10

2.5.2

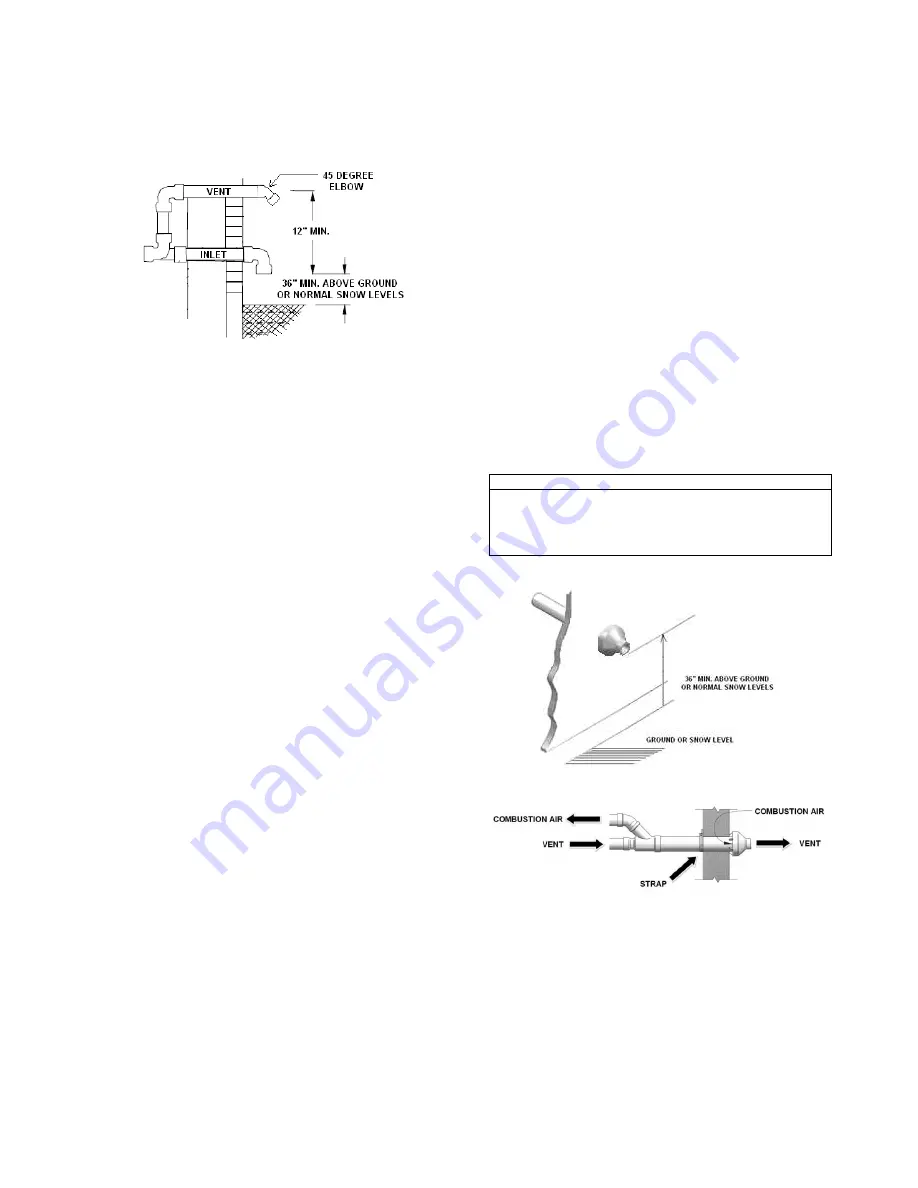

Sidewall Air Inlet

Figure 7: Sidewall Vent and Air Inlet Configuration

* Please check local codes for minimum distance above

ground or snow levels

Location of a Sidewall Air Inlet Cap

1) The total length of piping for air inlet must not

exceed the limits stated in Table 6.

2) The point of termination for the sidewall air inlet

cap must be located a minimum of 12 inches

(0.30m) away from the flue gas termination, but

never above.

3) The air piping must terminate in a down-turned

elbow to avoid recirculation of flue products into

the inlet air stream.

4) DO NOT terminate closer than 4 feet (1.25m)

horizontally and vertically from any electric meter,

gas meter, regulator, relief valve, or other

equipment. In all cases local codes take

precedence

5) DO NOT terminate the air inlet in a window well,

stairwell, alcove, courtyard or other recessed area

as wind eddies could affect performance or cause

recirculation.

6) The air inlet cannot terminate below grade.

7) Locate terminations so they are not likely to be

damaged by foreign objects, or exposed to build-

up of debris.

8) Perform regularly scheduled inspections to ensure

that the air inlet terminal is unobstructed.

Termination and Fittings

1) The air inlet opening must be at least 12 inches

(0.30m) away from (never above) the vent

termination and at least 3 feet (1m) above grade

or above normal maximum snow levels.

2.5.3

Sidewall Concentric Vent/ Air

A listed concentric vent kit can be used with the TH

appliance. Both combustion air and vent pipes must

terminate outside the structure.

1)

The total length of piping for venting or air must not

exceed the limits stated in Table 8.

2)

The bottom of the termination shall be located at

least 3 feet (1m) above grade or above normal snow

levels. In all cases the appliance shall be installed in

accordance with local codes

3)

The termination MUST NOT terminate below a forced

air inlet at any distance

4)

The termination cannot terminate below grade.

Position the termination where vapours will not

damage walls or plants or may be otherwise

objectionable.

5)

The termination shall not be installed closer than 3 feet

(1m) from an inside corner of an L-shaped structure,

window well, stairwell, alcove, courtyard or other

recessed area as wind eddies could affect boiler

performance or cause recirculation.

6)

DO NOT terminate closer than 4 feet (1.25m)

horizontally and vertically from any electric meter, gas

meter, regulator, relief valve, or other equipment. In all

cases local codes take precedence

7)

Position termination so they are not likely to be

damaged by foreign objects, or exposed to a build-up of

debris.

8)

Flue gas condensate can freeze on exterior walls or on

the vent cap. Frozen condensate on the vent cap can

result in a blocked flue condition. Keep the vent

cap/terminal clear of snow, ice, leaves, debris etc.

Some discolouration to exterior building surfaces is to

be expected. Adjacent brick or masonry surfaces

should be protected with a rust resistant sheet metal

plate.

9)

Perform regularly scheduled inspections to ensure that

the termination is unobstructed.

10)

Operate the appliance for one heat cycle to ensure

combustion air and vent pipes are properly connected

to the concentric vent termination connections.

CAUTION

Do not operate appliance with the rain cap removed as this

may result in the recirculation of flue products. Water may

also flow into the combustion air pipe and into the burner

enclosure.

Figure 8: Concentric Sidewall Termination

Figure 9: Concentric Vent Sidewall

2.6

Vertical Direct Venting

Location of Vent Termination

1) The total length of piping for venting must not

exceed the limits stated in Table 6.

2) The vent piping must terminate in a 90

o

elbow if

plastic piping is used or in an approved vent cap if

using metal venting. The vent outlet must be at least

1 foot away and 1 foot above from the air inlet

opening which must terminate in a double elbow

facing downwards.