12. TABLE OF ERROR CODES

169

KE-430HX/KE-430HS, BE-438HX/BE-438HS

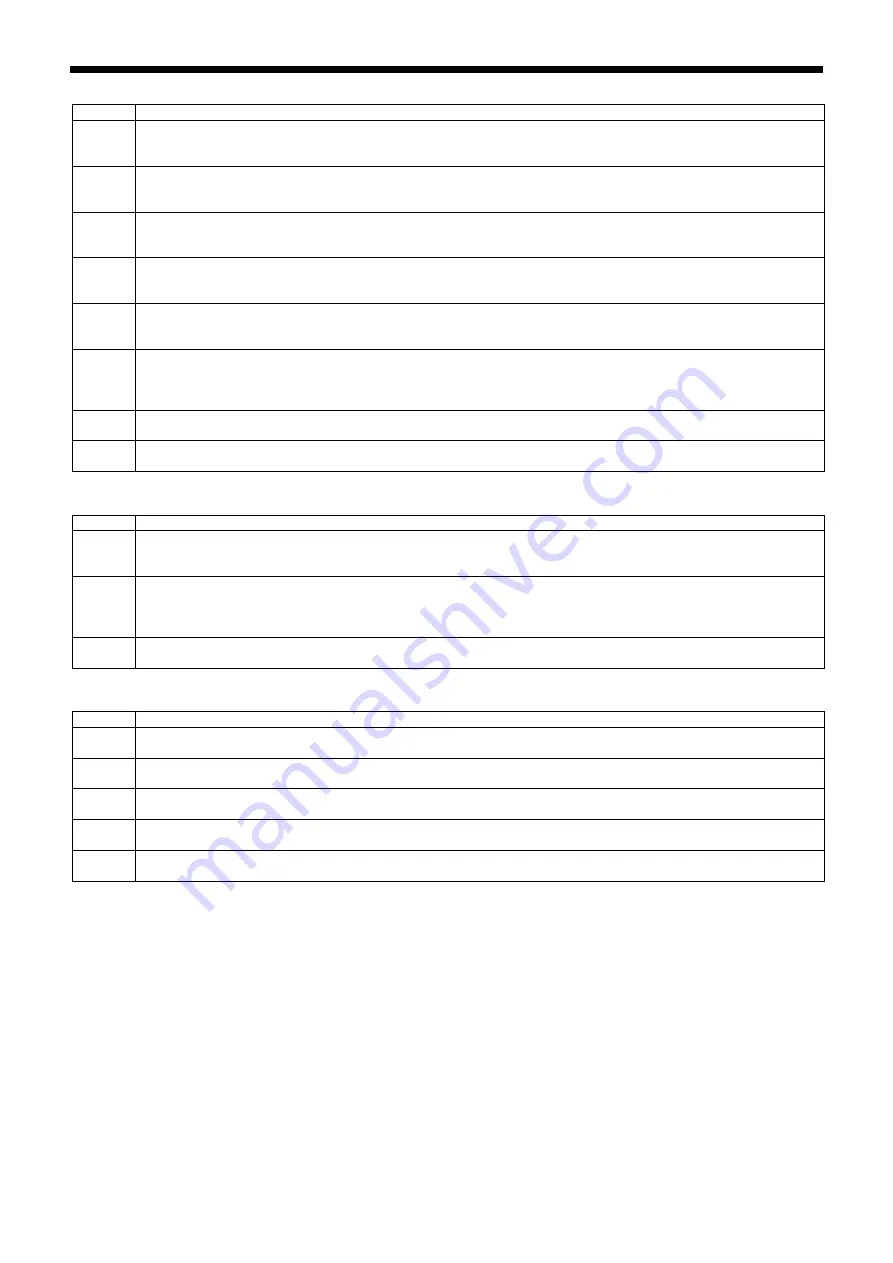

Data editing-related errors

Code

Cause and remedy

E500

The enlargement ratio setting caused the sewing data to extend outside the sewing area.

Press the reset key to clear the error.

Set the enlargement ratio again.

E502

The enlargement ratio caused the stitch length to exceed the maximum length of 12.7 mm.

Press the reset key to clear the error.

Set the enlargement ratio again.

E510

Error in pattern data.

Press the reset key to clear the error.

Re-read the pattern data from the USB memory, or recreate the pattern data.

E511

No end code has been input into pattern data.

Press the reset key to clear the error.

Recreate the pattern data containing the end code, or change the pattern number being read.

E512

Number of stitches exceeds allowed maximum.

Press the reset key to clear the error.

Change the number of the pattern being read.

E581

Memory switch file cannot be read correctly.

Copy source model and copy destination model are incorrect. (Maybe the 430HX/HS is attempting to read data for

the 438HX/HS.)

Read data for the same sewing machine model.

E582

Memory switch versions do not match.

Read data for the same version.

E583

Parameter versions do not match.

Read data for the same version.

Device-related errors

Code

Cause and remedy

E600

Upper thread breakage has occurred.

Thread the upper thread and then press the reset key to clear the error.

Re-sewing is then possible.

E690

Thread trimmer pulse motor home position cannot be detected. Problem with thread trimmer pulse motor or poor

thread nipper encoder connection.

Turn off the power, and then clean underneath the needle plate to remove any dust and thread scraps.

Check that connector on the main P.C. board is properly connected.

E692

Thread trimmer pulse motor stopped abnormally.

Turn off the power, and then check.

P.C. board-related errors

Code

Cause and remedy

E700

Abnormal rise in power supply voltage.

Turn off the power and check the input voltage.

E701

Abnormal rise in main shaft motor drive voltage.

Turn off the power, and then check the voltage.

E705

Abnormal drop in power supply voltage.

Turn off the power and check the input voltage.

E710

Abnormal current was detected in main shaft motor.

Turn off the power, and then check if there are any problems with the sewing machine.

E711

Abnormal current was detected in pulse motor.

Turn off the power, and then check if there are any problems with each motor.

Summary of Contents for BE-438HS

Page 203: ...14 ELECTRIC MECHANISM 192 KE 430HX KE 430HS BE 438HX BE 438HS 4313B ...

Page 204: ...14 ELECTRIC MECHANISM 193 KE 430HX KE 430HS BE 438HX BE 438HS 4314B ...

Page 205: ...14 ELECTRIC MECHANISM 194 KE 430HX KE 430HS BE 438HX BE 438HS 4315B ...

Page 206: ...14 ELECTRIC MECHANISM 195 KE 430HX KE 430HS BE 438HX BE 438HS 4316B ...