41

10.3 CLEANING BOILER HEAT EXCHANGER

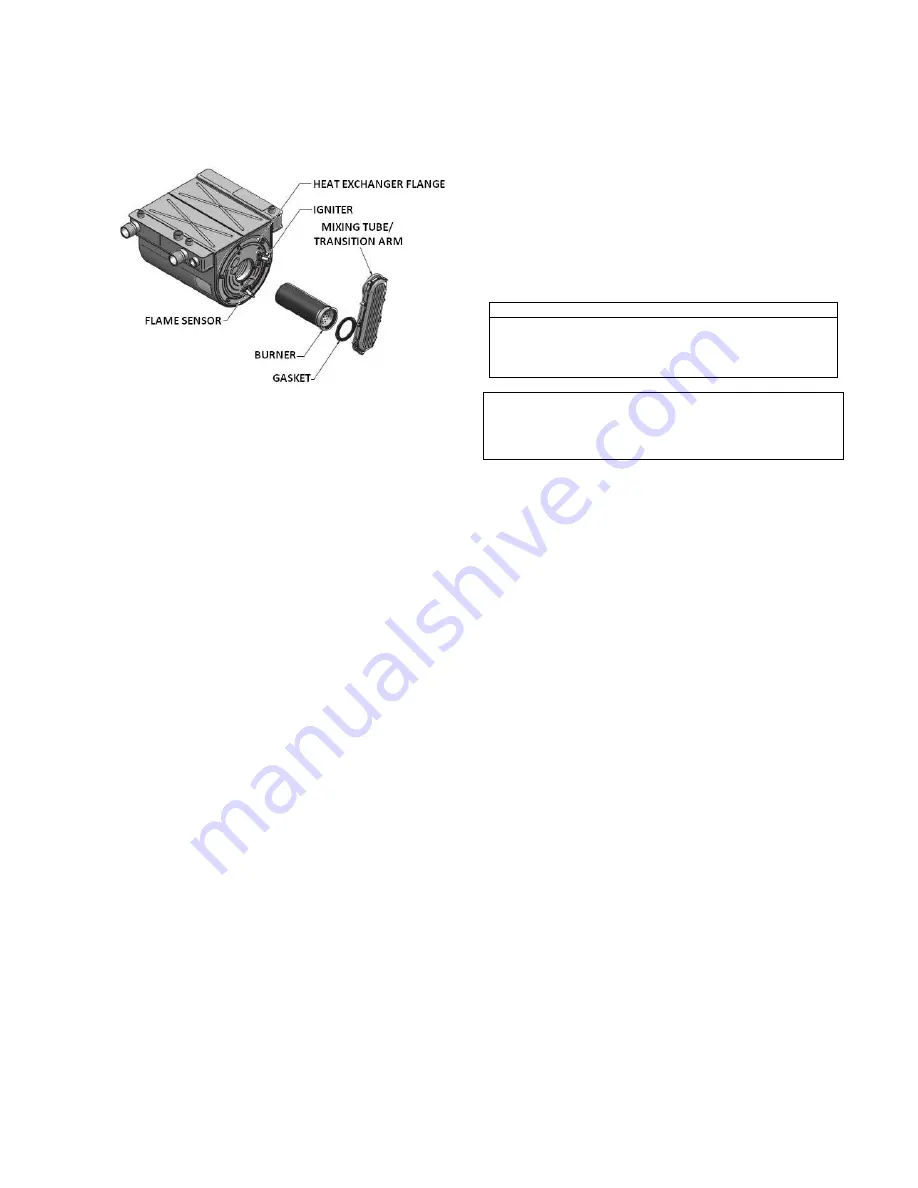

Figure 35: Heat Exchanger & Burner Assembly

1) Shut down boiler:

a) Turn the main power off to the boiler

b) Shut off gas supply at the main manual valve in

the gas piping of the main appliance

c) DO NOT drain the boiler unless it will be exposed

to freezing temperatures. If using antifreeze

prevention fluid in the heat exchanger, DO NOT

drain.

2) Allow time for the boiler to cool to room temperature if it

has been firing.

3) Remove the upper sheetmetal jacket.

4) Remove igniter and flame sensor electrodes. If

necessary, clean with steel wool. DO NOT use

sandpaper.

5) Remove the fan/ mixing tube assembly from the heat

exchanger door.

6) Remove burner.

7) Examine burner and clean if required as per 10.7.1.

8) Examine heat exchanger surfaces to determine if

cleaning is required. If cleaning is required remove the

(6) nuts fastening the heat exchanger flange from the

heat exchanger.

9) Disconnect the condensate hose from the heat

exchanger and connect a 5/8” diameter hose (field

supplied) from the bottom of the heat exchanger to a

drain

10) Use water proof material to carefully cover the refractory

at the rear of the combustion chamber of the heat

exchanger

11) Use a vacuum cleaner to remove any debris that has

collected on the heat exchanger surfaces. DO NOT use

any type of solvent.

12) Brush the heat exchanger with a nylon bristle brush. DO

NOT use a metal brush. Re-vacuum the heat

exchanger.

13) Finish cleaning by wiping down the boiler heating

surfaces with a clean, damp cloth.

14) Rinse out any additional debris with a low pressure

water supply. Start rinsing from the rear of the heat

exchanger and slowly working your way towards the

front of the heat exchanger.

15) Remove the water proof material after cleaning is

complete.

16) Re-install the heat exchanger door by evenly torquing

down the (6) nuts to 3 ft-lbs, burner, igniter and flame

sensor, and fan/ mixing tube assembly. Fasten the nuts

back to the heat exchanger assembly.

17) Re-connect the fan assembly to the boiler mixing tube.

18) Re-connect the condensate hose to the heat exchanger.

NOTE

All gaskets on disassembled components must be replaced

with new gaskets/sealant on re-assembly, if required. Gasket

kits are available from the factory

CAUTION

When the vent system is disconnected for any reason it must

be

reassembled

and

resealed

according

to

vent

manufacturer’s instruction

10.4

CONDENSATE TREATMENT

Condensate occurs when the products of combustion are

cooled below their dew point in the heat transfer process.

The liquid condensate formed from this high efficiency heat

transfer process is mildly acidic. The condensate will

typically have a pH ranging from 4.0 to 5.0 as it is

discharged from the condensate drain of the appliance. The

condensate collection box where the condensate is collected

is constructed of a non-corrosive plastic. All materials

external to the appliance in contact with the condensate

must be corrosion resistant. Condensate must be able to

flow freely from the appliance. All condensate flow is

accomplished by gravity requiring a minimum downward

slope of 1/4” per foot (21mm/m) to ensure proper flow to a

suitable drain. A neutralizer box is mounted inside each TH.

All condensate piping and connections must be easily

accessible for routine maintenance and inspection. Use solid

piping when running condensate line across the floor. Check

neutralized pH level regularly or as required by local

jurisdiction. Replace neutralizer medium as required.

10.4.1

Condensate Volume

There are several factors affecting amount of condensation

created by the appliance, however for rough approximation

use.

Condensation Volume, US Gallon/Hr = Input, MBH/1000 x

5.0

Many codes will require the acidic condensate to be

neutralized before it can be placed in a drain system. A

neutralizer to control the pH of the liquid discharged to a

drain system is provided with every TH boiler. The

neutralizer consists of an industrial grade, non-corrosive

plastic reservoir for collection of the condensate. The

condensate collects in the reservoir where it is in direct

contact with calcium carbonate neutralizer medium. As the

reservoir fills, it provides an extended residence time to

neutralize the condensate. Residency time in the neutralizer

reservoir allows time for the pH to be raised. Prime the

neutralizer reservoir with 1 litre of water.