IV - 3

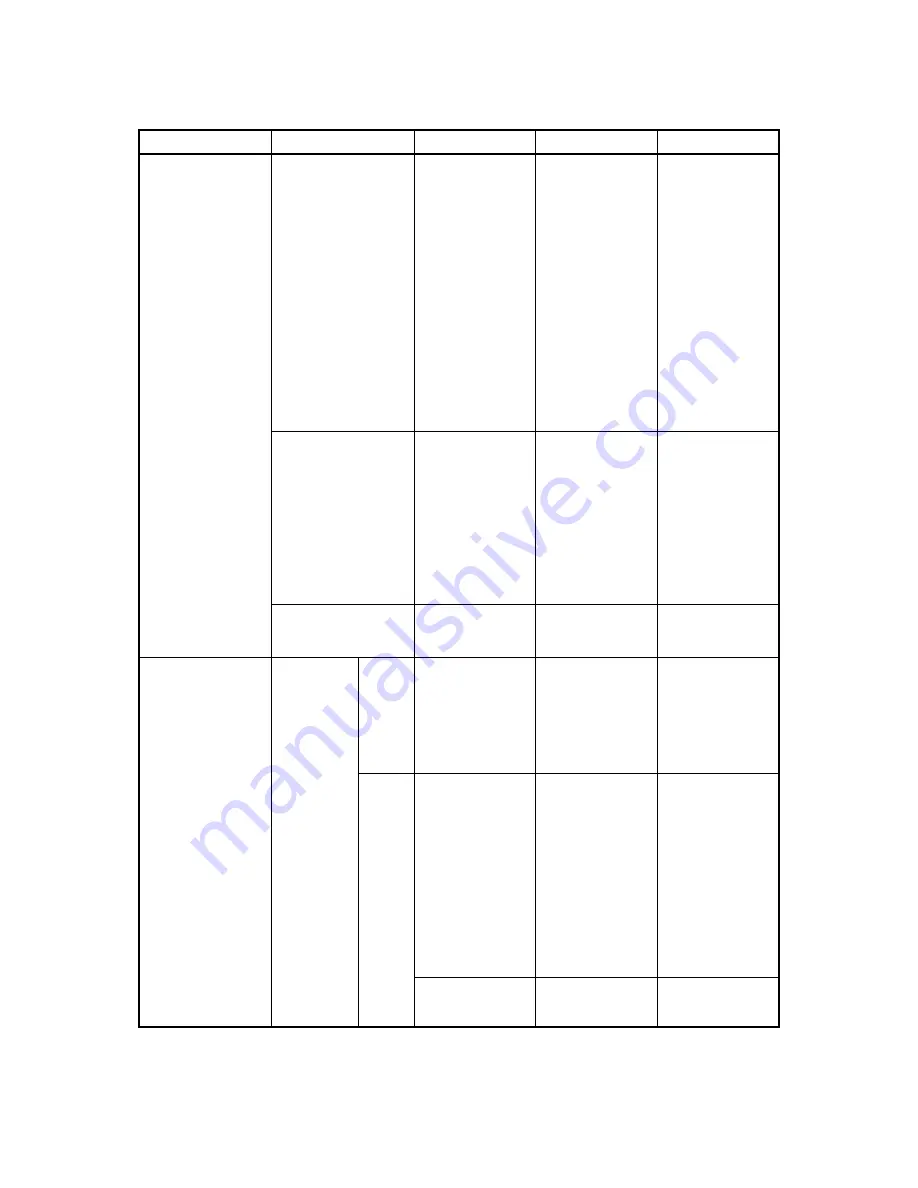

Error mode

Checking method

Cause

Action

Service manual

The motor rotates,

but a draft sheet or

an ID label is not

fed correctly.

Is the clutch spring on

the paper feed roller

deformed or broken?

Deformed or

broken clutch

spring

Replace the

deformed or

broken clutch

spring.

CHAPTER III

1.15

Disassembly of

the Gears and

Pulleys

1.17

Disassembly of

the Rollers

2.4

Reassembly of

the Rollers

2.6

Reassembly of

the Gears and

Pulleys

Is the timing belt

(MXL belt) cut?

Broken timing belt

(MXL belt)

Replace the

broken timing belt

(MXL belt).

CHAPTER III

1.15

Disassembly of

the Gears and

Pulleys

2.6

Reassembly of

the Gears and

Pulleys

Non of the above

Defective sensor

or PCB

→

Electronic part

The paper feed

motor or the main

motor does not

rotate, preventing a

draft sheet or an ID

label from being

fed.

Is the

connector

of the paper

feed motor

or the main

motor dis-

connected?

YES

Disconnected

connector of the

motor

Connect the

disconnected

connector of the

motor.

CHAPTER III

2.17

Reassembly of

the Main PCB

Assy

NO

Defective motor

Replace the

defective motor.

CHAPTER III

1.16

Disassembly of

the Motor

Holder Assy

and the Motors

2.5

Reassembly of

the Motor

Holder Assy

and the Motors

Defective PCB

→

Electronic part

Summary of Contents for SC-2000

Page 1: ...Stamp Creator PRO SERVICE MANUAL MODEL SC 2000 Version A ...

Page 2: ...Stamp Creator PRO SERVICE MANUAL MODEL SC 2000 ...

Page 13: ...I 7 Fig 1 6 ID Label 1438 Fig 1 7 ID Label 1850 Fig 1 8 ID Label 2770 ...

Page 118: ...II 4 Fig 2 2 Block Diagram of the Electronic Part ...

Page 132: ...III 14 Fig 3 15 Stamp Size Detection Open Cover Detection and Key Scanning Circuit ...

Page 138: ...III 20 Fig 3 21 Control Panel PCB Circuit ...

Page 144: ...APP 1 ...

Page 145: ...APP 2 ...

Page 146: ...APP 3 ...

Page 147: ...APP 4 D 100V AC System Power Supply Circuit ...

Page 148: ...APP 5 E 200V AC System Power Supply Circuit ...

Page 149: ...APP 6 ...

Page 150: ...Sep 98 5V5014BE0 Printed in Japan ...