-41-

13.

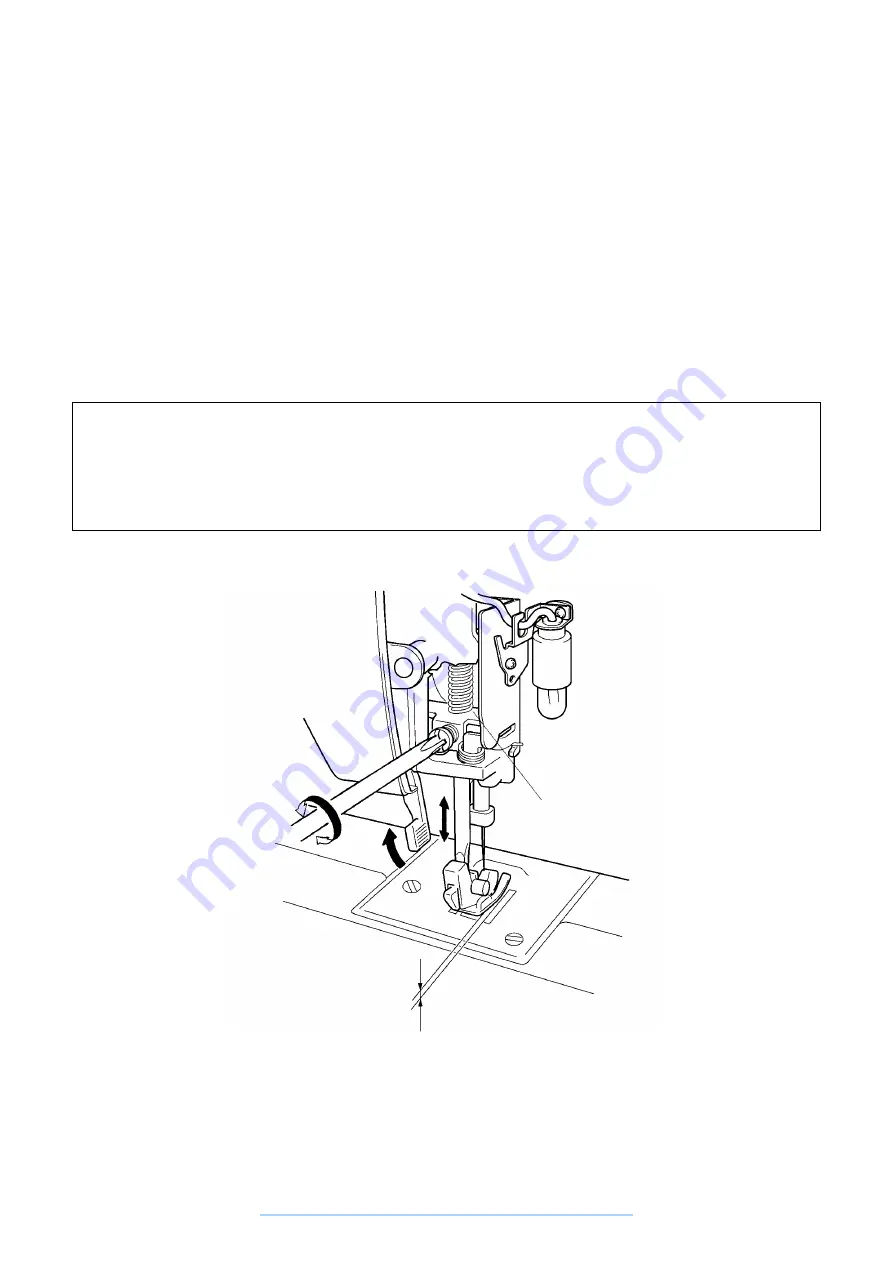

PRESSER BAR HEIGHT

STANDARD

The height of the presser bar should be such that when the presser lifter is raised (1st-stage lift state), the

distance from the top surface of the needle plate to the bottom surface of the presser foot should be 6.0-6.5 mm.

ADJUSTMENT

1.

Raise the presser lifter.

2.

Loosen the screw securing the presser bar clamp.

3.

Move the presser bar up and down and adjust so that the distance between the top surface of the needle

plate and the bottom surface of the presser foot is 6.0-6.5 mm.

4.

Tighten the screw securing the presser bar clamp.

Adjustment Point

3.

Check that the side surface of the presser foot and the needle plate feed dog groove are parallel. If the

presser foot is not parallel, the needle may strike the presser foot or the fabric may not feed straight while

overcasting.

Adjust the presser bar height with the feed dog below the needle plate top surface.

*

Install presser foot J.

Presser bar clamp

6.0-6.5 mm

www.promelectroavtomat.ru

Summary of Contents for XL-6040

Page 1: ... 6 2001 www promelectroavtomat ru ...

Page 3: ... 1 I 1 MECHANICAL CHART 2 2 POWER TRANSMISSION CHART 3 www promelectroavtomat ru ...

Page 4: ... 2 1 MECHANICAL CHART www promelectroavtomat ru ...

Page 29: ... 27 2 LEAD WIRES ARRANGEMENT www promelectroavtomat ru ...

Page 61: ...XL 6060 Series XL 6050 Series XL 6040 Series H1040194 www promelectroavtomat ru ...