MN99102 042015

– 8 –

Model 99FRD, 102CRD & EZ-66 Oil Burners — Instruction Manual

2. Prepare Site • Assemble Burner • Mount Burner

(continued)

Attach air tube to housing

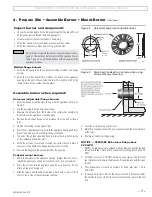

1. See Figure 4. Remove air tube locking screws on the front of the burner

chassis.

2. Open ignitor cover plate by loosening the hold-down tabs and swinging

them away.

3. Spread the housing slightly using a flat screwdriver between the two

halves of the housing on top at the air tube collar.

4. Insert the air tube into the housing, make sure the tube is inserted

completely, butting against the air tube collar legde. If necessary, tap

on the end of the air tube with a block of wood until properly seated.

5. When using 99FRD/EZ-66 wrapped-shield air tube or 102 CRD “B”

style air tube, locate the drip hole in the air cone. Rotate the air tube

so the drip hole is at the bottom before pressing into place.

6. Replace and tighten airt tube locking screws.

Figure 4 Attaching air tube to burner chassis

Mount burner in appliance

Welded flange-mounted burner

1. Place gasket over burner air tube and insert burner into appliance

opening. Secure in place with hardware supplied with appliance.

Universal flange or pedestal mount — these insertion methods

are intended only for negative overfire pressure. For pressur-

ized firing, you must obtain a burner with a welded flange,

designed for use with the specific appliance. Failure to comply

could result in severe personal injury, death or substantial

property damage.

Universal flange-mounted burner

1. Place gasket over burner air tube.

2. Insert burner into appliance.

3. Verify burner is seated level and straight. Adjust flange slightly if neces-

sary.

4. Secure flange to appliance with hardware supplied with appliance.

Pedestal-mounted burner

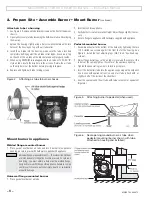

1. Assemble pedestal to the bottom of the burner by tightening the two

¼-20 slotted cap screws against the front feet of the housing. See

Figure 5. Install the four adjusting legs (3/8-16 x 3” hex-head cap

screws).

2. Adjust the pedestal legs so the air tube is level and the center of the

tube is at the same height as the center of the appliance opening.

3. Tighten the pedestal leg jam nuts to lock legs in place.

4. Insert the burner/air tube into the appliance opening until pen/pencil

line is even with appliance front (so end of air tube is flush with, or

slightly short of, the inside of the chamber).

5. Seal the space around the air tube with furnace cement or equivalent

(Figure 6).

Figure 6 Seal opening around burner air tube when

pedestal mounting (burner shown with tube

attached to housing and installed)

Figure 5 Attaching burner to pedestal (when used)