User and technical staff manual

32

14.

SEARCH FOR FAILURES AND THEIR ELIMINATION

14.1

Error codes

Contamination of the boiler’s operation, caused by the refuse or faulty operation of any of its systems, is accompanied

by an appropriate error code displayed on the boiler’s control panel (see p. 3.1 , page. 8) which facilitates failure

detection.

Error codes, possible reasons and methods of troubleshooting are represented in the table 4.

Table 4

Cod

e

Failure

Reason of failure

Troubleshooting

01

Defects related to the faulty

ignition

Boiler doesn’t operate *

Gas supply disturbance

Open the stop valve on the gas pipeline

Check pressure in the gas cylinder

(liquefied gas)

Address to gas service

Failure of ignition plug

Replace the ignition plug

Electric circuit of ignition plug is damaged

Check electric circuit and contacts

Wrong gap between ignition plug and burner

blade

Install a gap (5

+0,5

mm).

Spark of electrode of ignition plug slips on the

shell of combustion chamber

Bend a shell of combustion chamber in the

place of ignition plug installation

Ignition plug is contaminated

Wipe the plug from dust and degrease

Failure of ionization plug

Replace the plug

Electric circuit of ionization plug is damaged

Check the electric circuit and contacts

Wrong gap between ionization plug and

burner blade

Install a gap (3+

0,5

mm).

The ignition transformer is out of order

Replace the ignition transformer

Electric circuit of the ignition transformer is

damaged

Check the electric circuit and contacts

The burner block is contaminated

Clean the burner block (see p. 16.1.1, page

37)

Electric circuits of gas supply regulator are

damaged

Check the electric circuit and contacts

Gas supply regulator doesn’t work

Replace the gas supply regulator

The thermo relay is out of order (normally

closed at temperature up to 90 °С)

Replace thermo relay

Electric circuit of thermo relay (overheating

sensor)is damaged

Check the electric circuit and contacts

02

Heat carrier overheating

The boiler doesn’t work *

The heating system is contaminated

Clean the heating system

The thermo relay is out of order (normally

closed at temperature up to 90 °С)

Replace thermo relay

Air lock in the heating system

Open air outlet valve

(see p. 16.2.2.5 , page 39)

Filter is the heating system is contaminated

Clean the filter

Bypass valve is out of order or wrong installed

Check proper installation of the details of

bypass valve and replace it if necessary

Pump or air outlet valve is out of order

Replace the pump or air outlet valve

The pump relay on the electronic board is out

of order

Replace the electronic board

Gas supply regulator doesn’t work

Replace the gas supply regulator

Gas supply regulator is not adjusted

Adjust the gas supply regulator (see

section 11, page 25)

Electric circuit of thermo relay(overheating

sensor) is damaged

Check electric circuit and contacts

Summary of Contents for NEVALUX-8230

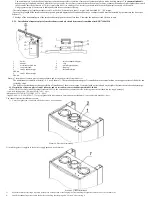

Page 35: ...Assembly is performed in reverse order Scheme 23 Heat exchanger dismantling...

Page 41: ...48...

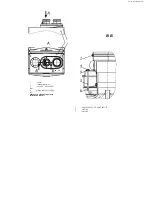

Page 47: ...Ignition and ionization plugs in the assembly pos 67...

Page 54: ......

Page 55: ......