Insta

ll

at

i

on

2 1 1

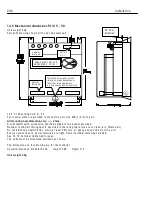

1 4.7.1. 2 V ent

i

ng mode

l

s PL/X 1 8 5 - 2 6 5 us

i

ng back pane

l

aperture

Use the temp

l

ate prov

i

ded to ass

i

st

i

n cutt

i

ng the aperture

i

n the

back pane

l

Th

i

s

i

s the preferred method of mount

i

ng because

i

t a

ll

o w s the

max

i

mum amount of coo

l

a

i

r to f

l

o w over the heats

i

nk of the

dr

i

ve.

For

i

nsta

ll

at

i

ons requ

i

r

i

ng a 5 0 C

i

nterna

l

enc

l

osure amb

i

ent th

i

s

method

i

s necessary.

The source of c

l

ean, f

il

tered, coo

l

, dry a

i

r for vent

i

ng the un

i

t must

arr

i

ve at the bottom of the enc

l

osure. It must then be ab

l

e to f

l

o w

free

l

y to the rear of the backp

l

ate as sho w n. There must be no

obstruct

i

ons to the f

l

o w of a

i

r on

i

ts

j

ourney to the back aperture.

There

i

s a very po w erfu

l

fan

i

ntegra

l

to the PL/X w h

i

ch w

ill

suck

th

i

s a

i

r

i

nto the rear of the un

i

t. A fter pass

i

ng over the heats

i

nk

i

t

i

s exhausted at the top and bottom of the un

i

t. The exhaust a

i

r

must then be extracted from the enc

l

osure v

i

a roof mounted fans

capab

l

e of a throughput rate spec

i

f

i

ed

i

n the rat

i

ng tab

l

e. Note,

w hen ca

l

cu

l

at

i

ng the requ

i

red a

i

r throughput,

i

t

i

s necessary to

cons

i

der the d

i

ss

i

pat

i

on of a

ll

heat generat

i

ng components. The

d

i

ss

i

pat

i

on

i

n w atts for the PL/X , ma

i

n fuses and

li

ne reactors,

i

s

prov

i

ded

i

n the re

l

evant sect

i

ons.

1 4.7.1. 3 V ent

i

ng mode

l

s PL/X 1 8 5 - 2 6 5 us

i

ng standoff p

ill

ars

Th

i

s method of mount

i

ng may be the on

l

y pract

i

ca

l

techn

i

que

i

n

retrof

i

t

i

nsta

ll

at

i

ons w here cutt

i

ng an aperture

i

n the back pane

l

i

s

not poss

i

b

l

e.

The un

i

t

i

s prov

i

ded w

i

th a mount

i

ng k

i

t cons

i

st

i

ng of four 5 0mm

p

ill

ars. The max

i

mum enc

l

osure amb

i

ent temperature us

i

ng th

i

s

method

i

s 3 5 C. There must be no obstruct

i

ons to the f

l

o w of a

i

r

on

i

ts

j

ourney to the rear of the PL/X .

The reason for the reduced amb

i

ent rat

i

ng

i

s that some of the

exhaust a

i

r may be rec

i

rcu

l

ated over the heats

i

nk,

l

ead

i

ng to a

l

oss

of eff

i

c

i

ency. A ny steps that can be taken to m

i

n

i

m

i

se th

i

s are

advantageous. (The 3 5 C rat

i

ng app

li

es to

i

nsta

ll

at

i

ons w here there

i

s not comp

l

ete separat

i

on of the

i

ncom

i

ng a

i

r from the coo

li

ng

a

i

r).

If

i

t

i

s poss

i

b

l

e to prov

i

de an a

i

r duct w

i

th an aperture area of

greater than 1 8 0 sq. cm. that can transport a

i

r un

i

mpeded to the

rear of the PL/X , then th

i

s so

l

ut

i

on

i

s as effect

i

ve as the back

pane

l

aperture method descr

i

bed above.

A

i

rf

l

o w

Roof fans

Door mounted

a

i

r f

il

ter

i

ntake

A

i

rf

l

o w

A

i

rf

l

o w

B ack p

l

ate

1 0 0 mm m

i

n

ex tens

i

on

B ack p

l

ate

1 0 0 mm m

i

n

ex tens

i

on

m

i

n

i

mum gap 5 0 mm

A

i

rf

l

o w

Roof fans

Door mounted

a

i

r f

il

ter

i

ntake

A

i

rf

l

o w

A

i

rf

l

o w

Back p

l

ate

Dr

i

v e on 5 0 m m

standoff p

ill

ars

Summary of Contents for PLX

Page 2: ...2 Contents ...

Page 202: ......