NOTE:

Loose hoses and Hydraulic Components will not always

show a visual sign of leakage, however even small leaks

can allow air into the system. It is very important to

tighten all hoses and mounting bolts on Hydraulic

Components monthly.

PRESSURE SETTINGS

There are three critical pressure settings on your Bender

that affect its performance These pressures should be

checked weekly. The following is a brief description of

the pressures and the roles they play.

BACK PRESSURE

Back pressure is actually resistance pressure applied to

the Back Gates during the bending process. The

pressure is transferred to the Back Gates via the Bottom

Cylinder and Chain Assembly. The setting itself is

controlled by the Sequence Valve. This “resistance”

pressure is required in order to form the shape of the

Tubing as the Radius Die advances. This pressure is

read on the Gauge attached to the Sequence Valve

located near the front left side of the machine. The

pressure reading is taken as the Dies advance through

the Gates during a bend.

The normal operating back

pressure should be set at 1600 P.S.l.

In some cases it

may be necessary to adjust this

pressure. (See Three Inch and Stainless Bending

Procedures found on pages 21 & 22.)

If the back pressure needs adjusting, proceed as follows:

1. Turn the machine on.

2. Place a Radius Die and set of Back Shoes in position.

Tubing will not be required for this operation.

3. Advance the Radius Die until it begins to pass through

the Gates.

4. At this time read the pressure shown on the Gauge

attached to the Sequence Valve. (See figure 3-B)

5. If an adjustment is required, loosen the locking nut

that secures the adjusting screw.

6. To increase the pressure, turn the adjusting screw

clockwise; to decrease, counterclockwise. Never

exceed 2000 P.S.I.

RETURN PRESSURE

This pressure reading is also taken on the gauge located

near the front left side of the machine. The purpose of this

pressure is to maintain adequate tension on the chain

assemblies during the retract sequence. This is important

so that the Gates close in unison with the Radius Die.

Upon initiating the return sequence, Hydraulic Oil is “split”

and redirected, so that an equal portion is transferred to

the Top Cylinder and Bottom Cylinder simultaneously. If

the pressure is set too high, the machine will groan and

strain when reversing as the Top Cylinder tries to overcome

the Bottom Cylinder. If the pressure is too low, the Gates

may hesitate or remain open when the Radius Die retracts

as the Top Cylinder receives more Oil than the Bottom

Cylinder. It is seldom necessary to readjust this pressure

setting.

The normal operating return pressure should

be set at 350 P.S.l.

This pressure reading is taken as the

Radius Die retracts

just after it releases from the Back

Shoes.

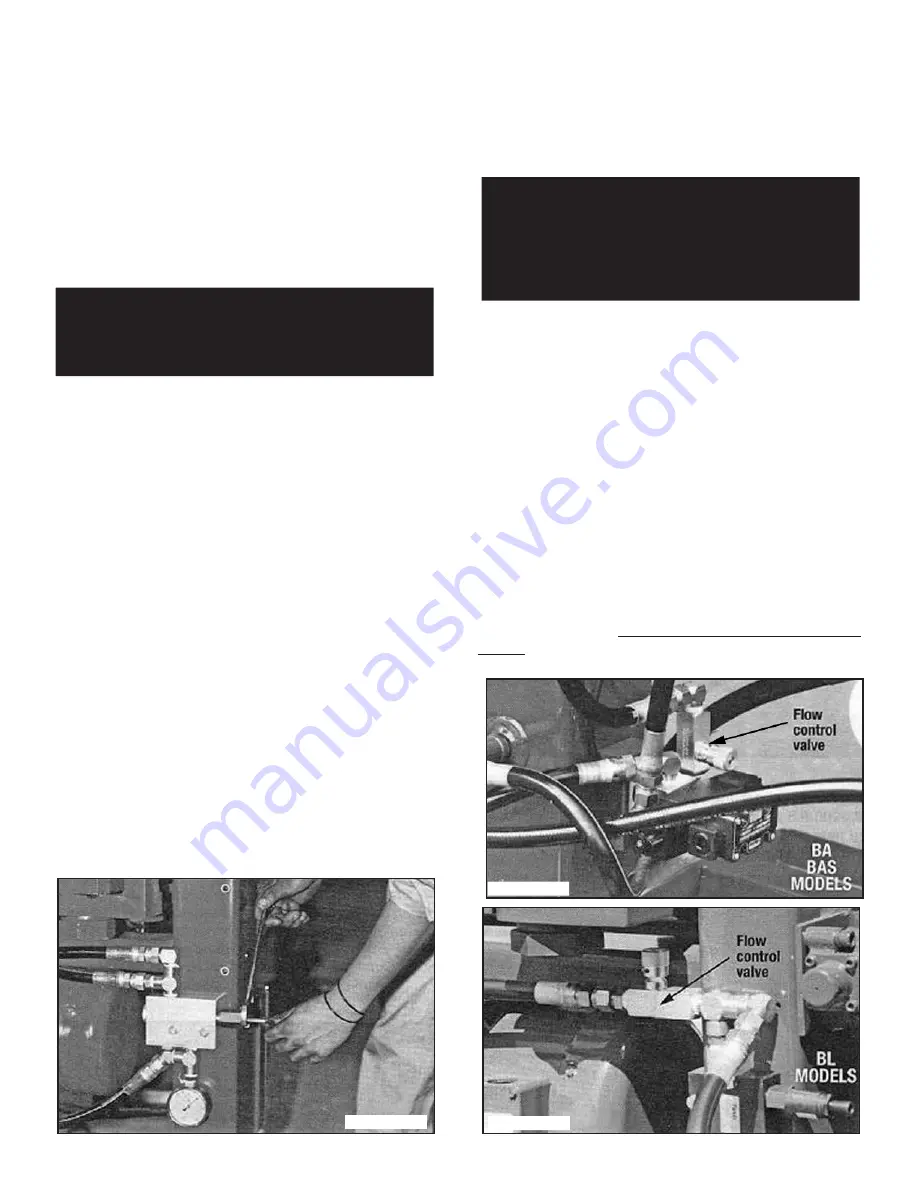

This pressure setting is controlled by the flow

Control Valve. (See figure 1-A and 2-A)

CAUTION!

Never exceed 2000 P.S.I. for the back pressure

unless specifically instructed to do so by the

factory for special circumstances. If it is necessary

to increase the back pressure, always remember to

return the pressure back to 1600 P.S.I. before

proceeding with the next bend.

CAUTION!

Improper back pressure settings will cause Tubing

to wrinkle and/or collapse and may also damage

machine and/or Dies.

Figure 1-A

Figure 2-A

Figure 3-B

34 Bender Operation Manual

Summary of Contents for BB 1302-BA

Page 50: ...50 Bender Operation Manual...

Page 51: ...Bender Operation Manual 51...

Page 56: ...56 Bender Operation Manual...

Page 57: ...Bender Operation Manual 57...

Page 58: ...58 Bender Operation Manual...

Page 59: ...Bender Operation Manual 59...

Page 60: ...60 Bender Operation Manual...

Page 61: ...Bender Operation Manual 61...

Page 62: ...62 Bender Operation Manual...

Page 63: ...Bender Operation Manual 63...

Page 64: ...64 Bender Operation Manual...

Page 65: ...Bender Operation Manual 65...