Consolidated 2900-40 Series POSRV Instruction Manual

| 59

© 2020 Baker Hughes Company. All rights reserved.

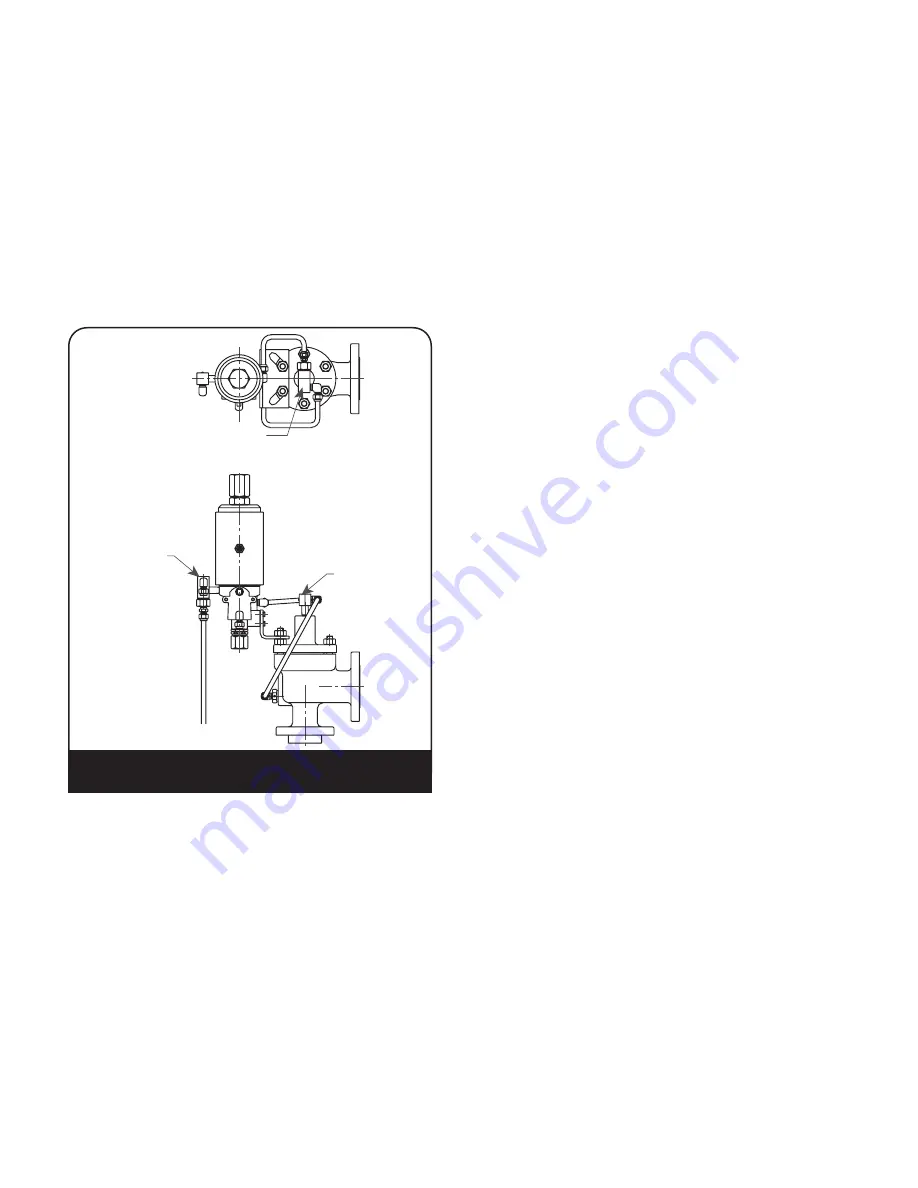

XXII. 2900-40 Series POSRV Options

When the pilot operated safety relief valve is not vented

directly to atmosphere, it is possible to build up

backpressure in the discharge line. This is typical in

situations where several valves manifold into a common

discharge header. Should the discharge line pressure

exceed the valve inlet pressure, it could cause the disc to

lift and allow reverse flow through the main valve. This

situation can be eliminated through the use of the Backflow

Preventer.

A.1 Disassembly Instructions

1. Remove Shuttle Plug from Shuttle Base by unscrewing

counterclockwise.

2. Remove Shuttle Ball, Tube Filter, and O-Rings and

discard.

A.2 Cleaning

1. If required, clean parts to remove all rust, burrs, scale,

organic matter, and loose particles. Parts are to be free

of any oil or grease except for lubrication as specified in

this instruction.

2. Cleaning agents used shall be such that effective

cleaning is assured without injuring the surface finishes

or material properties of the part.

3. Acceptable cleaning agents include demineralized

water, nonphosphate detergent, acetone, and isopropyl

alcohol. Parts must be blown dry or wiped dry after

cleaning.

4. If you are using cleaning solvents, take precautions to

protect yourself from potential danger from breathing

fumes, chemical burns, or explosion. See the

solvent’s Material Safety Data Sheet for safe handling

recommendations and equipment.

5. It is not recommended to “sand blast” internal parts as it

can reduce the dimensions of the parts.

A.3 Parts Inspection

1. Shuttle Base: Galling or excessive wear on the threads.

Check for any corrosion or pitting.

2. Shuttle Plug: Galling or excessive wear on the threads.

Check for any corrosion or pitting.

A.4 Reassembly Instructions

Lubricate O-Rings with silicone grease Baker Hughes P/N

SP505.

1. Assembly of Field Test Connection / Backflow

Preventer Assembly.

a. Insert one of the Small O-Rings into the Shuttle

Base counter bore.

b. Insert the Tube Filter into the Shuttle Base.

c. Insert Shuttle Ball inside of Tube Filter.

d. Insert the other Small O-Ring into the Shuttle Plug

counter bore. Install Larger O-Ring into groove

located on OD of Shuttle Plug.

e. Thread Shuttle Plug into Shuttle Base, wrench

tighten.

Backflow

Preventer

Backflow

Preventer

Field Test

Connection

Figure 45: Field Test Connection /

Backflow Preventer Option

A. Backflow Preventer