SW-Stahl und Werkzeugvertriebs GmbH

Tel. +49 (0) 2191 / 46438-0

F

5 6

e s s a r t S r e s u k r e v e L

ax +49 (0) 2191 / 46438-40

e d . l h a t s w s

@

o f n i : l i a

M - E

d i e h c s

m

e R 7 9 8 2 4 - D

Instruction Manual

BGS technic KG

Bandwirkerstr. 3

D-42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

www.bgstechnic.com

TOOLS

This tool set includes also the following components:

•

3 different sliding hammers 1.6 kg x 160 mm / 2.7 kg x 460 mm / 5.1 kg x 600 mm

•

Pulling claws with fork opening 13.7 x 18 mm, length 105 mm and 12.7 x 19 mm, length 130 mm

•

Slotted 6-point sockets, 12.5 mm (1/2”), length 100 mm, sizes 25 - 27 - 28 - 29 - 30 mm

•

Injector extractor, sleeve type with supporting shell, outer diameter 35 mm,

inner diameter 29 mm, spindle thread M17 x 1.0

•

Pulling adapter with external thread, M27 x 1.0 (3 pcs) and M25 x 1.0

•

Pulling adapter with internal thread, M27 x 1.0 (3 pcs)

•

Sliding hammer adapter for inner, outer and claw extractor

DESCRIPTION

Adaptor

Sockets

Internal Hexagon

NOTE:

The technique required for removal of the injector will depend on which system is fitted to the

vehicle. Always use an external adaptor first if possible. If by using reasonable force the in je ct or cannot

be removed, use an internal adaptor. Before working on the fuel system, make sure that the fuel system is

not under pressure. Refer to the manufacturer's instruction manual on how to de-pressurise the system.

Disconnect the injector wires and connections as per the manufacturer's instructions. Remove any carbon

build up from around the injector. Remove the electrical unit from the injector.

OPERATION

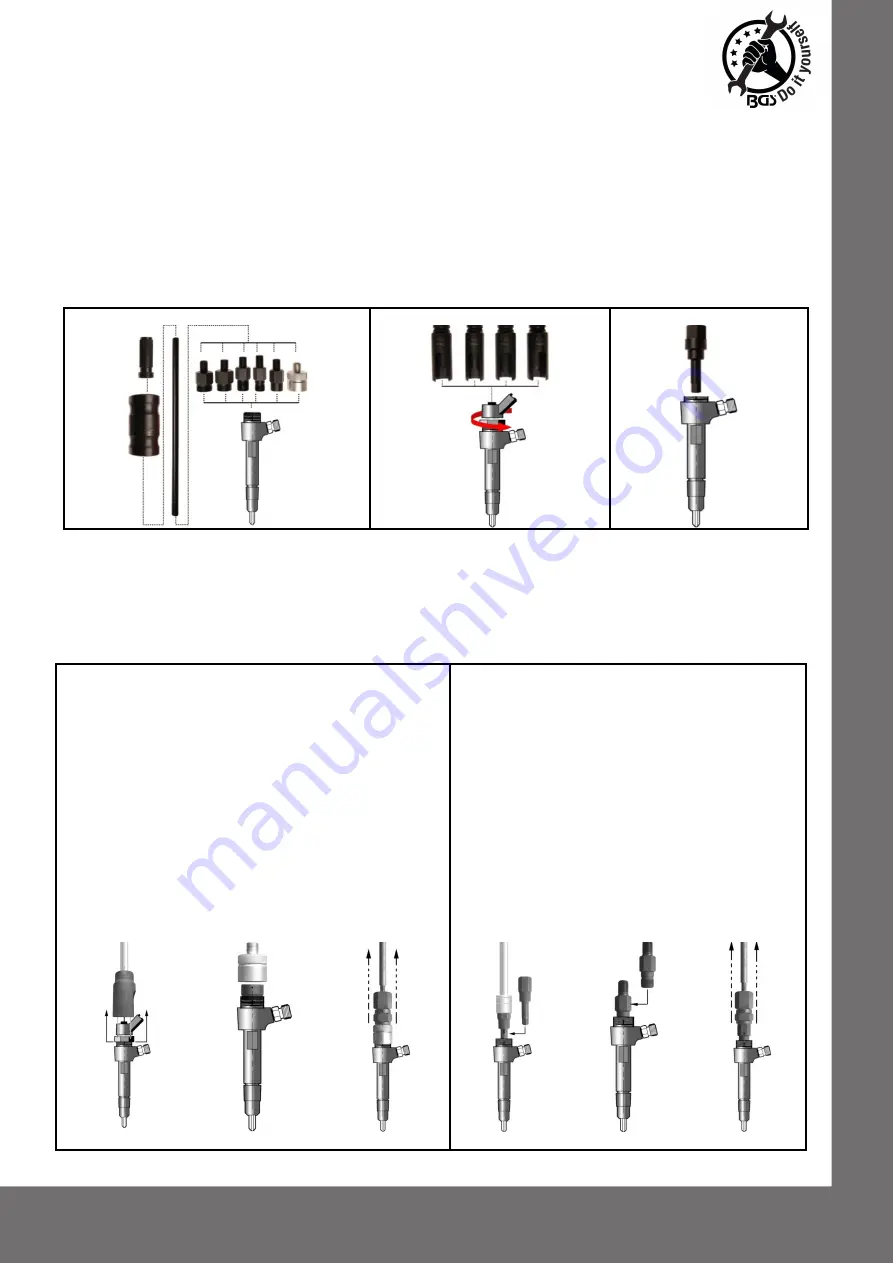

External Thread Adaptor

Internal Thread Adaptor

1. Remove the electrical unit (see A).

2. Position the adapter with outside thread on top of

the injector (see B)

3. Connect sliding hammer to the adapter with

outside thread (see C).

4. The injector can be removed by using reasonable

force on the sliding hammer.

5. When an injector has been removed, it is

recommended that only a new or refurbished

injector is fitted.

6. Follow manufacturers fitting and safety

instructions.

1. Remove the electrical unit (see A).

2. Insert and turn anti-clockwise a special hex

socket to remove the inner sleeve (see D).

3. Screw the appropriate internal adaptor (5)

into the threads of the injector and tighten

with a suitable spanner (see E).

4. Screw the slide hammer onto the adaptor.

5. The injector can now be removed using

reasonable force on the slide hammer (see

F). Be prepared for the sudden release of

the injector from the cylinder head.

6. When an injector has been removed, it is

recommended that only a new or

refurbished injector is fitted.

7. Follow manufacturers fitting and safety

instructions.

A

B

C

D

E

F

NOTE:

To protect the threads, all fittings must be tightened.