INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 30 of 67

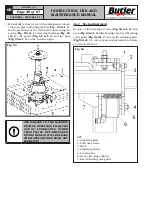

5 - Rotate clockwise the small internal levers (

Fig. 24A

ref. 1

), until they reach the outer levers (

Fig. 24A

ref. 2

) in order to unlock the ring-nut. Make the

rink-nut (

Fig. 24A ref. 3

) and the cone (

Fig. 24A

ref. 4

) approach the rim (

Fig. 24A ref. 5

). Release

the small inner levers (

Fig. 24A ref. 1

) the ring-nut

gets locked on the threaded shaft (

Fig. 24A ref. 6

).

Fig. 24A

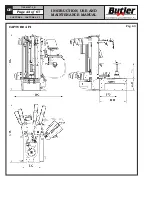

6 - Turn the ring nut (

Fig. 24B ref. 1

) clockwise

through the external levers (

Fig. 24B ref. 2

) until

the cone complete clamping (

Fig. 24B ref. 3

) on

the rim (

Fig. 24B ref. 4

).

Fig. 24B

7 - At the end of the operations, unlock the ring nut

by loosening first the cone with the external levers

and then moving the ring nut and the cone away

from the rim with the small levers.

Place the locking ring-nut onto its own activator

support.

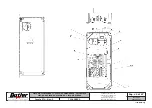

IN CASE THE PNEUMATIC SYS-

TEM FOR THE LIFTING OF THE

THREADED CENTRAL SHAFT

DOES NOT WORK (IN ORDER

TO CONTINUE WORKING UNTIL

THE REPAIR HAS BEEN CAR-

RIED OUT), LIFT MANUALLY THE

CENTRAL SHAFT

(

Fig. 25 ref. 1

)

UNTIL ITS MAXIMUM HEIGHT,

REMOVE THE PROTECTION CAP

(

Fig. 25 ref. 2

)

AND TIGHTEN THE

DOWEL

(

Fig. 25 ref. 3

)

TO LOCK

THE SHAFT INTO “COMPLETELY

LIFTED” POSITION.

WHEN THE REPAIR HAS BEEN

COMPLETED, SLACKEN THE

DOWEL TO RESET THE CORRECT

FUNCTIONING OF THE PNEU-

MATIC LIFTING DEVICE FOR THE

THREADED SHAFT.

Fig. 25

CAPTURE 4 - CAPTURE 4 FI

7104-M007-4_B