13

The appliance and its individual gas shut-off valve must be

disconnected from the supply piping when pressure testing

the gas supply piping at pressures above ½ PSI

Table 8: Gas Pressures at Inlet to Appliance

PROPANE

NATURAL

GAS

Minimum (inches W.C.)

11

3

Maximum (inches W.C.)

11

14

*Recommended regulator settings is 7.0” w.c.

The gas supply line must be of adequate size to prevent

undue pressure drop and must never be smaller than the

size of the connection on the appliance. Sizing based on

Table 8 is recommended, depending on model.

Before operating the appliance, the complete gas train and

all connections must be tested using soap solution.

Verify that the appliance is supplied with the type of gas

specified on the rating plate. Heating values of local natural

gas are to be between 950 and 1010 Btu/ft

3

. Consult factory

if heating values are outside this range or if a gas with a

mixture of constituents is being used.

3.4

CHECKING GAS SUPPLY PRESSURE

•

Turn the main power switch to “OFF” position.

•

Shut off gas supply at the manual gas cock in the gas

piping to the appliance. If fuel supply is LP gas, shut off

gas supply at the tank.

•

Remove the 1/8" hex plug from the gas pressure test

port located on the inlet gas supply connection at the

rear of the appliance. Install a fitting in the inlet

pressure tapping suitable to connect to a manometer

or magnahelic gauge. Range of scale should be 0 to

14 inch W.C. or greater to check inlet pressure

•

Turn on gas supply at the field installed manual gas

cock; turn on LP gas at tank if required.

•

Turn the power switch to “ON” position.

•

Adjust the thermostat set point to call for heat.

•

Observe the gas supply pressure as the burner fires at

100% of rated input. Supply pressure is to remain

stable.

•

Ensure inlet pressure is within specified range.

Minimum and maximum gas supply pressures are

specified in Table 8.

•

If gas pressure is out of range, contact the gas utility,

gas supplier, qualified installer or service agency to

determine necessary steps to provide proper gas

pressure to the control.

•

If gas supply pressure is within normal range, proceed

to remove gas manometer and replace pressure tap

fittings in the gas piping to the appliance. Turn the

power switch to “OFF” position.

•

Turn on gas supply at the manual valve; turn on LP

gas at tank if required.

•

Turn the power switch to “ON” position.

•

Adjust the thermostat temperature set point to the

desired water temperature so the appliance will call for

heat.

•

Check appliance performance by cycling the system

while you observe burner response. The burner should

ignite promptly. Flame profile should be stable, see

section 10.2, Visually Check Main Burner Flames. Turn

system off and allow burner to cool, then cycle burner

again

to

ensure

proper

ignition

and

flame

characteristics.

IMPORTANT

Upon completion of initial installation or following any repair

work on the gas system, leak test all gas connections with a

soap solution while the main burner is firing. Immediately

repair any leak found in the gas train or related components.

DO NOT operate an appliance with a leak in the gas train,

valves or related gas piping.

3.5

HIGH and LOW GAS PRESSURE SWITCHES

(Optional)

High and low gas pressure switches are available as an

option and are wired in series with the blocked flue switch.

The high gas pressure switch is used to monitor the

differential gas pressure between the outlet of the control

valve and the fan inlet. If differential gas pressure exceeds the

maximum setting of the pressure switch, the appliance will

shut down and a low air condition will be indicated on the

display panel. The low gas pressure switch is to monitor the

minimum incoming gas supply pressure supplied to the gas

train. If gas pressure falls below the minimum setting of the

pressure switch, the appliance will shut down and a low air

condition will be displayed on the display panel.

3.6

AIR/GAS RATIO VALVE

The main gas valve supplying gas to the burner on this

appliance utilizes a servo pressure regulator providing a slow

opening, fast closing safety shut off and air/gas ratio control

for the gas combustion process. The valve is a 1:1 negative

pressure gas valve. The valve performs the functions of a

pressure regulator, safety shutoff, and air/gas ratio control.

Full closing of the valve seat occurs in less than 0.8 seconds

when the valve is de-energized. Operation of the gas valve in

combination with the combustion air fan allows the burner

input rate to vary from 20% to 100% based on temperature

demand. The inlet gas supply pressure must be maintained

within the specified minimum and maximum pressures.

The air/gas ratio is preset at the factory and adjustment is not

usually required if gas supply pressure is maintained within

the specified range.

There are no serviceable parts on the air/gas ratio valve

control.

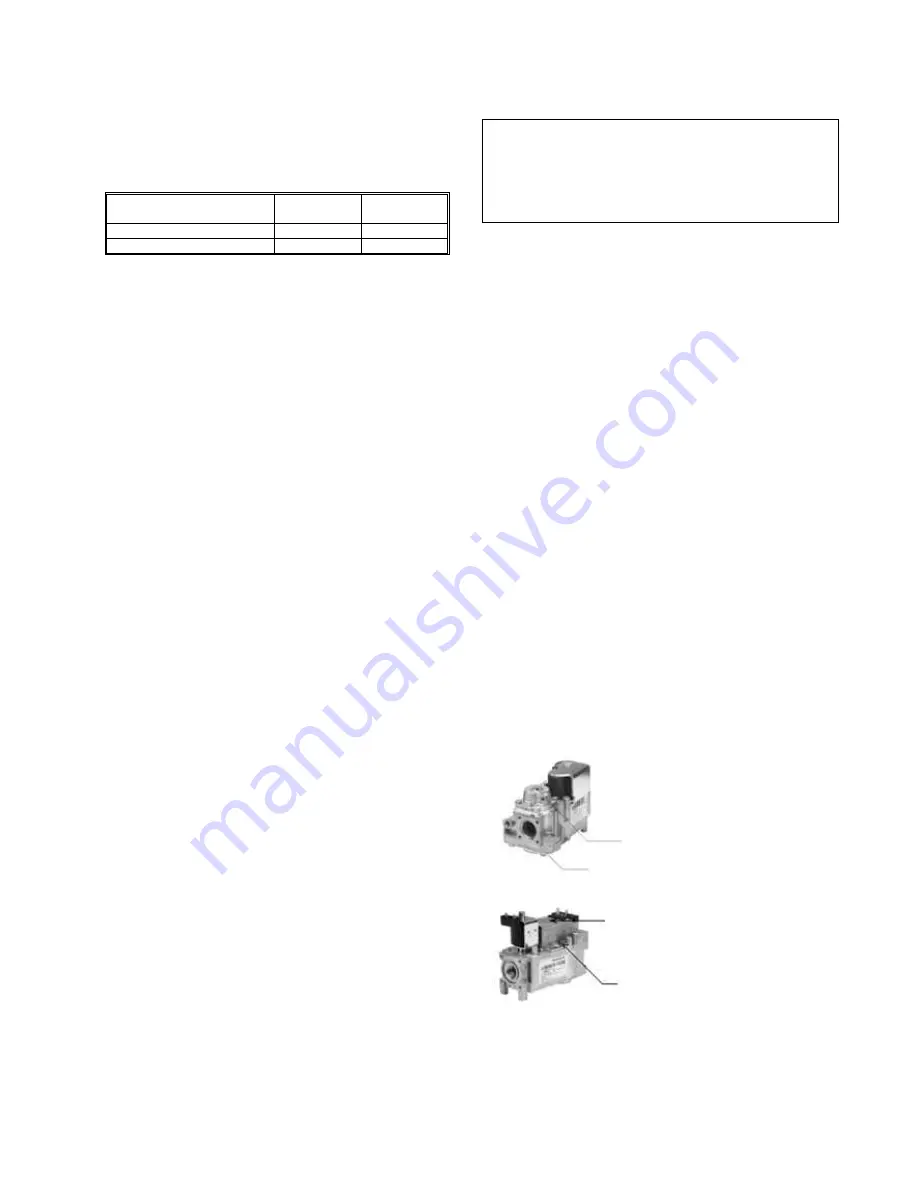

Figure 12: TH 82 – 252 1:1 Air/Gas Ratio Control Valve

Figure 13: TH 292 – 392 1:1 Air/Gas Ratio Control Valve

High fire adjustment:

use throttle screw

located on venturi

Low fire adjustment

screw Torx 40m

clockwise increases CO

2

Gas Inlet

Low-fire air gas ratio adjustment

(use Torx 40 for adjustment,

clockwise increases CO

2

)

High-fire air gas ratio adjustment (Use

slotted screwdriver for adjustment,

counter-clockwise increases CO

2

)