-24-

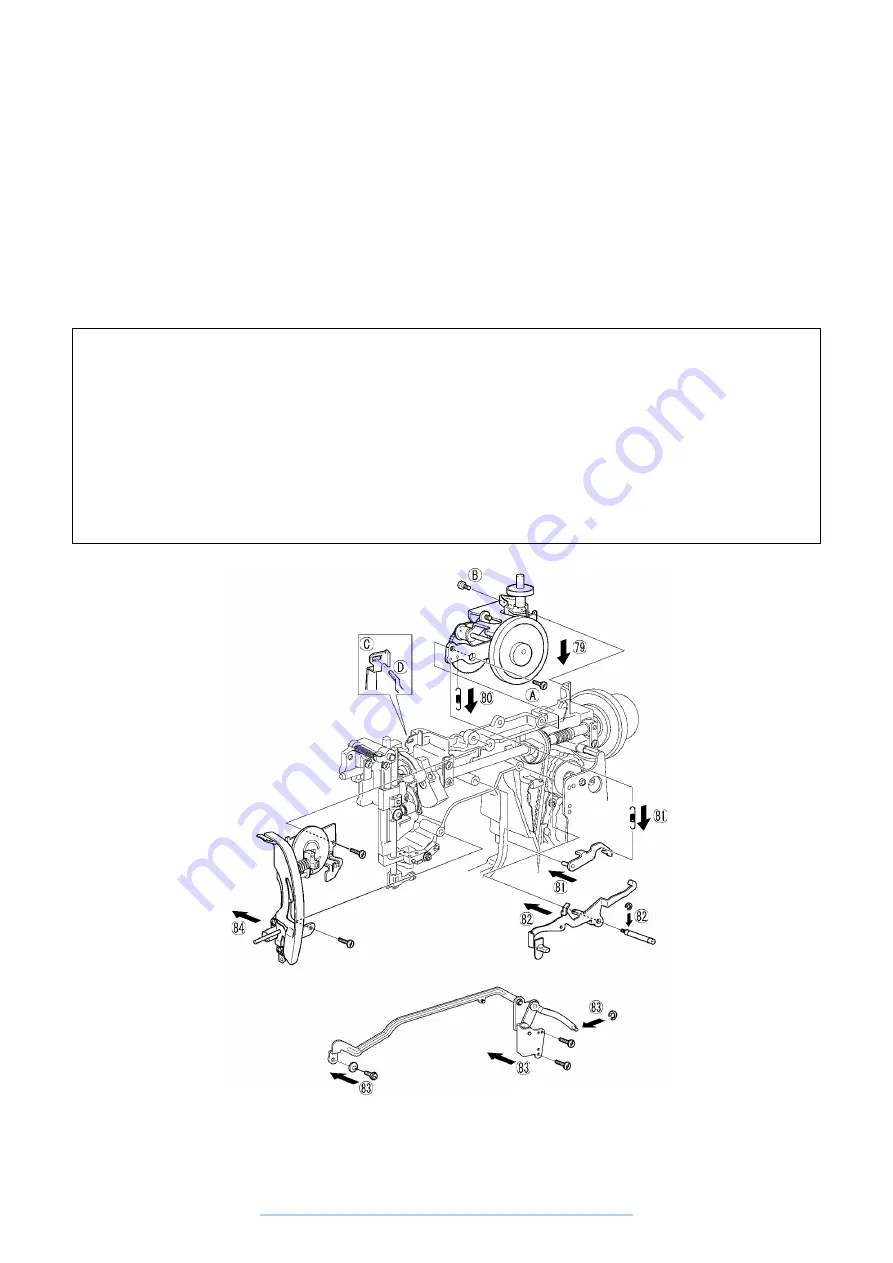

79. Align the feed bracket assembly fear section and install with the two tightening screws. (See Adjustment

Procedure 18.)

80. Hang the feed regulator tension spring on the feed bracket assembly and feed regulator.

81. Install reverse sewing lever B on the arm and hang the tension spring on the reverse sewing lever B and

feed bracket assembly.

82. Install reverse sewing lever A with the screw and lock ring.

83. Install the Zigzag connecting rod assembly on the selection unit with the lock ring, tighten with the two

screws, install on the needle bar block with the Zigzag adjustment nut and tightening screw and hang the

feed rod tension spring.

84. Install the thread tension connecting rod assembly with the two screws.

Assembly Points

79. Install the feed bracket assembly screws in the order (A), then (B). After installing the feed bracket

assembly, be careful about backlash at the feed bracket assembly gear. (See Adjustment Procedure 18.)

80. Hang the feed regulator tension spring with the shorter hook section on the feed bracket assembly.

83. Hang the feed regulator tension spring with the longer hook section on the feed bracket assembly.

83. Install the Zigzag adjustment nut with the hex nut section facing up.

84. When installing the thread tension assembly, lower the presser lifter and pass the thread tension

assembly thread slack plate B tip D through the (C) hole in thread slack plate C. After installing the thread

tension assembly, raise and lower the presser lifter and check that the thread tension adjuster plate opens

and closes.

www.promelectroavtomat.ru

Summary of Contents for XL-6040

Page 1: ... 6 2001 www promelectroavtomat ru ...

Page 3: ... 1 I 1 MECHANICAL CHART 2 2 POWER TRANSMISSION CHART 3 www promelectroavtomat ru ...

Page 4: ... 2 1 MECHANICAL CHART www promelectroavtomat ru ...

Page 29: ... 27 2 LEAD WIRES ARRANGEMENT www promelectroavtomat ru ...

Page 61: ...XL 6060 Series XL 6050 Series XL 6040 Series H1040194 www promelectroavtomat ru ...