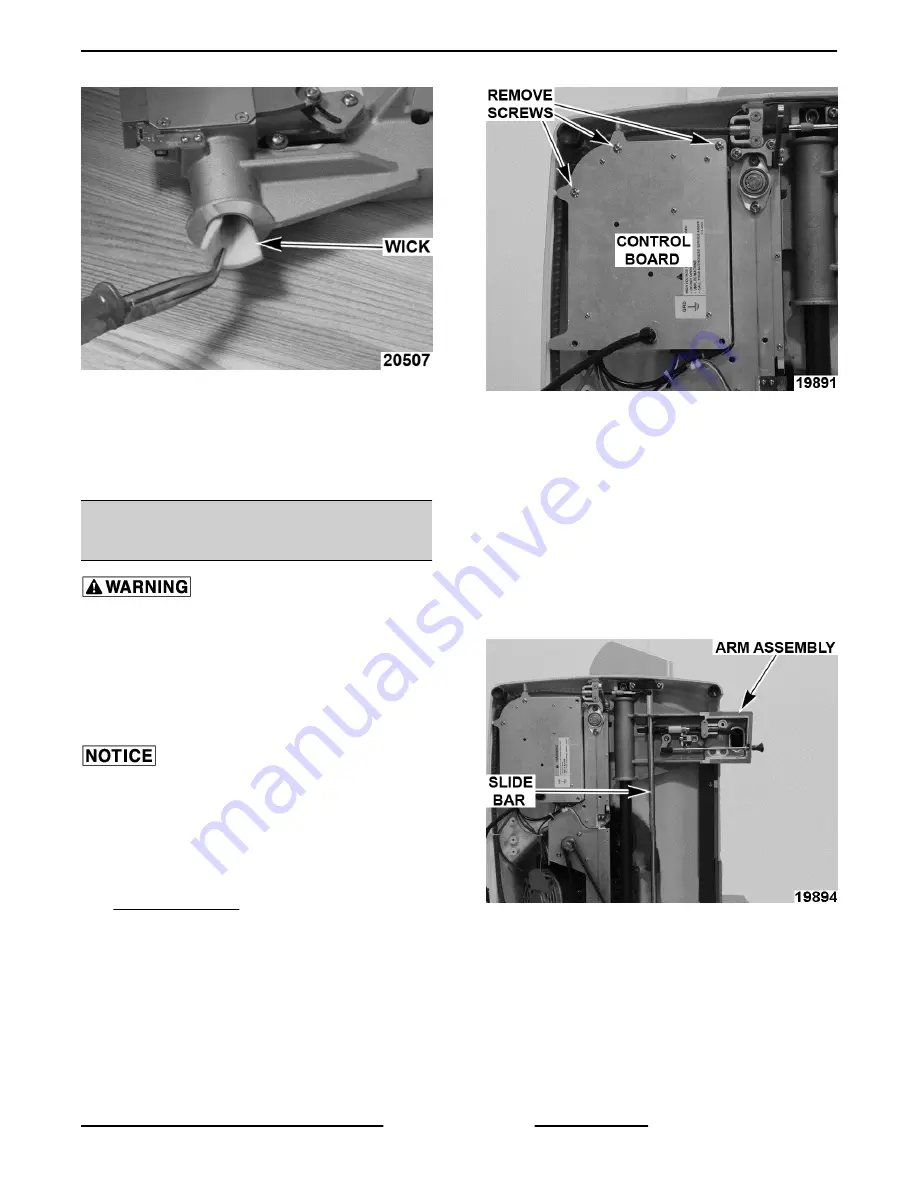

Fig. 79

4.

Coat new wick with Berkel oil and install in

transport arm.

5.

Reverse procedure to install.

6.

Check slicer for proper operation.

SLIDE BAR SWITCH TEST (X13,

X13A)

Certain procedures in this section require

electrical test or measurements while power is

applied to the machine. Exercise extreme caution

at all times. If test points are not easily accessible,

disconnect power and follow lockout / tagout

procedures, attach test equipment and reapply

power to the test.

Certain components in this system are subject to

damage by electrostatic discharge (ESD) during field

repairs. An ESD kit is required to prevent damage. The

ESD kit must be used anytime the circuit board is

handled.

1.

Remove product table as outlined under

PRODUCT TABLE.

2.

Place slicer on its side, so it is resting on motor

housing.

3.

Remove screws to access control board.

Fig. 80

4.

Plug slicer in.

5.

Verify 5VDC between J4-1 and J4-5.

A.

If voltage is not present, check all

connections.

B.

If connections are good, replace control

board.

6.

Verify 5VDC between J4-4 and J4-5.

7.

Supporting the arm assembly, squeeze the slide

bar to the unlocked position and lower assembly.

Fig. 81

A.

Verify 0VDC between J4-4 and J4-5

anytime slide bar is squeezed into the

unlocked position.

B.

Verify 5VDC when slide bar is released

again.

8.

If voltage is not present, replace slide bar switch.

X13 SLICER - SERVICE PROCEDURES AND ADJUSTMENTS

Page 29 of 36

F25332 Rev. A (0718)