9

1. Open all electrical disconnects before starting any service

work.

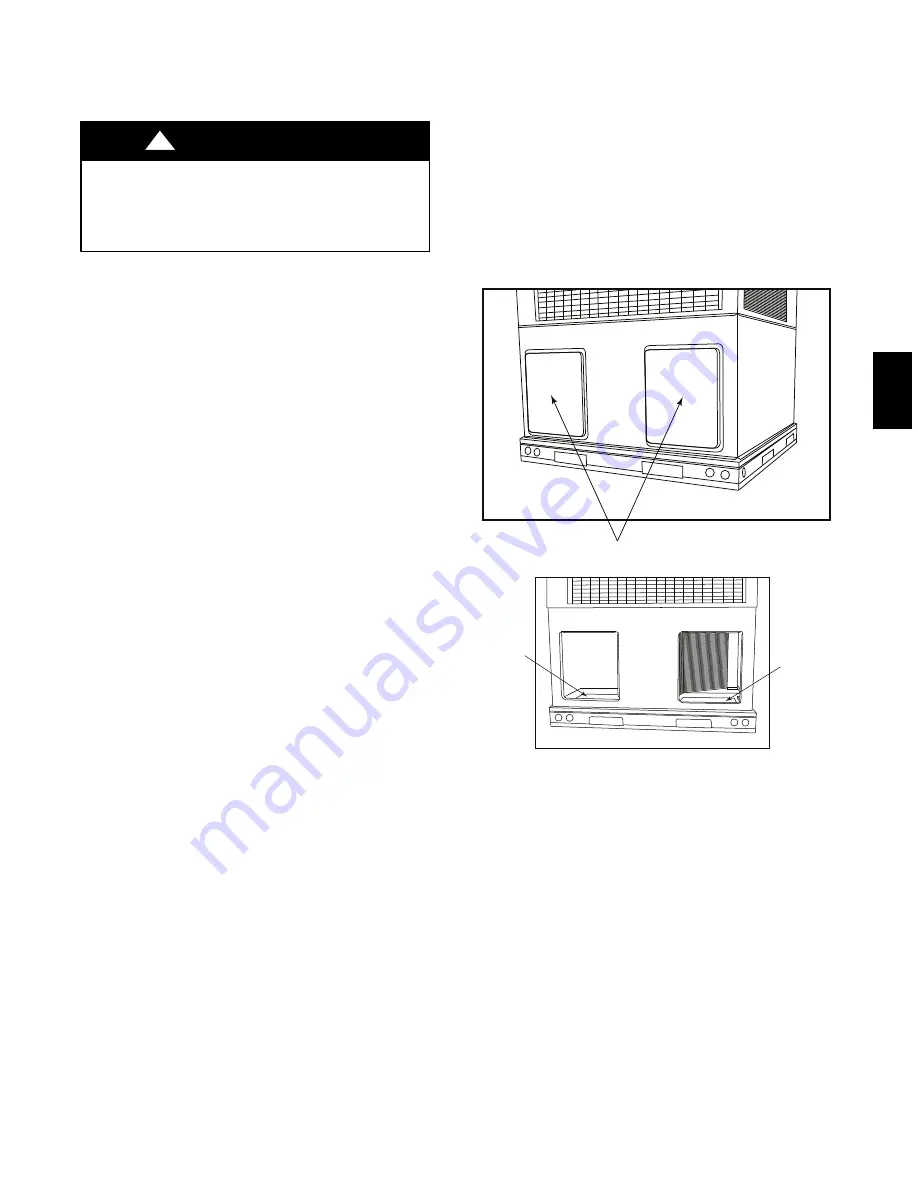

2. Remove horizontal (metal) duct covers to access vertical

(downflow) discharge duct knockouts in unit basepan. (See

Fig. 8.)

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property damage.

Collect ALL screws that were removed.

Do not

leave screws

on rooftop as permanent damage to the roof may occur.

CAUTION

!

3. For single--phase models only, on the discharge side only,

remove the insulation covering the downshot (plastic)

knockout. Insulation is held in place with aluminum tape.

Please note that large chassis units have 2 pieces of insula-

tion, and only the piece over the downshot knockout needs

to be removed. Discard insulation.

4. To remove the downshot (plastic) knockouts for both sup-

ply and returns, break front and right side connecting tabs

with a screwdriver and hammer. Push cover down to break

rear and left side tabs. These plastic knockouts are held in

place with tabs similar to an electrical knockout. Discard

plastic knockout covers.

5. Set unit on roof curb.

6. Verify that the downshot ducts are aligned with the down-

shot knockout areas.

7. Re--install horizontal (metal) covers as needed to seal unit.

Ensure opensings are air and watertight.

NOTE

: The design and installation of the duct system must be in

accordance with the standards of the NFPA for installation of

nonresidence--type air conditioning and ventilating systems, NFPA

90A or residence--type, NFPA 90B; and/or local codes and

ordinances.

Adhere to the following criteria when selecting, sizing, and

installing the duct system:

1. Units are shipped for horizontal duct installation (by

removing duct covers).

2. Select and size ductwork, supply--air registers, and

return--air grilles according to American Society of Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE)

recommendations.

3. Use flexible transition between rigid ductwork and unit to

prevent transmission of vibration. The transition may be

screwed or bolted to duct flanges. Use suitable gaskets to

ensure weather tight and airtight seal.

4. All units must have field--supplied filters or accessory filter

rack installed in the return--air side of the unit.

Recommended sizes for filters are shown in Table 1.

5. Size all ductwork for maximum required airflow (either

heating or cooling) for unit being installed. Avoid abrupt

duct size increases or decreases or performance may be

affected.

6. Adequately insulate and weatherproof all ductwork located

outdoors. Insulate ducts passing through unconditioned

space, and use vapor barrier in accordance with latest issue

of Sheet Metal and Air Conditioning Contractors National

Association (SMACNA) and Air Conditioning Contractors

of America (ACCA) minimum installation standards for

heating and air conditioning systems. Secure all ducts to

building structure.

7. Flash, weatherproof, and vibration--isolate all openings in

building structure in accordance with local codes and good

building practices.

Horizontal Duct Covers

A09061

Basepan

Downflow

(Vertical)

Supply

Knockout

Basepan

Downflow

(Vertical)

Return

Knockout

A09088

Fig. 8 -- Supply and Return Duct Opening

677C

--

--

C

Summary of Contents for Legacy 677C**C Series

Page 3: ...3 A150538 Fig 2 24 30 Unit Dimensions 677C C...

Page 4: ...4 A150539 Fig 3 36 60 Unit Dimensions 677C C...

Page 44: ...44 A150506 Fig 15 208 230 1 60 Connection Wiring Diagram 677C C...

Page 45: ...45 A150516 Fig 15 Cont 208 230 1 60 Ladder Wiring Diagram 677C C...

Page 46: ...46 A150507 Fig 16 208 230 3 60 Connection Wiring Diagram 677C C...

Page 47: ...47 A150517 Fig 16 Cont 208 230 3 60 Ladder Wiring Diagram 677C C...