maintenance

See note below.

Simple procedure can be carried out by the user:

-

Air heat exchanger (condenser) cleaning - see chapter

“Condenser coil - level 1”

-

Check for removed protection devices, and badly closed

doors/covers

-

Check the unit alarm report when the unit does not work (see

report in the 19PV Touch'Pilot Control instruction manual ).

General visual inspection for any signs of deterioration.

13.2 - Level 2 maintenance

See note below.

This level requires specific know-how in the electrical, hydraulic

and mechanical fields. It is possible that these skills are available

locally: existence of a maintenance service, industrial site,

specialised subcontractor.

In these cases, the following maintenance operations are

recommended.

Carry out all level 1 operations, then:

-

At least once a year tighten the power circuit electrical

connections (see tightening torques table).

-

Check and re-tighten all control/command connections, if

required (see tightening torques table).

-

Check the differential switches for correct operation every 6

months.

-

Remove the dust and clean the interior of the control boxes,

if required. Check the filter condition.

-

Check the presence and the condition of the electrical

protection devices.

-

Replace the fuses every 3 years or every 15000 hours (age-

hardening).

-

Replace the control box cooling fans (if used) every five years.

-

Check the water connections.

-

Purge the water circuit (see chapter 7 “Water connections”).

-

Clean the water filter (see chapter 7 “Water connections”).

-

Check the unit operating parameters and compare them with

previous values.

-

Replace compressor capacitors every 10 years (if energized)

or 5 years (if de-energized).

-

Replace compressor soft start fan every 5 years.

-

Keep and maintain a maintenance sheet, attached to each

HVAC unit.

All these operations require strict observation of adequate safety

measures: individual protection garments, compliance with all

industry regulations, compliance with applicable local regulations

and using common sense.

13.3 - Level 3 (or higher) maintenance

See note below.

The maintenance at this level requires specific skills/approval/

tools and know-how and only the manufacturer, his representative

or authorised agent are permitted to carry out these operations.

These maintenance operations concern for example:

-

A major component replacement (compressor, evaporator)

-

Any intervention on the refrigerant circuit (handling refrigerant)

-

Changing of parameters set at the factory (application

change)

-

Removal or dismantling of the HVAC unit

-

Any intervention due to a missed established maintenance

operation

-

Any intervention covered by the warranty

NOTE: Any deviation or non-observation of these maintenance

criteria will render the guarantee conditions for the HVAC unit

nul and void, and the manufacturer, will no longer be held

responsible.

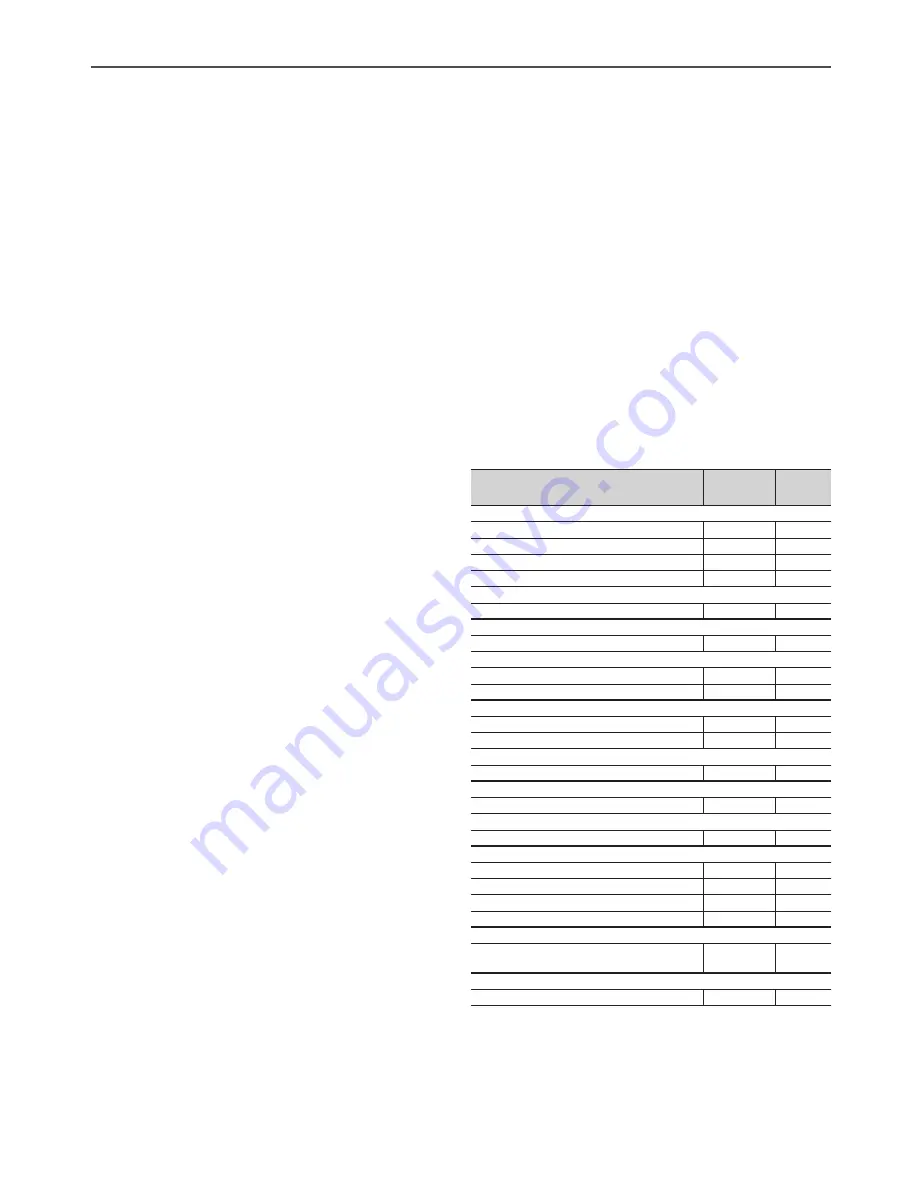

13.4 - Tightening of the electrical connections

13.4.1 - Tightening torques for the main electrical

connections

Component

Designation

in the unit

value

(N·m)

Screw on bus bar and PE, customer connection

M6

L1/L2/L3

9,6

M8

L1/L2/L3

24

M10

L1/L2/L3

49

M12

L1/L2/L3

79,4

Screw on Main supply disconnect switch

QS10*

28

Screw on Control supply disconnect switch

QS10*A

1,7

Screw on Line reactor

Line reactor for TT300 - M8

Z*

24

Line reactor for TT350 - M10

Z*

49

Screw on EMC Filter

PE

ZC*

16 (+/- 1)

Phases

ZC*

15

Screw on Fast acting fuse connection

FU*

38

Screw on TT300 bar connection

L1/L2/L3

25

Screw on PE panels

M8

PE

24

Screw on Compressor connection

TT300 - Cap

L1/L2/L3

31

TT300 - M8

PE

21,7

TT350 - M10

L1/L2/L3

21,7

TT350 - M8

PE

21,7

Control disconnect switch connection

Upstream and downstream screws at terminals

QF10* &

QM10**

2

Power supply 24VDC unit

Upstream and downstream screws at terminals

VC*

0,5

Summary of Contents for 19PV550

Page 33: ...33...