18

Cleaning on instantaneous

D

p

During normal operation, the device monitors the strainer clogging status, by measuring the differential pressure between inlet and outlet of the strainer

elements measured by the probes S1 and S2. When the difference exceeds a value set and modifiable by the user, an automatic strainer cleaning

cycle is immediately started.

Cleaning on delayed

D

p

When the

D

P exceeds a predefined value (the same used to start the instantaneous cleaning), the cleaning is programmed to be performed but at a

time specified by the user.

Scheduled cleaning

It is possible to carry out a cleaning cycle on a specific day of the week, at a specific time or on several days of the same week. The device is cleaned

anyway even if the maximum set

D

p value is not exceeded during operation. Cleaning can be scheduled for a particular day of the month, every two

months, every three months or every six months.

Initial cleaning

This function can be used after washing the system or anyway whenever an extraordinary cleaning of the system is necessary. Before starting this

function it is necessary to configure the duration. When the set

D

p is reached, a washing cycle is immediately started. When the set number of

hours is reached, the first system cleaning function stops and the normal operating mode starts again, with the washes time management (e.g. once

a week) and/or based on the normal operation

D

p value.

Manual forcing

It is possible to start the operating status through the forcing function, from the user interface or from remote (via bus). Once the required activation is

completed, the device returns to normal operation. Forcing allows, from the user interface, to individually start the cleaning, sleep, additive addition,

sensor control cycles.

Sleep

The sleep mode temporarily deactivates the device, setting it in a waiting status, with the valve V1 closing and without any control on the operation.

This status allows the device to be deactivated for a set time, for example when the system is shut down in the summer. At the end of the sleep

phase, the device resumes normal operation. The notifications for alarms remain active.

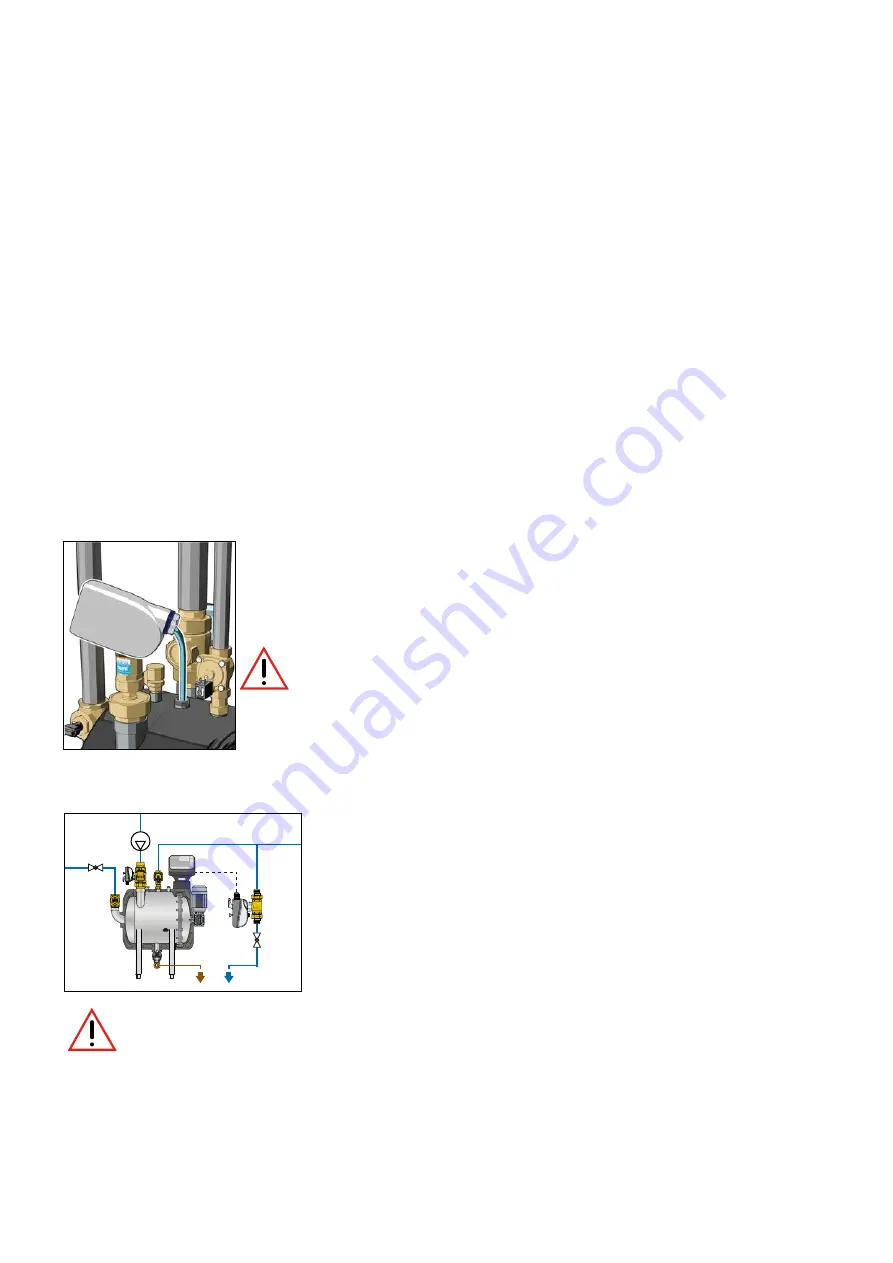

Use of additives

Additives can be added to the system medium activating the appropriate function. In this case the system is

set in stand by, after having carried out a forced cleaning cycle with a view to reducing as much as possible the

use of the water in the network, taking advantage of the tank emptying. During the waiting phase it is possible

to insert the necessary additives into the device using the 1” cap located in the upper part of the strainer, see

the characteristic components drawing. Carefully check the cap watertight closing, in order to prevent leakage

or flooding.

Additives must be in liquid form and must be added carefully and slowly to prevent accidental spills

Check the compatibility between the type of additives used and the dirt separator strainer materials. Any

incompatibility can cause serious damage to the machine, to people and property. Avoid contact with

skin and eyes. Avoid inhalation, use personal protective equipment. Do not disperse in the environment.

Refer to the safety data sheet and the technical documentation of the product. It is advisable to insert

max 40l of additives. If necessary, the function can be executed several times.

Sensors check

The regulator periodically checks the correct operation of the sensors. This procedure can be carried out manually through the item on the regulator

menu.

Drain temperature limitation

The system is provided with a function to cool the water drain when the temperature is higher

than a given value (that can be changed). During cleaning, if the system detects that the medium

temperature is higher than the admissible temperature, the activation of a specific G. OUT relay is

activated, which remains active until the drain ends.

The activation of the G. OUT relay must be used by the user to provide a system for reducing the drain water temperature of the device,

for example through a valve that injects cold water into the drain. Check the local regulations in force.

Faults

Abnormal operating conditions do not stop the operation of the device but are indicated on the display and allow to prevent more serious

problems (red LED flashing on the front panel). For more details about the alarms, refer to the "programming manual" code H0005275.

Alarms

In the event of serious problems that compromise the system safety conditions, it is set into a locked state. The relative status is shown

on the display (red fixed LED on the front panel), in addition the "ALARM" relay sets to the closed position. The latter may possibly be

connected to an optical and/or acoustic alarm system. For more details on the symbols related to the alarms, refer to the "programming

manual" code H0005275.