15

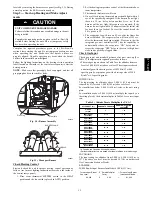

located by removing the burner access panel (see Fig. 19). During

normal operation, the LED is continuously on.

Step 3 — Start--up Heating and Make Adjust-

ments

UNIT COMPONENT DAMAGE HAZARD

Failure to follow this caution may result in damage to the unit

being installed.

Complete the required procedures given in the Pre--Start--Up

section before starting the unit. Do not jumper any safety

devices when operating the unit.

!

CAUTION

Complete the required procedures given in the Pre--Start--Up

section before starting the unit. Do not jumper any safety devices

when operating the unit. Make sure that burner orifices are

properly aligned. Unstable operation my occur when the burner

orifices in the manifold are misaligned.

Follow the lighting instructions on the heating section operation

label (located on the inside of the control access panel) to start the

heating section.

NOTE

: Make sure that gas supply has been purged, and that all

gas piping has been checked for leaks.

Pipe Plug

Manifold

A07679

Fig. 10 -- Burner Assembly

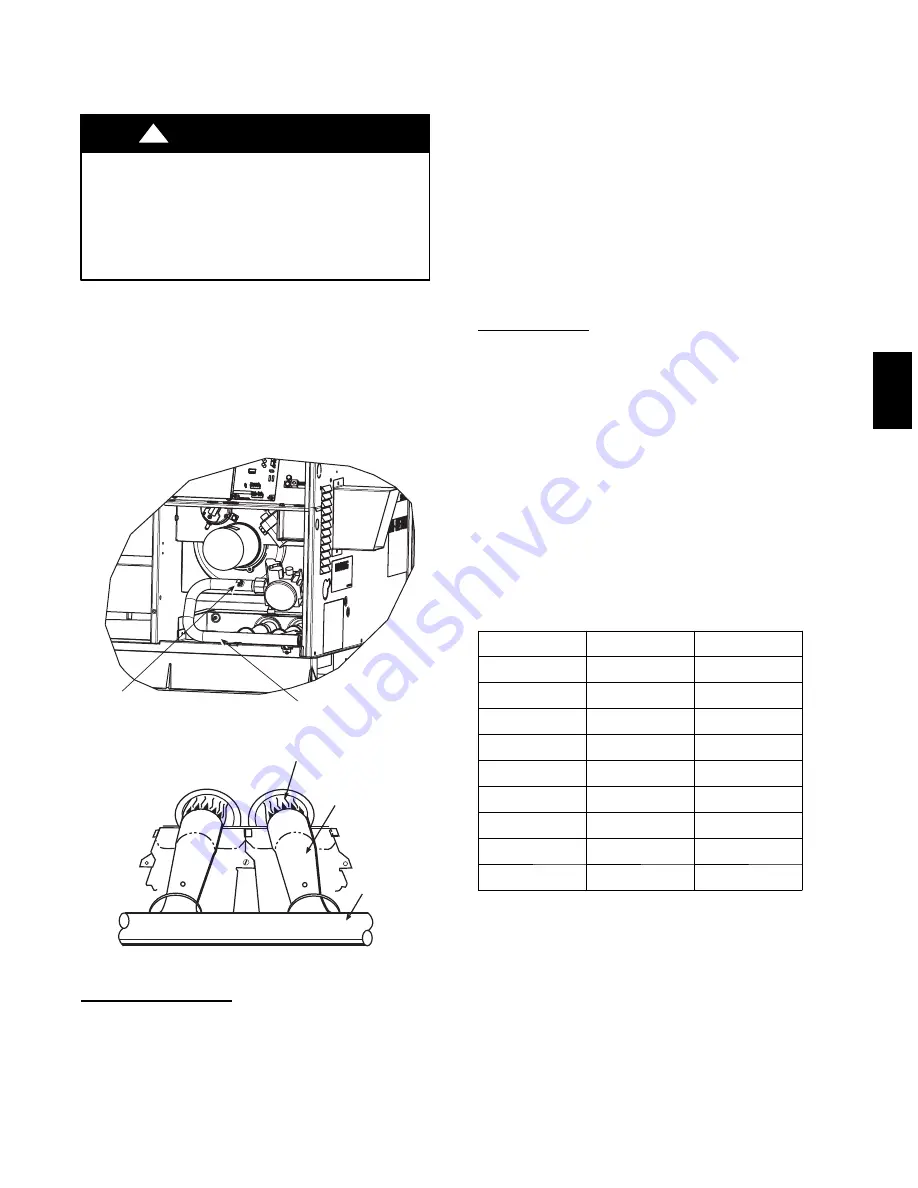

MANIFOLD

BURNER

BURNER FLAME

C99021

Fig. 11 -- Monoport Burner

Check Heating Control

Start and check the unit for proper heating control operation as

follows (see furnace lighting instructions located on the inside of

the control access panel):

1. Place room thermostat SYSTEM switch in the HEAT

position and the fan switch is placed in AUTO position.

2. Set the heating temperature control of the thermostat above

room temperature.

3. The induced--draft motor will start.

4. On a call for heating, the main burner should light within 5

sec. of the spark being energized. If the burners do not light,

there is a 22--sec. delay before another 5--sec. try. If the

burners still do not light, this sequence is repeated. If the

burners do not light within 15 minutes from the initial call

for heat, there is a lockout. To reset the control, break the

24--v power to W.

5. The evaporator fan will turn on 45 sec. after the flame has

been established. The evaporator fan will turn off 45 sec.

after the thermostat has been satisfied. Please note that the

integrated gas unit controller (IGC) has the capability to

automatically reduce the evaporator “ON” delay and in-

crease the evaporator “OFF” delay in the event of high duct

static and/or partially--clogged filter.

Check Gas Input

Check gas input and manifold pressure after unit start--up (See

Table 3). If adjustment is required proceed as follows:

S

The rated gas inputs shown in Table 3 are for altitudes from sea

level to 2000 ft (610 m) above sea level. These inputs are based

on natural gas with a heating value of 1025 Btu/ft

3

at 0.60

specific gravity, or propane gas with a heating value of 2500

Btu/ft

3

at 1.5 specific gravity.

IN THE U.S.A.:

The input rating for altitudes above 2,000 ft (610 m) must be

reduced by 4% for each 1,000 ft (305 m) above see level.

For installations below 2,000 ft (610 m), refer to the unit rating

plate.

For installations above 2,000 ft (610 m) multiply the input by on

the rating plate by the derate multiplier in Table 4 for correct input

rate.

Table 4 – Altitude Derate Multiplier for U.S.A.*

ALTITUDE FT (M)

PERCENT OF DERATE

DERATE MULTIPLIER

FACTOR

{

0---2000

(0---610)

0

1.00

2001---3000*

(610---914)

8--- 12

0.90

3001---4000

(315---1219)

12--- 16

0.86

4001---5000

(1220---1524)

16--- 20

0.82

5001---6000

(1524---1829)

20--- 24

0.78

6001---7000

(1829---2134)

24--- 28

0.74

7001---8000

(2134---2438)

28--- 32

0.70

8001---9000

(2439---2743)

32--- 36

0.66

9001---10,000

(2744---3048)

36--- 40

0.62

* In Canada see Canadian Altitude Adjustment.

{

Derate multiplier factors are based on midpoint altitude for altitude range.

IN CANADA:

The input rating for altitudes from 2,000 to 4,500 ft (610 m to

1372 m) above sea level must be derated 10% by an authorized

Gas Conversion Station or Dealer.

EXAMPLE:

90,000 Btu/hr Input Furnace Installed at 4300 ft (1311 m).

Furnace Input Rate at

Sea Level

X Derate Multiplier

Factor

= Furnace Input Rate at

Installation Altitude

90,000

X

0.90

=

81,000

677C

--

--

C

Summary of Contents for Legacy 677C**C Series

Page 3: ...3 A150538 Fig 2 24 30 Unit Dimensions 677C C...

Page 4: ...4 A150539 Fig 3 36 60 Unit Dimensions 677C C...

Page 44: ...44 A150506 Fig 15 208 230 1 60 Connection Wiring Diagram 677C C...

Page 45: ...45 A150516 Fig 15 Cont 208 230 1 60 Ladder Wiring Diagram 677C C...

Page 46: ...46 A150507 Fig 16 208 230 3 60 Connection Wiring Diagram 677C C...

Page 47: ...47 A150517 Fig 16 Cont 208 230 3 60 Ladder Wiring Diagram 677C C...