MN99102 042015

– 6 –

Model 99FRD, 102CRD & EZ-66 Oil Burners — Instruction Manual

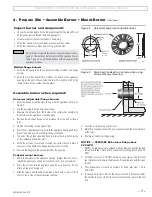

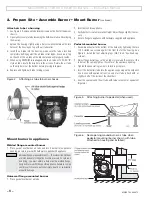

Figure 1 99FRD, EZ-66 and 102CRD Minimum combustion chamber dimensions (all dimensions in inches)

2. Prepare Site • Assemble Burner • Mount Burner

(continued)

Chamber configurations

A Chamber with water-backed floor and target wall, with refractory linings on

floor and target wall.

B Chamber with water-backed floor and target wall, with refractory lining on

target wall only.

C Chamber with water-backed floor and target wall, without refractory linings.

D Refractory chamber, no water-backed surfaces (dry base design).

E Chamber with refractory floor and water-backed target wall (

without

target

refractory lining).

F Chamber with refractory floor and water-backed target wall (

with

target refrac-

tory lining).

Notes for dimension table

1 Some tested appliances operate well with dimensions other than shown

below.

2. Generally, applications should be acceptable with dimensions larger than

listed.

3. Horizontal cylinder chambers should have a diameter at least as larger as the

minimum width listed. For steel cylinder chambers, increase this dimension

by from 1 to 4 inches.

4. Wing walls are not recommended. Corbels can be beneficial to heat distribution

in some applications.

5. DV is the minimum diameter for vertical cylindrical chambers (refractory or

refractory-lined chambers only).

Firing

rate

GPH

L

D

L

T

L

W

W

DV

C

D

C

W

H

F

Lined

Target

liner

Unlined Note 3

Note 5

Lined

Unlined

99FRD/EZ-66

0.50

7

Line floor and

target wall or

use refractory

chamber

6

7

3

NR

8

NR

0.65

7.5

7

7.5

3.5

9

0.75

8

7

8

3.5

9

0.85

10-11

12

7

8.5

3.5

4

9

5

1.00

10

11-12

13

8

9

4

4.5

10

6

1.10

11

12-13

14

8

9.5

4

4.5

10

6

1.25

1.35

1.50

1.65

1.75

2.00

2.25

2.50

2.75

3.00

102CRD

with 2

⁵⁄₈

" air cone

14

14

17

15

13

6.5

6.5

15

8

15

15

18.5

15

13.5

6.5

6.5

15

8

16

16

19.5

15.5

14.0

6.5

6.5

15.5

8

17.5

17.5

21

15.5

15.5

6.5

6.5

15.5

8

18.5

18.5

22.5

15.5

16.5

7

7

15.5

8.5

20

20

24

16

17.5

7

7

16

8.5

21

21

25

16

18.5

7

7

16

8.5

with 3" air cone

25

25

29

12

23

5

5

12

6.5

26

26

30

13

24

5.5

5.5

13

7

27

27

31

13.5

24

6

6

13.5

7.5

28

28

32.5

14

25

6

6

14

7.5

4.00

29

29

34

14.5

26

7

7

14.5

8.5

4.25

30

30

35

15.5

27

7

7

15.5

8.5

4.50

31

31

36

17

28

7.5

7.5

17

9