1.

Remote control single three key functions.

2.

Half-open function (non standard).

3.

Automatic closing function.

4.Soft stop function.

5.Full power to start.

6.

Programmable State.

K3

L1

L2

L3

L4

L5

L6

L7

LED9

LED8

F

FORCE

TORQUE

MOTOR

N

L

AC220V

L1

COM

L2

+15V COM FSW ONE STP CL OP

C.L COM O.P

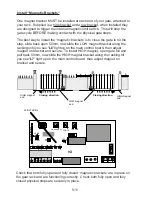

Wiring diagram

wireless receiver

Rebound resistance function,turn to max. force (clockwise)

to cancel this function.

ON

Function key

Learning key

Motor direction

Limit swicth

Adjust motor's thrust after the gate is installed.

(clockwise is bigger)

Limist switch input terminal(Closing direction)

Common terminal

Limist switch input terminal(Open direction)

15

V

10

0m

A

ma

x.

Power output

Common terminal

Infrared safety electric eye (Closing direction) input terminal

A single key circulation

Stop

input

Close input

Open input

Motor phase line

Motor common line

Motor phase line

220V AV 60W flashing lamp output.

220V Power supply

(null line)

220V Power supply

(live line)

SLOW THRUST

Adjust motor's power.(clockwise is bigger)

1

1

/1

1

I

---

Light

11

12

13

14 15

16

17 18

Earth

IMPORTANT

240 Volt power supply must be safely secured inside

the motor housing to prevent the power supply from

being disconnected from the main board. If not

secured correctly this may cause the LW550 to

become an electrical hazard.