37

Treadwall M6 Pro Owner’s Manual—2017

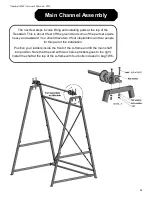

Main Channel Assembly

Install the angle-adjuster tube through the holes

with plastic bushings in the channels.

The wheel is usually located on the right side of

the Treadwall, but it can be on either side,

depending on the location. Make sure there is

good access to it. All of the hardware for the

angle adjuster is located in bag M6-3

After the cables are installed and working, move

the assembled Treadwall to its final location

while it is still light enough to push around. If it is

on a finished floor, slip rags or hand towels

under the feet to prevent scratching.

When you first uncoil the cables, you will see that there is a kink in the

cable. The cables are attached to the tube by hooking this kink under a

tab cut into the tube near each end (fig. 1). Note that the kink is not in

the middle of the cable. There is a long end and a short end.

Attach the cable to the tube (by hooking the kink under the triangular

tab) with the short end going towards the back. After you wind the

cable, this end will actually be going towards the front of the machine.

fig. 1

Lock the tube from rotating by pushing one hole of the

locking disk onto the stud on the channel. Wind the short

end of the cable onto the tube in neat coils in a clockwise

direction. Note in fig. 2 how the cable is wound so that the

short end is near the outside end of the tube.

This is the

right side of the Treadwall. On the left side, the cable is

wound so that the short end is on the inside (fig.5).

After about five coils, attach the cable to the front of the

frame ( fig. 3).

fig. 2

fig. 3

Summary of Contents for Treadwall M6 Pro

Page 2: ......

Page 4: ...ii Treadwall M6 Pro Owner s Manual 2017...

Page 6: ...2 Treadwall M6 Pro Owner s Manual 2017...

Page 8: ...4 Treadwall M6 Pro Owner s Manual 2017...

Page 14: ...10 Treadwall M6 Pro Owner s Manual 2017...

Page 16: ...12 Treadwall M6 Pro Owner s Manual 2017...

Page 50: ...46 Treadwall M6 Pro Owner s Manual 2017...