51

between the coils. Be sure to flush all dirt and debris from the unit

base.

Inspect the drain pan and condensate drain line when inspecting

the coils. Clean the drain pan and condensate drain by removing all

foreign matter from the pan. Flush the pan and drain tube with

clear water. Do not splash water on the insulation, motor, wiring, or

air filter(s). If the drain tube is restricted, clear it with a “plumbers

snake” or similar probe device. Ensure that the auxiliary drain port

above the drain tube is also clear.

BLOWER

HOUSING

2 SETSCREWS

(HIDDEN)

C99085

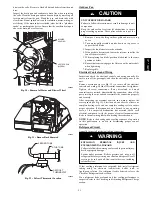

Fig. 20 -- Removal of Motor and Blower Wheel

A07680

Fig. 21 -- Burner Rack Removed

FEEDER TUBE

STUB TUBE

DEFROST

THERMOSTAT

C99029

Fig. 22 -- Defrost Thermostat Location

Outdoor Fan

UNIT OPERATION HAZARD

Failure to follow this caution may result in damage to unit

components.

Keep the outdoor fan free from all obstructions to ensure

proper cooling operation. Never place articles on top of the

unit.

CAUTION

!

1. Remove 6 screws holding outdoor grille and motor to top

cover.

2. Turn motor/grille assembly upside down on top cover to

expose the fan blade.

3. Inspect the fan blades for cracks or bends.

4. If fan needs to be removed, loosen the setscrew and slide the

fan off the motor shaft.

5. When replacing fan blade, position blade back to the same

position as before.

6. Ensure that setscrew engages the flat area on the motor shaft

when tightening.

7. Replace grille.

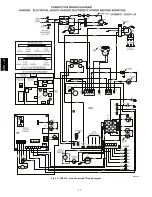

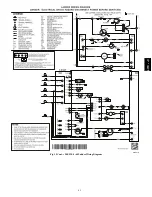

Electrical Controls and Wiring

Inspect and check the electrical controls and wiring annually. Be

sure to turn off the gas supply, and then the electrical power to the

unit.

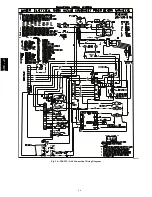

Remove access panels (see Fig. 19) to locate all the electrical

controls and wiring. Check all electrical connections for tightness.

Tighten all screw connections. If any discolored or burned

connections are noticed, disassemble the connection, clean all the

parts, re--strip the wire end and reassemble the connection properly

and securely.

After inspecting the electrical controls and wiring, replace the

access panels (see Fig. 19). Start the unit, and observe at least one

complete heating cycle and one complete cooling cycle to ensure

proper operation. If discrepancies are observed in any operating

cycle, or if a suspected malfunction has occurred, check each

electrical component with the proper electrical instrumentation.

Refer to the unit wiring label when making these checkouts.

NOTE

: Refer to the heating and/or cooling sequence of operation

in this publication as an aid in determining proper control

operation.

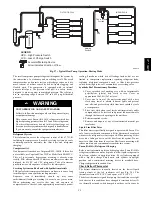

Refrigerant Circuit

Annually inspect all refrigerant tubing connections.

EXPLOSION,

PERSONAL

INJURY

AND

ENVIRONMENTAL HAZARD

Failure to follow this warning could result in personal injury,

death or property damage.

System under pressure. Relieve pressure and recover all

refrigerant before system repair or final unit disposal. Use all

service ports and open all flow--control devices, including

solenoid valves.

!

WARNING

If low cooling performance is suspected, leak--test all refrigerant

tubing using an electronic leak--detector, halide torch, or

liquid--soap solution. If a refrigerant leak is detected, refer to the

Check for Refrigerant Leaks section.

If no refrigerant leaks are found and low cooling performance is

suspected, refer to the Checking and Adjusting Refrigerant Charge

section.

677C

--

--

C

Summary of Contents for Legacy 677C**C Series

Page 3: ...3 A150538 Fig 2 24 30 Unit Dimensions 677C C...

Page 4: ...4 A150539 Fig 3 36 60 Unit Dimensions 677C C...

Page 44: ...44 A150506 Fig 15 208 230 1 60 Connection Wiring Diagram 677C C...

Page 45: ...45 A150516 Fig 15 Cont 208 230 1 60 Ladder Wiring Diagram 677C C...

Page 46: ...46 A150507 Fig 16 208 230 3 60 Connection Wiring Diagram 677C C...

Page 47: ...47 A150517 Fig 16 Cont 208 230 3 60 Ladder Wiring Diagram 677C C...