INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 8 of 67

3.0 SAFETY DEVICES

PERIODICALLY, AT LEAST MONTH-

LY, CHECK THE INTEGRITY AND

THE FUNCTIONALITY OF THE

SAFETY AND PROTECTION DE-

VICES ON THE MACHINE.

•

Non-adjustable pressure limiter

.

This allows inflation of tyres in reasonable safety.

Inflation of tyres to over 4,2 ± 0,2 bar (60 PSI) is

not allowed.

•

Controls logic disposition

Its function is to prevent the operator from danger-

ous mistakes.

•

Motor protection devices

The new “Invemotor” motor is equipped with elec-

tronic protection devices. They stop the motor if

working defected conditions appear to avoid that the

motor itself can be damaged and that the operator

safety can be compromised (overvoltage, overload,

overtemperature).

•

Emergency push button

The “Emergency push button” (

Fig. 14 ref. I

) has

two fixed operative functions:

- pressed push button: all control unit functions are

interrupted and the supply to the machine electri-

cal panel is interrupted, except for the control PC.

- lifted push button: reset of machine functions.

•

Emergency start

The machine is equipped with a control mechanism

requiring some operations and/or checks in case

of anomalous switch-off (in case of power lack, for

instance). After confirmation through push-button

panel, the functions are reset and the machine emer-

gency condition is cancelled.

•

Assent pedal

In automatic functioning (from PC) this pedal ena-

bles machine automatic functioning. When the pedal

released, the machine automatically stop. When

lowered, the machine operations are reset.

3.1

Residual risks

The machine was subjected to a complete analysis of

risks according to reference standard EN ISO 12100.

Risks are as reduced as possible in relation with tech-

nology and product functionality.

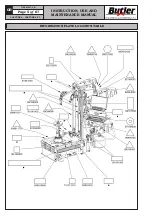

Possible residual risks have been emphasized through

pictorial representations and warnings which placing is

indicated in “ PLATE POSITIONING TABLE” at page 5.

4.0 GENERAL SAFETY RULES

• Any tampering with or modification to the machine

not previously authorized by the manufacturer ex-

empts the latter from all responsibility for damage

caused by or derived from said actions.

• Removing of or tampering with the safety devices or

with the warning signals placed on the machine leads

to serious dangers and represents a transgression of

European safety rules.

• Use of the machine is only permitted in places free

from

explosion

or

fire

hazard and in

dry places

under cover

.

• Original spare parts and accessories should be used.

THE MANUFACTURER DENIES

ANY RESPONSIBILITY IN CASE

OF DAMAGES CAUSED BY UNAU-

THORIZED MODIFICATIONS OR

BY THE USE OF NON ORIGINAL

COMPONENTS OR EQUIPMENT.

• Installation must be conducted only by qualified

personnel exactly according to the instructions that

are given below.

• Ensure that there are no dangerous situations dur-

ing the machine operating manoeuvres. Immediately

stop the machine if it miss-functions and contact the

assistance service of an authorized dealer.

• In emergency situations and before carrying out any

maintenance or repairs, disconnect all supplies to

the machine by using the main switch, placed on the

machine itself, and unplugging the power supply.

• The machine electrical supply system must be

equipped with an appropriate earthing, to which

the yellow-green machine protection wire must be

connected.

• Ensure that the work area around the machine is free

of potentially dangerous objects and that there is no

oil since this could damage the tyre. Oil on the floor

is also a potential danger for the operator.

• UNDER NO CIRCUMSTANCES must the machine be

used to spin anything but vehicle wheels. Bad locking

can cause rotating parts to come loose, with potential

damage to the machine and anything in the vicinity

and injury to the operator.

CAPTURE 4 - CAPTURE 4 FI

7104-M007-4_B