14 -

LEM7 LEM8F Ver. 01

D811025A_01

INSTALLATION MANUAL

ENGLISH

WARNING:

If the opening direction is not correct, invert the motor

connections no. 3 and 5 and connections no. 11 and 12 of the opening and

closing limit switches.

13) MOTOR TORQUE SETTING (SAFETY CLUTCH)

WARNING: Check that the impact force value measured at the

points established by the EN 12445 standard is lower than that

specified in the EN 12453 standard.

The setting must be carried out according to whatever is provided for by the

current safety standards. For this purpose, the motor torque needs to be set

in the following way:

•

Disconnect the mains power supply.

•

Remove the screws securing the gearmotor guard.

•

Use the fixed key provided to lock the motor shaft (fig.17 - ref. “A”). Using

the release knob, screw the self-locking nut (fig.17 - ref. “D”) to increase

the torque, or slacken it to decrease the torque.

•

Reconnect the power supply and, with the help of a torquemeter, check

that the motion stops at the mechanical resistance values set out by the

current standards.

•

Put the protection guard back on the gearmotor and secure it with its

screws.

DANGER - The torque regulator must be calibrated before the

automation system is made to be operational.

14) EMERGENCY MANOEUVRE

Manual leaf opening is to be carried out in case of power supply failure or

automation inefficiency. Two types of knobs are available:

A) Pull-out knob

B) Personalised key-knob

Knob “A”

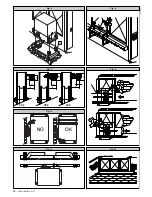

(fig.18)

•

Insert the release knob in the appropriate seat, and rotate it clockwise

along its entire travel.

•

Push the gate leaf by hand.

•

In order to reset motor-driven operation or keep the gate locked on closing,

rotate the knob anticlockwise along its entire travel, move the leaf by hand

until it reaches its dragging point, remove the knob and keep it in a place

known to all users.

•

When the power supply comes back on, the automation device will resume

motor-driven operation.

Knob “B”

(fig. 19-20)

In the case where a locking knob with a personalised key (fig.19-20) is used,

proceed as follows:

•

Insert the personalised key (fig.19) in knob lock, and rotate the knob

anticlockwise until a click is heard.

•

Rotate the release key clockwise along its entire travel (fig.20).

•

Push the leaf by hand. The personalised key cannot be pulled out until

motor-driven operation is reset.

•

In order to reset motor-driven operation, rotate the knob anticlockwise,

and rotate the key clockwise until it comes out.

•

Keep the key in a place known to all users.

15) INSTALLATION CHECK

Before the automation device finally becomes operational, scrupulously

check the following conditions:

•

Check that all the safety devices (limit microswitches, photocells, electric

edges etc) operate correctly.

•

Check that the rack and pinion are correctly meshed (minimum play 2mm).

•

Check that the pushing force of the gate is within the limits provided for by

the current standards.

•

Check that the opening and closing end-of-stroke runners are correctly

positioned and tightly secured.

•

Check the starting and stopping operations using the manual control.

•

Check the starting and stopping operations using the remote radio control.

•

Check the normal or customised operation logic.

16) AUTOMATION DEVICE USE

Since the automation device can be controlled both remotely and in sight,

by means of a radio control device or a button, all the safety devices must

be frequently checked in order to ensure their perfect efficiency.

WARNING! In the event of any safety device malfunction, request

immediate assistance from qualified personnel. Children must be

kept at a safe distance from the automation operation area.

17) AUTOMATION CONTROL

The use of this control device allows the gate to be opened and closed

automatically. There are different types of controls (manual, radio control,

magnetic card access etc.) depending on the installation requirements and

characteristics. For the various control systems, see the relevant instructions.

The installer undertakes to instruct the user about correct automa-

tion operation, also pointing out the actions to be taken in case of

emergency.

18) MAINTENANCE

WARNING! Before proceeding to any maintenance, disconnect the

mains power supply and, if the battery is fitted, one of its poles.

These are the check and maintenance operations to be carried out:

•

Check the condition of lubrication of the metal racks once a year.

•

Keep the sliding track always clean and free from debris.

•

Occasionally clean the photocell optical elements.

•

Have a qualified technician (installer) check the correct torque limit

setting.When any operational malfunction if found, and not resolved,

disconnect the mains power supply and request the assistance of a qualified

technician (installer). When the automation controller is out of service, you

can activate the manual release device (see paragraph on “

Emergency

manoeuvre

”) in order to set the pinion idling and therefore allow the gate

to be opened and closed by hand.

19) NOISE

The environmental noise produced by the gear-motor in normal operation

conditions is constant and does not exceed 70 dB (A).

21) SCRAPPING

Materials must be disposed of in conformity with the current regula-

tions.

In case of scrapping, the automation devices do not entail any particu-

lar risks or danger. In case of materials to be recycled, these should be

sorted out by type (electrical components, batteries, copper, aluminium, plastic

etc.).

20) DISMANTLING

When the automation system is disassembled to be reassembled on

another site, proceed as follows:

• Disconnect the power supply and the entire external electrical installation.

• In the case where some of the components cannot be removed or are

damaged, they must be replaced.

21) MALFUNCTION: CAUSES and REMEDIES

21.1) The gate does not open. The motor does not turn.

1) Check that the photocells or the sensitive edges are not dirty, engaged,

or not aligned. Proceed accordingly.

2) Check that the electronic appliance is correctly supplied. Check the

integrity of the fuses.

3) Check that the functions are correct by means of the control unit diagnosing

LEDs (see relevant instructions).

Identify causes for faults, if any. If the LEDs show persisting start control,

check that no radio controls, start buttons or other control devices keep the

start contact activated (closed).

4) If the control unit does not work, it must be replaced.

If after having carried out the checks listed above the problem persists,

replace the actuator.

21.2) The gate does not open. The motor turns but the movement does

not take place.

1) The manual release is activated. Reset the power-driven operation.

2) Check that the gate had reached the mechanical end-of-stroke stops.

Release and move the gate manually, and reset the power-driven control.

Check and correct the end-of-stroke bracket position.

3) Check that the mechanical setting of the gate is not defective, for example

if the wheels are blocked or the rack is not aligned with the pinion, etc.

4) Check that the clutch does not slip. If it does, load it as described in the

relevant paragraph.

If after having carried out the checks listed above the problem persists,

replace the actuator.

WARNING! Correct controller operation is only ensured when the data

contained in the present manual are observed. The company is not to

be held responsible for any damage resulting from failure to observe

the standards relating to safety, installation and good technical

practice, as well as the instructions contained in the present manual.

The descriptions and illustrations contained in the present manual

are not binding. The Company reserves the right to make any altera-

tions deemed appropriate for the technical, manufacturing and com-

mercial improvement of the product, while leaving the essential

product features unchanged, at any time and without undertaking to

update the present publication.

Summary of Contents for LEM7

Page 2: ...2 LEM7 LEM8F Ver 01 D811025A_01 ...

Page 31: ...LEM7 LEM8F Ver 01 31 D811025A_01 ...

Page 32: ......