MN99102 042015

– 7 –

Model 99FRD, 102CRD & EZ-66 Oil Burners — Instruction Manual

Inspect burner and components

• Check the air tube length. Verify the usable length of the tube UTL will

be long enough (see “Mount burner in appliance”).

• Visually inspect all burner components and wiring.

• Verify that wiring is intact and leads are securely connected.

• Verify that all burner components are in good condition.

Do not install or operate the burner if any component is dam-

aged or if burner does not comply with the specifications of

Table 1, page 3, and other guidelines of this manual and the

appliance manual.

Welded-flange burners

1. Verify the bolt pattern on the appliance chamber matches the flange

pattern.

2. Verify the insertion depth (UTL) matches the depth of the appliance

opening (so the end of the air tube is flush with, or slightly short of, the

inside surface of the combustion chamber).

Assemble burner (when required)

Universal (adjustable) flange burners

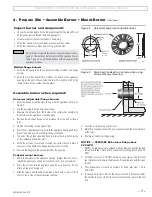

1. Verify the flange mounting slots line up with the appliance bolts. See

Figure 2.

2. Slip the adjustable flange onto the air tube.

3. Measure the distance from the inside of the combustion chamber to

the outside of the appliance mounting plate.

4. Position the universal flange at this distance from the end of the air

tube.

5. Tighten the locking screws finger tight.

6. Insert the air tube/flange assembly into the appliance opening and level

the air tube with a spirit level. Adjust flange if needed.

7. The end of the air tube should be flush, or almost flush, with the inside

of the combustion chamber wall.

8. Verify the air tube is level and inserted the correct depth. Adjust if

necessary. Then tighten the flange locking screws securely.

9. Remove the flange/air tube assembly from the opening.

Pedestal mount burners

1. Check the diameter of the appliance opening. If larger than 4½ inches,

rebuild the opening so the open is reduced to 4½ inches maximum.

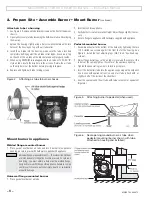

2. Insert the air tube into the appliance opening as in Figure 3. Do not

attach air tube to housing yet.

3. Slide the tube in until the end of the tube is flush with, or up to ¼ inch

short of, the inside of the combustion chamber.

Figure 2 Universal flange mounting dimensions

Figure 3 Mark insertion depth on air tube when using

universal flange mounting

2. Prepare Site • Assemble Burner • Mount Burner

(continued)

4. Level the air tube using a spirit level.

5. Mark the air tube position with a pen or pencil around the circumference

of the tube.

6. Remove air tube from the opening.

NOTICE — 99FRD/EZ-66 burners firing above

2.25 GPH

1. 99FRD, EZ-66 burners are shipped with the blank air shutter (behind

fuel unit) installed. This shutter is suitable only for firing rates up to 2.25

GPH.

2. For firing rates over 2.25 GPH, obtain an open type air shutter from

your Carlin dealer. Remove the blank shutter and replace with the open

shutter.

3. The optional open air shutter is suitable for firing rates from 1.50 to

3.00 GPH.

4. To change air shutters, remove the burner fuel unit. (The fuel unit holds

the shutter in place.) Install the correct shutter and replace the fuel

unit.