En-13

5. FINISHING

WARNING

Install the insulated pipes so that they do not touch the compressor.

5.1. Installing insulation

• Install insulation material after conducting “3.6. Sealing test”.

• To prevent condensation and water droplets, install insulation material on the refrigerant

pipe. (Fig. A)

• Refer to the table to determine the thickness of the insulation material.

Selection of insulation

(Use an insulation material with equal heat transmission rate or below 0.040

W/(m·k))

Insulation material minimum thickness (mm)

Relative humidity

≤

70%

≤

75%

≤

80%

≤

85%

Pipe diameter

(mm)

6.35

8

10

13

17

9.52

9

11

14

18

12.70

10

12

15

19

15.88

10

12

16

20

19.05

10

13

16

21

22.22

11

13

17

22

25.40

11

13

17

22

* When the ambient temperature and relative humidity exceed 32 °C (DB) and 85%

respectively, please strengthen the heat insulation of refrigerant pipe.

5.2. Filling with putty

WARNING

Fill the piping holes and wiring holes with putty (locally purchased) to avoid any gap

(Fig. A). If small animals such as insects enter the external unit, a short circuit may be

caused near electrical components in the service panel.

• If the outdoor unit is installed at a level that is higher than the indoor unit, the water

that has condensed in the 3-way valve of the outdoor unit could travel to the indoor

unit. Therefore, use putty in the space between the pipe and the insulation to prevent

the entry of water to the indoor units.

Fig. A

Putty

Insulation

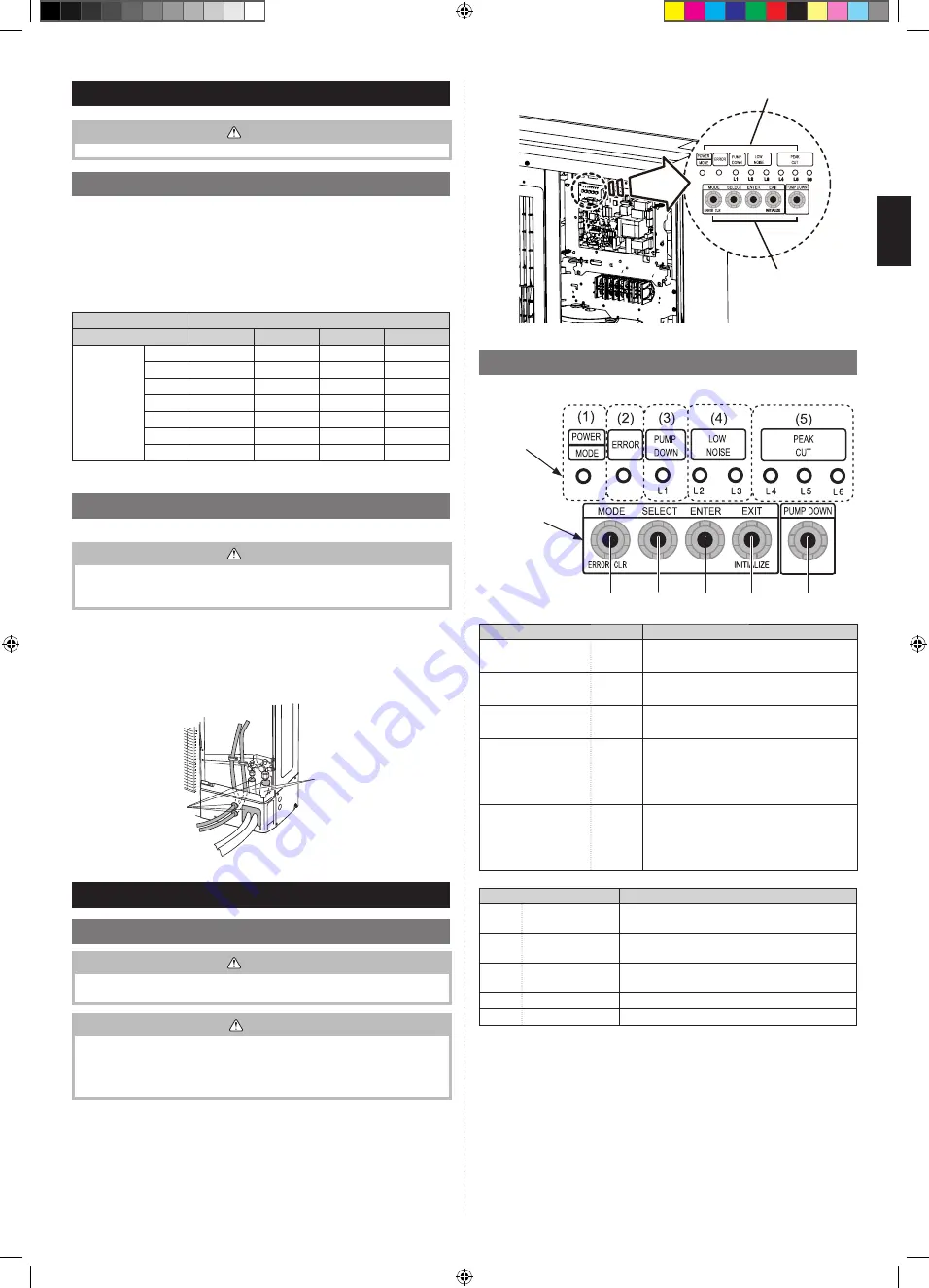

6. HOW TO OPERATE DISPLAY UNIT

6.1. Display unit position

WARNING

Never touch electrical components such as the terminal blocks except the button on

the display board. It may cause a serious accident such as electric shock.

CAUTION

• Once refrigerant charging is completed, be sure to open the valve prior to

performing the local settings. Otherwise, the compressor may fail.

• Discharge any static electricity from your body before touching the push buttons.

Never touch any terminal or pattern of any parts on the control board.

• The positions of the buttons on the outdoor unit control board are shown in the

following

fi

gure.

• Various settings can be adjusted by changing push buttons on the board of the outdoor

unit.

Push buttons

LED display

6.2. Description of display and buttons

• The printed characters for the LED display are shown below.

S134

S133

S132

S131

S130

LED display part

Button part

Display lamp

Function or operation method

(1) POWER / MODE

Green

Lights on while power on. Local setting in out-

door unit or error code is displayed with blink.

(2) ERROR

Red

Blinks during abnormal air conditioner

operation.

(3) PUMP DOWN

(L1)

Orange

Lights on during pump down operation.

(4) LOW NOISE

(L2, L3)

Orange

Lights on during Low noise mode when local

setting is activated. (Lighting pattern of L2 and

L3 indicates low noise level)

*Refer to the page 14.

(5) PEAK CUT

(L4, L5, L6)

Orange

Lights on during Peak cut mode when local

setting is activated. (Lighting pattern of L4, L5

and L6 indicates peak cut level)

*Refer to the page 15.

Button

Function or operation method

S134

MODE

To switch between “Local setting” and “Error code

display”.

S133

SELECT

To switch between the individual “Local settings”

and the “Error code displays”.

S132

ENTER

To

fi

x the individual “Local settings” and the “Error

code displays”.

S131

EXIT

To return to “Operation status displays.”

S130

PUMP DOWN

To start the pump down operation.

9379069953_IM.indb 13

9379069953_IM.indb 13

5/24/2019 9:59:20 AM

5/24/2019 9:59:20 AM