7. Visually check bronze bushings for excessive wear.

Replace bushings if inside diameter is greater than

2.005” or more.

(See figure 3-A)

8. After check is completed, reverse steps and adjust

chain assembly as described on page 34.

IMPORTANT NOTE:

Be sure to Grease the Zirk Fittings on each side of the

barrel after re-installation of Gate Assemblies.

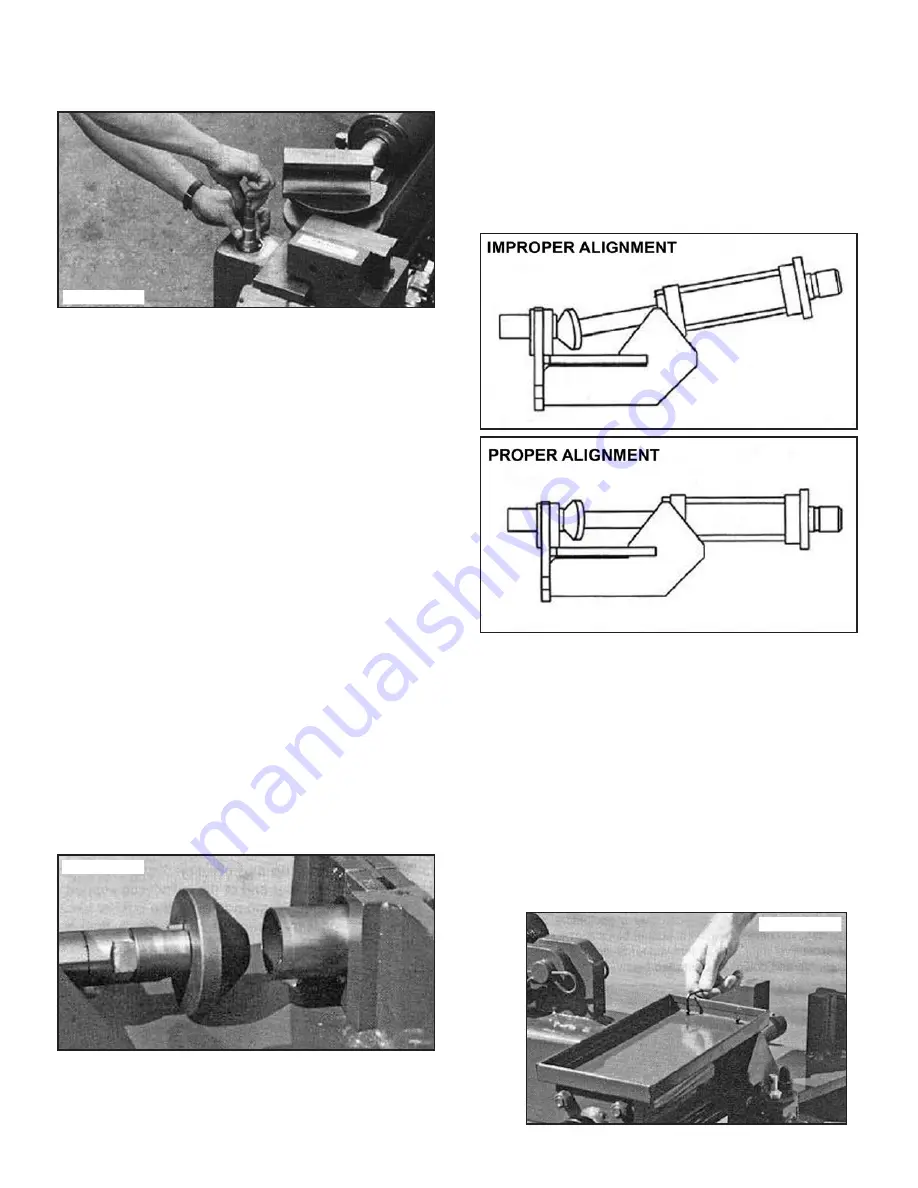

ALIGNING THE SWAGING

BOX CYLINDER

The Swaging Cylinder should be checked periodically for

proper alignment. If the Swaging Cylinder is not square

or centered with the swaging Clamp Blocks, the Tubing

will not expand correctly.

NOTE:

If the Swaging Cylinder is damaged or bent due to

improper use, there is no way to correct this, other than

total replacement of the cylinder.

To properly check the Swaging Cylinder for proper

alignment, follow the steps outlined below:

1. Turn the machine on.

2. Install a HPF-300 or similar Tool on the ST-1 Adapter.

(See figure 3-B)

3. Position a section of squarely cut 2” Tubing

approximately 12” long into the clamp block area

using the necessary HAC Adapter Collar.

4. Gently snug the Collar back into the Clamp Blocks by

gently pushing back on the Collar Assembly.

5. Hold the Tubing securely making sure that the

HAC-300 is square within the Clamp Blocks.

6. Advance the Tool forward until it just makes contact

with the Tubing.

7. At this time, the Tool should contact the complete

circumference of the Tubing end simultaneously. If

the Swaging Cylinder is out of alignment or the Cylinder

shaft is bent, then the Tool will only partially contact

the Tubing circumference. (See illustrations)

8. If the Swaging Cylinder is out of alignment, proceed

as follows to make proper adjustments:

9. Turn the machine off until all necessary adjustments

are made.

10. Remove the two allen bolts securing the Swaging

Tool tray using a 1/8” Hex Wrench. (See figure 3-C)

11. Loosen the four (4) 1/2” nuts (or bolts) attaching the

cylinder to the Swaging box using a 3/4” socket or

Open-End Wrench. It is not necessary to completely

remove the Nuts or Bolts. (See figure 1-A)

Figure 3-A

Figure 3-B

Figure 3-C

38 Bender Operation Manual

Summary of Contents for BB 1302-BA

Page 50: ...50 Bender Operation Manual...

Page 51: ...Bender Operation Manual 51...

Page 56: ...56 Bender Operation Manual...

Page 57: ...Bender Operation Manual 57...

Page 58: ...58 Bender Operation Manual...

Page 59: ...Bender Operation Manual 59...

Page 60: ...60 Bender Operation Manual...

Page 61: ...Bender Operation Manual 61...

Page 62: ...62 Bender Operation Manual...

Page 63: ...Bender Operation Manual 63...

Page 64: ...64 Bender Operation Manual...

Page 65: ...Bender Operation Manual 65...