Technical staff manual

3.3.3.

Boiler’s operation in heating mode with an external (outdoor) temperature

sensor

For an optimal heat carrier temperature regulation in the CHdepending on external

temperature it is recommended to use an external (outdoor) temperature sensor. The

correction of heat carrier temperature in the CHis effectuated in accordance with the

external temperature and regulation coefficient Kd (see Scheme 5). The electronic

board automatically discerns the presence of an external sensor and effectuates the

temperature regulating function. At heat carrier temperature setting in the CHthe

value of the Kd coefficient is shown on the boiler’s control panel’s display instead of

the temperature value. The regulation coefficient may be set in a range between 0 and

9,9.

Please see the recommendations on connection of the external sensor in p. 10.3.3 (page

24).

3.3.4.

Boiler’s operation at low /high source voltage

When the source voltage comes outside the range 190 ÷ 250 V the electronic board renders the boiler into the

standby mode. At this moment the symbol – - is shown on the boiler’s display and the boiler does not react on

pushing the control buttons.

In 30 seconds after voltage recovery in the range of 190 ÷ 250 V the boiler’s operation is automatically restored

in the mode in which the boiler was before, before voltage comes outside the range 190 ÷ 250 V.

4.

BOILER SERVICE

In order to provide long-term and failure-free boiler operation and to keep its operational characteristics it

is necessary to regularly effect the examination, treatment and technical service of the boiler.

Examination and treatment must be effected by the boiler’s owner.

Boiler technical service can be effectuated only by a specialized service organization not less than

once a year. The recommended time for technical service if before the heating season start.

Boiler technical service might be required more often than once a year, in case of intensive work of the

boiler in a premise where there is much dust in the air or in case of higher water hardness. The

unscheduled boiler cleaning must also be effectuated also in case if in the premise where the boiler is

installed there were construction or reparation works and much construction dust and waste got into the

boiler.

ATTENTION! Works connected with technical service are not warranty liabilities of the

manufacturer company and are effectuated by the customer’s cost.

4.1.

Examination

Every time before putting the boiler into operation, and in case of the boiler’s operation during the

heating season once a day, it is necessary to:

-

Make sure that there are no highly flammable objects next to the boiler or next to the smoke exhausters;

-

Make sure that there is no smell of gas inside the premise, if the smell of gas in the premise was detected

you must address to the gas facilities service;

-

Make sure that there are no heat carrier leakages in the heating and hot water supply systems, in case if

leakages are detected you must address to a special service organization;

-Make an external examination of the smoke exhausters in order to detect damages. If smoke exhauster damages are

detected, you must address to a special service organization

4.2.

Boiler treatment

-The heat carrier filters of the heating and DHW supply systems must be cleaned regularly, especially

before the beginning of the heating season. The DHW filter must also be cleaned at water flow

reduction in the DHW supply line;

- The air from the heating system must be removed from time to time (see section 10, page 22);

-The heating system must be filled with the heat carrier until the needed pressure is reached (see section 10, page 22);

-The boiler must be kept clean, for this it is necessary to remove dust from the boiler’s upper surface regularly, and

also to clean the boiler’s casing first with a wet rag and then with a dry rag. In case of bigger dirtying you should first

wipe the boiler’s casing with a wet rag, moistened in a neutral detergent, and then with a dry rag. It is prohibited to use

detergents of heightened effect and containing abrasive particles, gasoline and other organic solvents for cleaning the

casing’s surface and plastic details.

ATTENTION! In case of using water as a heat harrier, do not change the water in the heating system unless

necessary, it will permit to reduce scale deposit in the heat exchanger. Before coming long-term idleness of the

boiler in winter time it is necessary to drain the water from the heating system in order to avoid damaging the

pipelines when it freezes.

ATTENTION! All boiler treatment operations must be effectuated only after it is disconnected from the

network and has cooled down.

4.3

Operations effectuated at technical service

At technical service the following operations are effectuated:

1)

Cleaning of the burner block (burner);

2)

Cleaning the heat exchanger from soot and cleaning (washing) the heat exchanger’s pipes from scale deposit (if

necessary);

3)

Cleaning (washing) the secondary heat exchanger from scale deposit (if necessary);

4)

Replacement of the seals in the gas system, the heating and hot water supply systems;

5)

Checking the boiler’s gas, heating and hot water supply systems’ air-tightness;

6)

Lubrication of moving connections (if necessary), it is recommended to use thick lubricant greases on silicone base;

7)

Checking of safety devices, they must work without failures;

8)

Checking of air pressure in the expansion tank (once in 3 years), the pressure must be 1,0 bar;

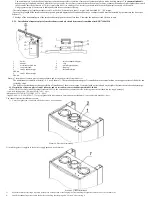

T external

CHT

Scheme 5. Schedule of dependency of the temperature in the CHfrom the external temperature

Summary of Contents for NEVALUX-8230

Page 35: ...Assembly is performed in reverse order Scheme 23 Heat exchanger dismantling...

Page 41: ...48...

Page 47: ...Ignition and ionization plugs in the assembly pos 67...

Page 54: ......

Page 55: ......