INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 32 of 67

13.3.2 Tyre bead breaking and demount-

ing with manual controls (in “MAN”

mode)

Carry out the following operations after the wheel has

been locked onto the mandrel:

1. Position the selector (

Fig. 28 ref. 1

) on “MAN”.

2. Use the manual controls to position the upper bead

breaking roll (

Fig. 1

and

2 ref. 3

) on the wheel rim.

3. Activate the wheel clockwise rotation.

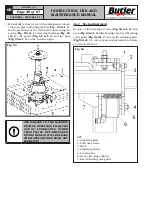

4. Move the lower roll (

Fig. 29 ref. 1

) near with the

push button (

Fig. 14 ref. E

).

1

Fig. 29

5. Press the assent pedal (

Fig. 16 ref. A

) to rotate the

wheel in clockwise direction and at the same time

operate the push button (

Fig. 14 ref. E

) until creat-

ing a space large enough for the roll to progress with

the manual cam. Activate the lower cam pushing

the push button (

Fig. 14 ref. C

) and keep on bead

breaking until the operation is complete.

6. Once bead breaking has been completed in the lower

part, move lower roll in the rest position activating

the push button (

Fig. 14 ref. E

). The roll re-enters

automatically nullifying the cam approaching move-

ment. This automatism can be applied on both

arms.

7. Rotate the rim until the valve is positioned on the

immediate right of the roll.

8. For the upper edge bead breaking the instructions

described above must be followed, but using the

push buttons related to the upper roll (

Fig. 14

ref. B

and

F

).

UNTIL BOTH UPPER AND LOWER

ROLLS DO NOT RE-ENTER, IS NOT

POSSIBLE TO CARRY OUT A NEW

DIAMETER ADJUSTMENT.

When both beads are broken, the tyre can be de-

mounted.

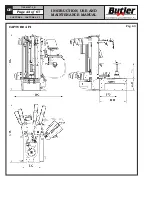

9. Press the assent pedal (

Fig. 16 ref. A

) to rotate the

wheel in clockwise direction until the valve stem

is next to the upper bead breaking roll (

Fig. 30

ref. 1

).

Fig. 30

1

2

10. Position the upper tool (

Fig. 30 ref. 2

) just next

the rim edge using the provided control (

Fig. 14

ref. H

) (upper tool descent) (see

Fig. 32

). While

this phase is being carried out, stay just next to

a zone in the tyre where bead breaking has been

effectuated.

Wheels with rim protector

With this type of tire, there could be cases where

the rim protector doesn’t allow the upper tool to

insert between the rim and the tire (as represented

in

Fig. 31

).

Fig. 31

In these cases, turn the wheel clockwise, with

a slight pressure with the tool as described in

Fig. 32

. In case of rim protectors with particular

shapes, let the wheel turn counter-clockwise.

Fig. 32

CAPTURE 4 - CAPTURE 4 FI

7104-M007-4_B