Install “Physical Gate Stops

Physical gate stops MUST be installed at each end of your gate. If the

magnetic switch on the motor fails to stop the gate cycle, the gate stops will

prevent the gate from falling off the guide rollers and causing possible injury or

damage.

Installing Motor

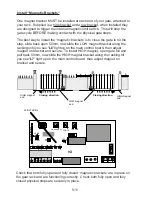

Preparation of the concrete ground surface (base) for motor mounting

Make sure that the ground surface for the motor installation is solid and level.

A good base is paramount to the proper operation of the gate opener

system. If installing cables, place these 300mm from your wall/post and

approx. 220mm in from the corner of the wall/post. The motor mounting plate

is 170mm deep x 270mm wide. Position the motor mounting plate (

side nearest to the gate) approx. 150-160mm from the wall/post and approx.

50mm in from the post driveway corner point.

Post

Gate

Motor

50mm

170mm

270mm

60mm

Top View Base Footprint

Cables from the control panel to the motor can be

per-embedded

in the base

should concealed wiring be preferred. Check with you

r

electrician. You may

have to space the bottom of the base plate with spacers to gain some height

to run wires and cables. Again check with your electrician.

Prepare for motor cable. Optional

devices

such as wired keypad, photo

beams etc. use telecom cable, cat-5 or cat-6

2/1

1