Chapter 8

8-78

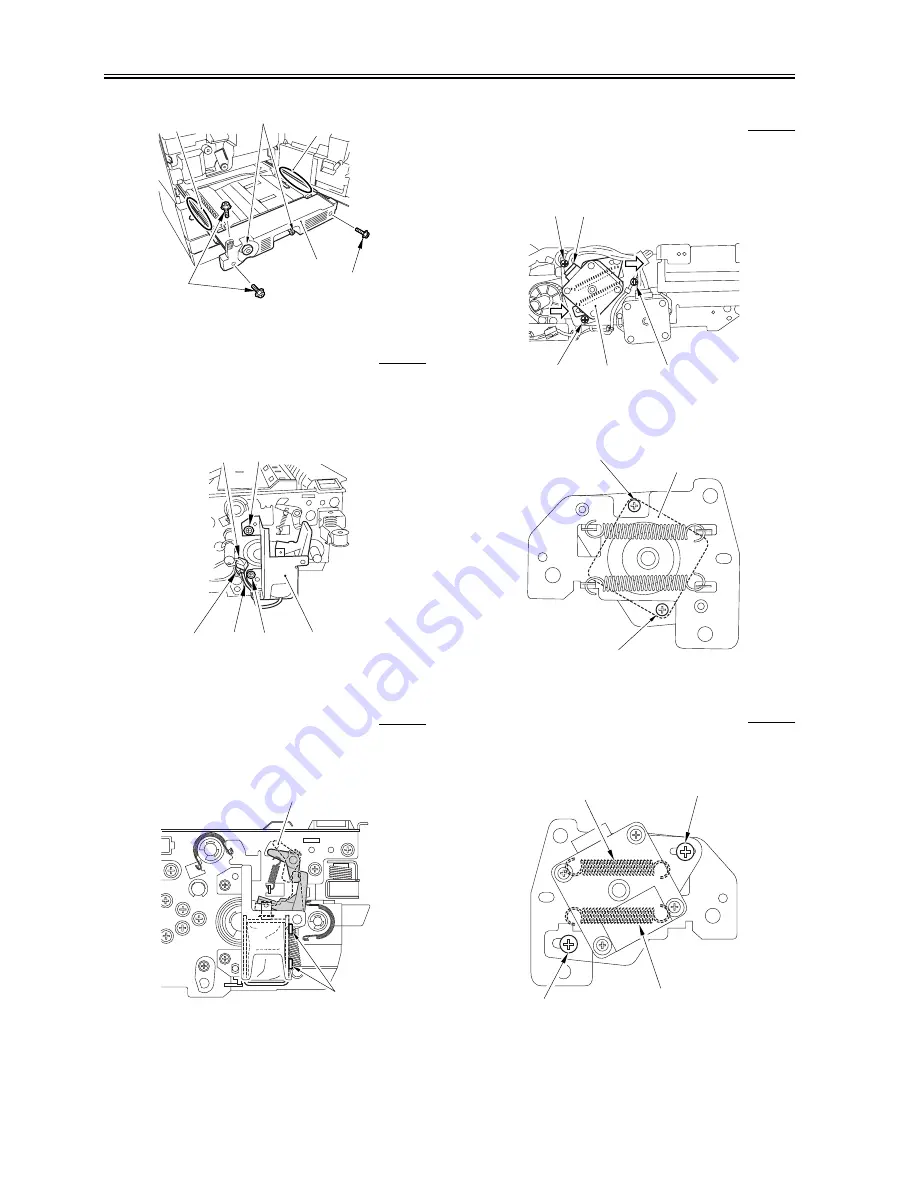

F-8-248

8.10.27.2 Removing the Reversing Flapper Solenoid

0009-5162

1) Disconnect the connector [1], and free the harness [3] from the guide

[2].

2) Remove the two mounting screws [4], and detach the reversing

flapper solenoid [5].

F-8-249

8.10.27.3 Adjusting the Position of the Reversing Flapper

Solenoid (SL8)

0009-5163

1) Adjust the potion of the so-lenoid so that the drive lever [1] is pushed

fully when the solenoid turns on (i.e., when the plunger is drawn).

F-8-250

8.10.27.4 Removing the Reversal Motor

0009-5164

1) Disconnect the connector [1].

2) Remove the three mounting screws [2], and detach the reversal motor

[3] together with its support plate.

F-8-251

3) Remove the two mounting screws [1], and detach the reversal motor

[2] from the support plate.

F-8-252

8.10.27.5 Mounting the Reversal Motor

0009-5167

1) While the spring [1] has most tension, tighten the two mounting

screws [2] temporarily.

F-8-253

2) Mount the support plate [2] (2 pc.) and the motor [3] using three

[2]

[3]

[4]

[4]

[1]

[1]

[1]

[2]

[3]

[4]

[5]

[4]

[1]

[2]

[2]

[3]

[2]

[1]

[2]

[1]

[1]

[2]

[1]

[1]

[2]

[2]

Summary of Contents for iR6570 series

Page 1: ...Mar 29 2005 Service Manual iR6570 5570 Series...

Page 2: ......

Page 6: ......

Page 26: ...Contents...

Page 27: ...Chapter 1 Introduction...

Page 28: ......

Page 30: ......

Page 55: ...Chapter 2 Installation...

Page 56: ......

Page 58: ...Contents 2 9 3 Mounting the Cassette Heater 2 34...

Page 98: ......

Page 99: ...Chapter 3 Basic Operation...

Page 100: ......

Page 102: ......

Page 110: ......

Page 111: ...Chapter 4 Main Controller...

Page 112: ......

Page 114: ......

Page 135: ...Chapter 5 Original Exposure System...

Page 136: ......

Page 181: ...Chapter 6 Laser Exposure...

Page 182: ......

Page 184: ......

Page 192: ......

Page 193: ...Chapter 7 Image Formation...

Page 194: ......

Page 198: ......

Page 259: ...Chapter 8 Pickup Feeding System...

Page 260: ......

Page 350: ......

Page 351: ...Chapter 9 Fixing System...

Page 352: ......

Page 401: ...Chapter 10 External and Controls...

Page 402: ......

Page 406: ......

Page 448: ......

Page 449: ...Chapter 11 MEAP...

Page 450: ......

Page 452: ......

Page 455: ...Chapter 12 Maintenance and Inspection...

Page 456: ......

Page 458: ......

Page 468: ......

Page 469: ...Chapter 13 Standards and Adjustments...

Page 470: ......

Page 505: ...Chapter 14 Correcting Faulty Images...

Page 506: ......

Page 508: ......

Page 537: ...Chapter 15 Self Diagnosis...

Page 538: ......

Page 540: ......

Page 565: ...Chapter 16 Service Mode...

Page 566: ......

Page 568: ......

Page 633: ...Chapter 17 Upgrading...

Page 634: ......

Page 636: ......

Page 641: ...Chapter 17 17 5 F 17 4 HDD Boot ROM Flash ROM System Software...

Page 646: ...Chapter 17 17 10 F 17 11 8 Click START F 17 12...

Page 675: ...Chapter 17 17 39 F 17 59 2 Select the data to download F 17 60 3 Click Start...

Page 677: ...Chapter 18 Service Tools...

Page 678: ......

Page 680: ......

Page 683: ...Mar 29 2005...

Page 684: ......