3 6

Bas

i

c app

li

cat

i

on

Answ

e

r

.

2) Mak

i

ng current. If the PL/X has been

i

nstructed to start mak

i

ng current, but the ma

i

n contactor

has not yet c

l

osed, then the motor w

ill

not be ab

l

e to rotate. Th

i

s w

ill

cause the PL/X to phase further

forw ard

i

n an attempt to produced the des

i

red speed. If the contactor then c

l

oses

i

t w

ill

present a stat

i

onary

motor armature on a fu

ll

y phased forw ard stack, stra

i

ght on to the supp

l

y, produc

i

ng destruct

i

ve current. A

ll

th

i

s w

ill

occur

i

n a fe w cyc

l

es of current w h

i

ch

i

s far too fast for the speed

l

oss a

l

arms to operate.

So

l

ut

i

on.

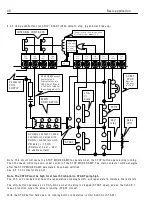

1) Insert an aux

ili

ary norma

ll

y open contact on the ma

i

n contactor

i

n ser

i

es w

i

th the RUN

i

nput on T 3 1.

2) A

l

ternat

i

ve

l

y use contactor w

i

r

i

ng method sho w n

i

n 4.3.2.

Qu

e

st

i

on

. P

l

enty of systems do not appear to suffer from fa

il

ures due to open

i

ng the contactor

i

ncorrect

l

y so

w hy

i

s

i

t so

i

mportant?

Answ

e

r

. If the armature current

i

s d

i

scont

i

nuous, w h

i

ch

i

s very common, then there

i

s much

l

ess stored

i

nduct

i

ve energy and the current a

l

so goes to zero every current cyc

l

e. Th

i

s makes

i

t h

i

gh

l

y un

li

ke

l

y that a

destruct

i

ve s

i

tuat

i

on occurs. The h

i

gh r

i

sk s

i

tuat

i

ons are regenerat

i

ve app

li

cat

i

ons and cont

i

nuous current

modes. Even

i

n these cases

i

t does not a

l

w ays resu

l

t

i

n a destruct

i

ve sequence.

Qu

e

st

i

on

. Even

i

f the contactor operates accord

i

ng to the recommendat

i

ons ho w

i

s protect

i

on afforded

i

f the

contactor co

il

supp

l

y

i

s

l

ost.

Answ

e

r

. Th

i

s

i

s a d

i

ff

i

cu

l

t prob

l

em to so

l

ve us

i

ng e

l

ectron

i

cs. The on

l

y re

li

ab

l

e

i

nsurance

i

s to

i

nsert a D C

sem

i

conductur fuse

i

n the armature c

i

rcu

i

t. Th

i

s fuse shou

l

d open before the thyr

i

stor

j

unct

i

on fa

il

s.

Qu

e

st

i

on

. W hat

i

f the gr

i

d system fa

il

s tota

ll

y?

Answ

e

r

.

Th

i

s

i

s not as bad as

l

os

i

ng the contactor co

il

supp

l

y. Most

i

nsta

ll

at

i

ons natura

ll

y have other

l

oads

that prov

i

de a safe d

i

scharge path before the contactor opens.

Qu

e

st

i

on

. W hat

i

f the gr

i

d system fa

il

s for a fe w cyc

l

es? (Bro w n outs)

Answ

e

r

. The PL/X

i

s des

i

gned to r

i

de through these k

i

nds of supp

l

y d

i

ps. A s soon as

i

t

l

oses synchron

i

sat

i

on

the armature current

i

s quenched. The armature vo

l

tage

i

s then mon

i

tored so that w hen the supp

l

y returns

the PL/X p

i

cks up

i

nto the rotat

i

ng

l

oad at the correct speed.

Qu

e

st

i

on

. W hat other sorts of prob

l

ems occur?

Answ

e

r

. Most prob

l

ems occur w hen users are retro-f

i

tt

i

ng the PL/X

i

nto an ex

i

st

i

ng system. Somet

i

mes these

systems have prev

i

ous

l

y contro

ll

ed the contactor v

i

a a PLC or Dr

i

ve hea

l

thy re

l

ay. These contro

l

systems

may not be

i

nterfaced correct

l

y w

i

th PL/X and s

i

tuat

i

ons occur that drop out the contactor too qu

i

ck

l

y, or

br

i

ng

i

t

i

n too

l

ate.

A nother common prob

l

em

i

s that the contactor

i

s contro

ll

ed correct

l

y for norma

l

runn

i

ng but

i

ncorrect

l

y

dur

i

ng

j

ogg

i

ng or emergency stopp

i

ng.

A nother

i

nstance

i

s the

i

nsta

ll

at

i

on

i

s des

i

gned correct

l

y but the comm

i

ss

i

on

i

ng eng

i

neer uses a

l

oca

l

op

stat

i

on to get each PL/X go

i

ng, that has an

i

n bu

il

t contro

l

prob

l

em.

Summ

a

r

y

.

Us

e

th

e

PL

/X to

c

ont

r

o

l

th

e

m

a

i

n

c

ont

ac

to

r

fo

r

STO

P

, STA

R

T,

j

ogg

i

ng

a

nd

e

m

e

r

g

e

n

c

y stop. A

ll

s

e

qu

e

n

c

i

ng o

cc

u

r

s

a

utom

a

t

i

ca

ll

y. F

i

t s

e

m

i

c

ondu

c

to

r

fus

e

s

i

n th

e

AC supp

l

y

a

nd

a

r

m

a

tu

r

e

c

ir

c

u

i

ts.

Th

e

c

ost of

a

fus

e

i

s m

a

r

g

i

n

a

l

c

omp

a

r

e

d to th

e

c

ost of

r

e

p

a

iri

ng

a

d

a

m

a

g

e

d d

ri

v

e

a

nd suff

e

ri

ng m

ac

h

i

n

e

downt

i

m

e

a

nd

e

ng

i

n

ee

r

ca

ll

out

c

osts.

Summary of Contents for PLX

Page 2: ...2 Contents ...

Page 202: ......