-34-

6.

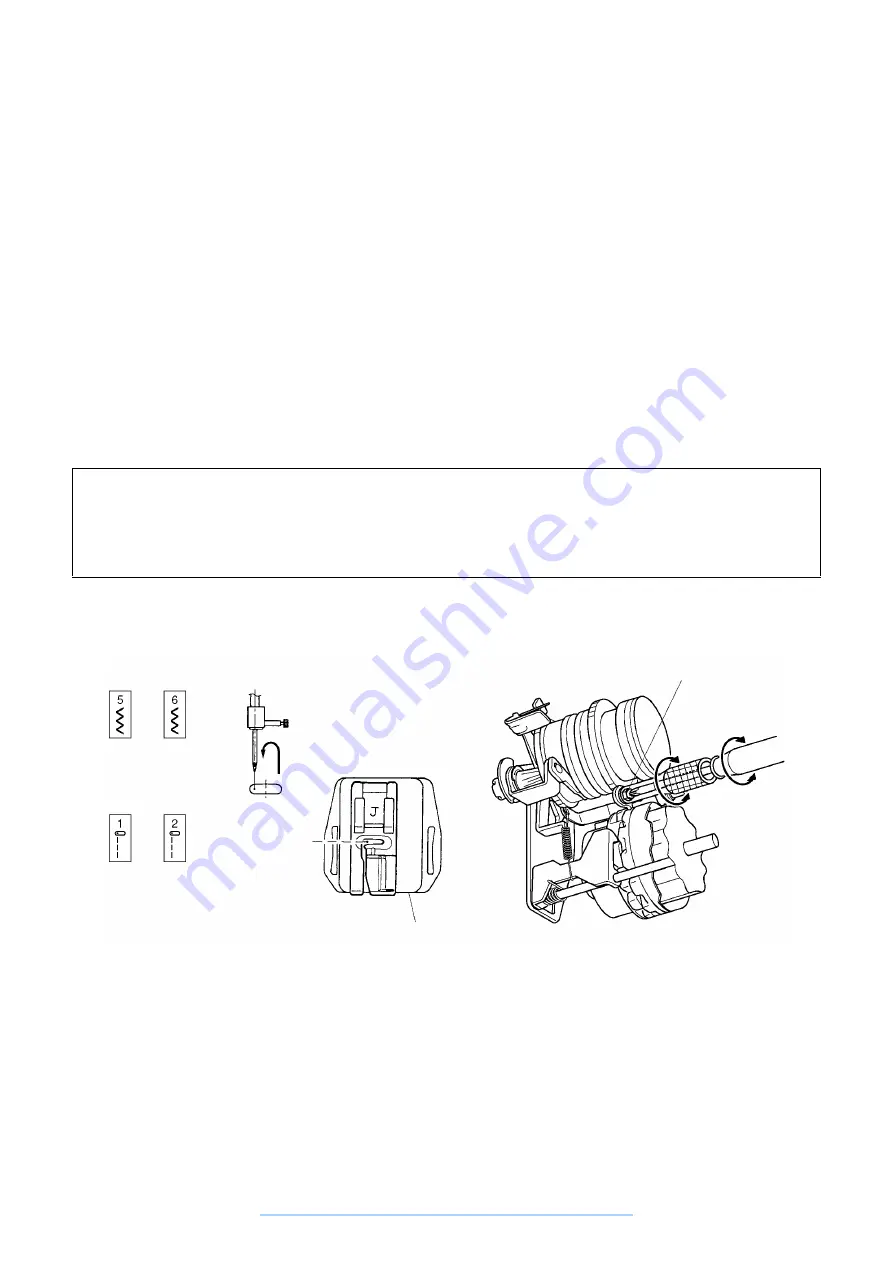

LEFT STRAIGHT LINE SEWING NEEDLE DESCENT AND THE ZIGZAG

MAXIMUM LEFT NEEDLE DESCENT ALIGNMENT

STANDARD

The left straight line sewing needle descent and zigzag maximum left needle descent should match.

ADJUSTMENT

1.

Put the feed dog cover on the needle plate and lay paper underneath the presser foot.

2.

Turn the selection dial, set to zigzag maximum sewing, and turn the balance wheel so that the needle falls

to the left.

3.

Turn the balance wheel and drill a small hole in the paper with the tip of the needle for left needle descent.

4.

Turn the selection dial and left straight line sewing.

5.

Loosen the screw securing the eccentric nut.

6.

Adjust the eccentric nut so that the tip of the needle comes to the position of the hole drilled in 3.

7.

Tighten the screw securing the eccentric nut.

Adjustment Points

6.

In left straight line sewing, when the eccentric nut is turned to the right, the needle descent moves to the

left.

7.

When fastening the eccentric nut with the screw, install the screw with the eccentric nut held in place with

a box driver so that the positioning is not lost.

Eccentric nut

Feed dog cover

XL-6060

XL-6050

XL-6040

XL-6060

XL-6050

XL-6040

www.promelectroavtomat.ru

Summary of Contents for XL-6040

Page 1: ... 6 2001 www promelectroavtomat ru ...

Page 3: ... 1 I 1 MECHANICAL CHART 2 2 POWER TRANSMISSION CHART 3 www promelectroavtomat ru ...

Page 4: ... 2 1 MECHANICAL CHART www promelectroavtomat ru ...

Page 29: ... 27 2 LEAD WIRES ARRANGEMENT www promelectroavtomat ru ...

Page 61: ...XL 6060 Series XL 6050 Series XL 6040 Series H1040194 www promelectroavtomat ru ...