MN99102 042015

– 10 –

Model 99FRD, 102CRD & EZ-66 Oil Burners — Instruction Manual

3. Prepare Burner

(continued)

Inspect the nozzle adapter before replacing the nozzle. If the

threads have been damaged or show score marks, replace

the nozzle line/adapter assembly.

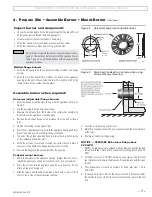

4. Replace the retention ring assembly by slipping one of the riveted arms

through the gap between the electrode tips. Align this arm straight up,

with the ring clamp firmly against the nozzle adapter shoulder (see

Figure 10). Then tighten the clamping screw.

5. Reposition and check the electrode settings. Position the electrodes as

shown in Figure 10. These settings are critical in ensuring a reliable

ignition. Once the electrodes are set, check all clamps to be sure they

are securely tightened.

6. Insert the combustion head/nozzle assembly in the burner.

Check zero position

(99FRD only)

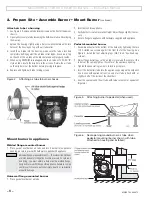

1. See Figures 11, 12 and 13. Loosen the oil line thumb nut and adjusting

slide locking screw. Use a

B\cx

" Allen wrench to rotate the adjusting

screw until the lead edge of the slide aligns to “0” on the scale. The

retention ring should be flush, or nearly flush, with the edge of the

throttling ring.

2. If the retention ring is not close to flush with the throttle ring, make

sure the air tube is completely inserted into the housing collar and the

retention ring clamp is firmly against the nozzle adapter shoulder.

Set initial burner air settings

Combustion head

1. The combustion head adjusting slide controls the spacing between the

retention ring and throttle ring (or air cone), regulating how much air

passes around the retention ring.

2. Loosen the oil line thumb nut and adjusting slide locking screw. Use a

B\cx

" Allen wrench to rotate the adjusting screw until the lead edge of

the slide aligns to the number given in Table 3, page 11. Lock in place

by first tightening the oil line thumbnut, then tightening the locking

screw.

Air shutter

1. The air shutter is fixed for all 99FRD, EZ-66 and 102CRD burners. See

page 7 for the correct air shutter type. (Some 102CRD burners may

be equipped with 3-slot air shutters.)

Air band

1. The air band is marked in percent opening. Loosen the air band locking

screw and move the air band until the pointer lines up with the percent

opening given in Table 3, page 11.

Final adjustments

1. The burner is now adjusted to the approximate air settings for the firing

rate chosen. When you check combustion with instruments during start-

up or servicing, you may have to adjust the head slightly to achieve the

desired efficiency. See “Adjust burner using test instruments,” page 22.

( Note that pressure overfire will reduce air flow, requiring more air

opening.)

Figure 11 Check zero position — 99FRD only

Figure 10 Combustion head/nozzle/electrode settings

Figure 12 Combustion head and air band adjutsments