- 10 -

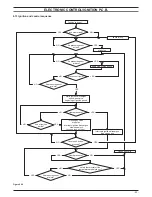

FAult Finding

7

C

omp

on

en

ts

to

ch

ec

k

S

ec

tio

n

of

the

m

anual

!

(n

ot

e

ref

.i

n

brac

ket

s)

---

---

--- (8)

--- (7)

17

.1

16

.2

15

.2

14

.2

13

12

.2

10

.2

9.4

8.10

7.2

--- (4)

18

.1

--- (3)

--- (2)

--- (1)

Loc

k---

out

sig

nal

lam

pre

d

Pres

sur

eg

aug

e

Saf

ety

val

ve

Exp

ans

ion

vesse

l

Inje

ctor

s

Flue

prob

eN

TC

Saf

ety

the

rm

ost

at

Det

ect

ion

ele

ctro

de

Ign

itio

nel

ectrod

e

Air

pre

ssure

senso

r

Fan

By---

pas

sv

alv

e

Main

circu

itte

mp.p

rob

e

Main

circu

itf

low

switch

Gas

val

ve(m

odul

atin

go

perat

or)

Gas

val

ve(o

n---

off

ope

rators

)

Boil

erse

ttings

Ele

ctro

nic

p.c.

b.

Fus

es(E

lec

tro

nic

p.c

.b.)

Pump

C.h

.cir

cuit

Conde

nsat

edr

ain

pip

ea

ndtr

ap

Flue

pipe

s

Gas

sup

ply

line

Pow

ers

upp

lyli

ne

De

fe

ct

#

O

n

c/

h

m

od

e

th

e

te

m

pe

ra

tu

re

of

th

e

ma

in

cir

cu

it

re

ach

es

75

C

an

d

th

e

c/h

sy

st

em

do

es

no

th

eat

.

J

In

co

rr

ec

tm

od

ul

at

io

n

J

J

J

N

oisy

bolie

r

J

J

OFF

Th

e

bo

ile

ro

pe

rat

es

co

rrec

tly

bu

tt

he

gas

pr

es

su

re

to

th

e

bur

ne

rr

em

ai

ns

at

m

in

im

um

.

J

J

---

W

at

er

le

ak

s

fro

m

th

e

saf

et

y

val

ve

du

r-

in

g

op

er

ation

on

c/

h

J

J

J

J

---

W

at

er

le

ak

s

fro

m

th

e

saf

et

y

val

ve

w

he

n

th

e

bo

ile

ris

of

f.

J

J

J

N

ote

U

se

fu

lin

fo

rm

at

io

n

ca

n

be

ob

ta

in

ed

al

so

fr

om

the

op

tic

al

in

dic

at

io

n

give

n

by

the

ap

pl

ia

nc

e

op

er

-

at

io

n

lig

hts

(s

ee

se

ctio

n

8.

4)

.

1

C

he

ck

fo

r230V~

between

lin

e

(L

)a

nd

ne

ut

ra

l(N

)

Ve

rif

y

th

e

in

te

gr

ity

of

su

pp

ly

ca

bl

e,

pl

ug

an

d

ex

te

rn

al

fu

se

s.

C

he

ck

the

po

la

rit

y

of

line

and

ne

ut

ral

co

nne

ct

io

n

2

Ve

rif

y

th

e

tig

htn

es

s

of

th

e

ga

s

su

pp

ly

pip

e,

th

e

position

of

st

op

val

ve

s.

C

he

ck

the

gas

pr

es

su

re

at

th

e

inl

et

te

st

po

in

to

ft

he

gas

val

ve

(s

ee

se

ct.

9.

3)

w

ith

th

e

bo

ile

ra

tr

est

an

d

du

rin

g

op

er

ation

an

d

co

mp

ar

e

it

w

ith

th

e

va

lu

es

gi

ve

n

on

th

e

in

st

alla

tio

n

bo

ok

le

t.

3

C

he

ck

fo

rs

ou

nd

ne

ss

an

d

ab

se

nc

e

of

ob

st

ru

ct

io

ns

.V

er

ify

th

at

th

e

flu

e

te

rmin

al

is

co

rr

ect

ly

in

st

alle

d

(se

e

cle

ar

an

ce

s)

an

d

en

-

su

re

th

at

exhaus

tg

as

is

no

ts

uc

ke

d

bac

k

by

the

bo

ile

r.

4

C

he

ck

fo

rs

ou

nd

ne

ss

of

th

e

ci

rc

ui

ta

nd

ve

rify

its

co

rr

ec

tf

ill

in

g

(s

ee

al

so

in

st

alla

tio

n

ma

nu

al)

.

5

A

ja

m

m

ed

by

---

pa

ss

co

ul

d

ca

us

e

th

e

ov

er

---

he

at

in

g

of

th

e

m

ai

n

ci

rc

ui

ta

nd

th

e

in

te

rv

en

tio

n

of

th

e

sa

fe

ty

th

er

m

os

ta

t.

6

C

he

ck

the

min

imu

m

ga

s

pre

ss

ure

at

th

e

ou

tle

tt

es

tp

oi

nt

of

th

e

ga

s

va

lv

e

(s

ee

se

ct.

9.

3)

an

d

comp

ar

e

it

w

ith

th

e

va

lu

e

giv

en

on

th

e

in

sta

lla

tion

book

le

t.

7

Ve

rif

y

th

e

cl

ea

nn

es

s

of

in

je

ct

or

s.

8

C

he

ck

th

e

pr

essu

riz

atio

n

of

th

e

ex

pa

nsio

n

ve

sse

l.

R

ef

er

to

th

e

in

st

al

la

tion

ma

nu

al

for

pr

op

er

va

lu

es

.