Technical staff manual

3.

USER’S MANUAL

3.1.

Control Panel

The main control element of the boiler is the electronic board which controls all boiler’s operation. The

electronic board’s microprocessor collects and processes signals from the control and safety sensors. All

information about the boiler’s condition is displayed on the LCD display in real-time operation mode.

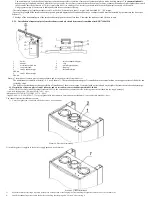

All control over the boiler is effectuated from the control panel, the appearance of which is shown on

Scheme 3.

If a remote control is connected to the boiler, then control is effectuated from it, the buttons of the control panel

are inactive.

In the left part of the control panel there is a pressure gauge, indicating the pressure inside the heating circuit.

Heat carrier pressure in the CHmust be not lower than 1 bar (with pressure lower than 0,5 bar the safety system

will be switched on and it would be impossible to put the boiler into operation).

In the center of the control panel there is an LCD display, showing the temperature in currently active mode at

normal operation of the boiler (at operation in the heating mode it shows the heat carrier temperature in the

heating system by the outlet from the boiler, at operation in the DHW mode –the DHW temperature by the

outlet from the boiler). In case of failure the error code appears on the display instead of temperature. The

boiler’s error codes are represented in the p.14.1 (page 34).

The symbols on display show the boiler’s operation mode. Around the display there are 6 boiler control

buttons. The designation of the control buttons and of the symbols shown on display are represented in the

tables 2 and 3 respectively.

3.2.

Boiler operation modes

The boiler can operate in the following modes:

-

Standby mode (see p. 3.2.1);

-

DHW mode (see p. 3.2.2);

-

combined mode

(see p. 3.2.3, page 10);

-

heating mode (see p. 3.2.4, page 10);

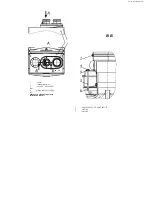

When the boiler is connected to the power line, it automatically sets up to the mode in which it was before

being switched off from the power line. Change of boiler’s operating modes is effectuated by pressing the K5

button on the boiler’s control panel (see p. 3.1, page 8). The sequence of the boiler’s operating modes change is

represented on Scheme 4.

Scheme 3. Boiler’s control panel

Control buttons purpose ________________________________________________________________ Table 2

Designation

Function

K1

DHW temperature increase

K2

DHW temperature reduction

K3

Heating temperature increase

K4

Heating temperature reduction

K5

Choosing the boiler’s operation mode, switching the boiler on/off (see p. 3.2)

K6

Reset of the boiler’s electronic board blocks (RESET)

Purpose of symbols shown on display ______________________________________________________ Table 3

Symbol

Is always glowing

Flickering

Antifreeze function operating symbol (see p. 3.3.1,

page 10)

Presence of flame on the burner

Standby mode

Boiler in the DHW standby mode

Boiler operating in the DHW mode

Boiler in the heating standby mode

Boiler operating in the heating mode

RESET

Error code, reset request

Error code, maintenance service required

Parameters programming (see p. 13.3.1, page 30)

Parameter number displayed

Parameter value displayed

Remote control connected

Remote control connection error

Summary of Contents for NEVALUX-8230

Page 35: ...Assembly is performed in reverse order Scheme 23 Heat exchanger dismantling...

Page 41: ...48...

Page 47: ...Ignition and ionization plugs in the assembly pos 67...

Page 54: ......

Page 55: ......