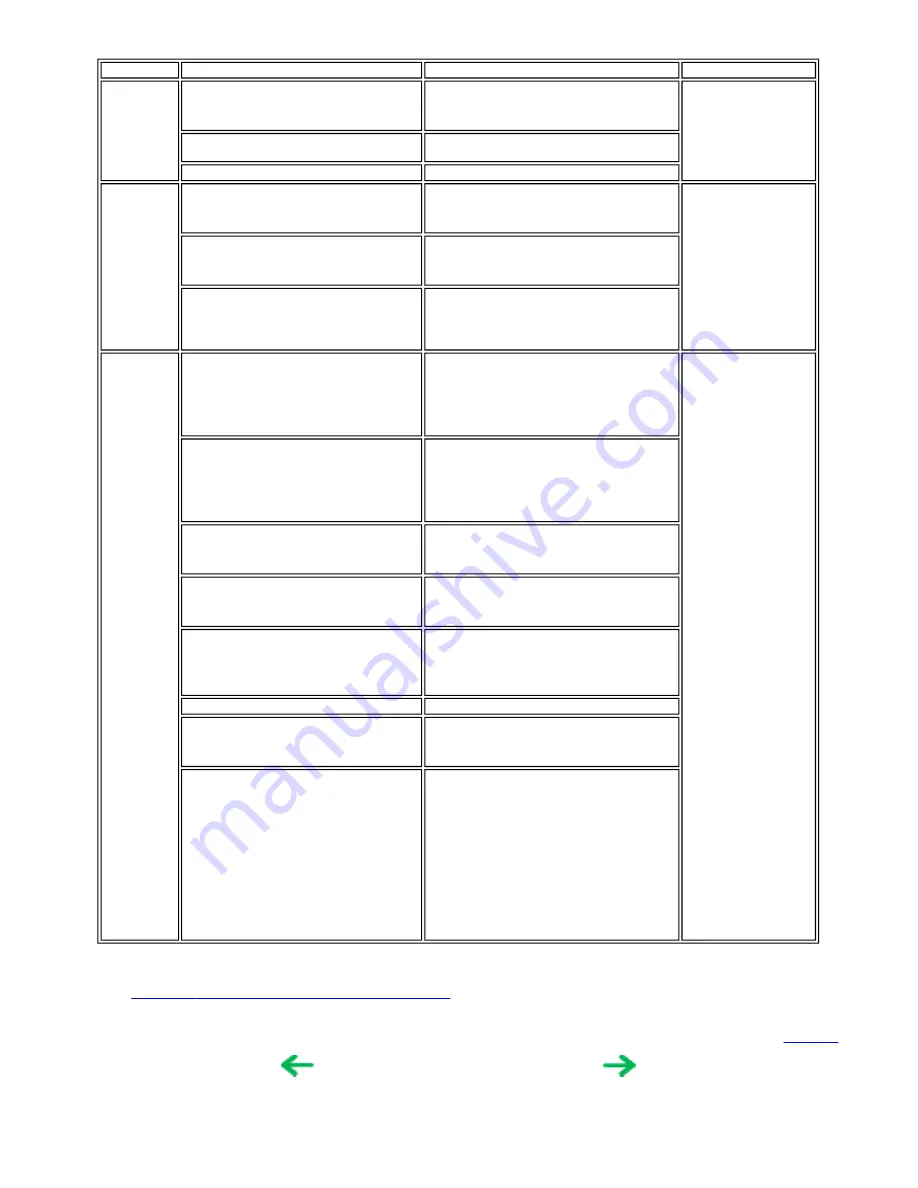

2-4. Troubleshooting by Symptom

*1: Before replacement of the logic board ass'y, check the waste ink amount (by service test print or EEPROM information print). If the waste ink amount is 7%

or more, also replace the bottom case unit (QM2-1496) or the ink absorbers (QC1-4222 / 4223 / 4224 / 4263 / 4264 / 4864 / 4221 / 4257) when replacing

the logic board ass'y.

[See Section 3-3. Adjustment / Settings, (6) Service mode, for details.]

*2: Replace the print head only after the print head deep cleaning is performed 2 times, and when the problem persists.

To the top

Symptom

Solution

Remarks

Faulty operation

The power does not turn on.

The power turns off immediately after power-on.

Replace the

- AC adapter, or

- logic board ass'y*1.

Strange noise.

Remove foreign material, or attach a removed part if

any.

Printing stops mid-way.

Replace the logic board ass'y*1.

Paper feed

problems

Multiple sheets feed.

Replace the

- sheet feed unit, or

- cassette.

Paper does not feed.

Remove foreign material, or replace the

- sheet feed unit, or

- cassette.

Paper feeds at an angle.

Remove foreign material, or adjust the paper guide, or

replace the

- sheet feed unit, or

- cassette.

Unsatisfactory

print quality

No printing, or no color ejected.

Replace the

- ink tank,

- print head*2,

- logic board ass'y*1, or

- purge unit.

Printing is faint, or white lines appear on printouts

even after print head cleaning.

Line(s) not included in the print data appears on

printouts.

Remove and re-install the print head, or replace the

- ink tank,

- print head*2,

- purge unit, or

- logic board ass'y*1.

Paper gets smeared.

Feed several sheets of paper,

perform bottom plate cleaning, or

clean the paper path with cotton swab or cloth.

A part of a line is missing on printouts.

Replace the

- ink tank, or

- print head*2.

Color hue is incorrect.

Replace the

- ink tank, or

- print head*2, or

perform print head alignment.

Printing is incorrect.

Replace the logic board ass'y*1.

No ejection of black ink.

Replace the

- ink tank, or

- print head*2.

Graphic or text is enlarged on printouts.

When enlarged in the carriage movement direction,

clean grease or oil off the timing slit strip film, or

replace the

- timing slit strip film,

- carriage unit, or

- logic board ass'y*1.

When enlarged in the paper feed direction, clean

grease or oil off the timing slit disk film, or replace the

- timing slit disk film,

- timing sensor unit, or

- logic board ass'y*1.

<Part 1: 2. LIST OF ERROR DISPLAY / INDICATION>

1 - 5

Summary of Contents for PIXMA iP6000D

Page 7: ...Part 1 MAINTENANCE ...

Page 17: ... 3 Grease application 1 10 ...

Page 27: ...Part 2 TECHNICAL REFERENCE ...