40 |

Baker Hughes

© 2020 Baker Hughes Company. All rights reserved.

b. For disc sizes “K” through “T”, reassemble the

Disc using a new O-Ring, O-Ring Retainer, and

new Lock Screws. Refer to Table 10 for the proper

torque.

(i) Prior to assembly of the Disc into the Disc

Holder, remove the Disc Retainer from the back

of the Disc. Use 1000 grit grinding compound

on the bearing surface to grind the Disc into the

Disc Holder to properly establish the bearing

surface.

(ii) Place the Disc Retainer into the groove in

the disc. The Disc with the Disc Retainer

should “snap” into the Disc Holder pocket with

moderate finger or hand force. Do not use

excessive force to assemble these parts. Be

sure that the Disc is free to “wobble” after it is in

place.

3. Set the Disc Holder (disc side down), on the work

surface. Place a small amount of 1000 grit grinding

compound onto the ball end of the Main Valve Piston

and place it in the disc holder pocket. Turn the Main

Valve Piston clockwise, and then counter clockwise,

to seat the Main Valve Piston. Clean all grinding

compound from parts.

4. Place the Spring down onto the Disc Holder.

5. Place the Guide over the Disc Holder. (DO NOT

DROP.) If Bellows is present, the weight of the Guide

will slightly compress the Bellows.

6. Place the Guide Gasket in the Base.

7. Install disc guide assembly. Use the same lifting tool

(see Figure 14) as was used during disassembly, then

carefully lower it into the Base.

8. Using a small amount of Silicone Grease supplied with

soft goods replacement kit, rub a small amount on the

seals and O-Rings prior to assembly.

9. Take the Main Valve Piston and measure and cut

diagonally the proper length of Guide Ring material to

fit in the groove of the Main Valve Piston. Allow 1/16 of

an inch (1.59 mm) gap between the ends for proper fit.

10. For Teflon seals make sure of the integrity of the

Teflon seal and seal spring. Install Disc Seal on Disc

outside diameter on the opposite end of the disc seat

as shown in Figure 28.

If an O-Ring seal is used, it is installed in the groove

between where the Guide Ring is installed and where

a Spring Energized Seal would be installed (Figure

28).

11. Install the Guide Ring(s) onto the Main Valve Piston.

If there is more than one Guide Ring, stagger the cut

locations 180° apart.

12. To prevent seal damage during assembly, check the

chamfer on the bottom of the Cover Plate for burrs. If

any sharp edges exist, polish the chamfer.

13. Insert Main Valve Piston (energize seal/O-Ring side

first) into bottom of Cover Plate. Continue pushing

Main Valve Piston into Cover Plate, being careful

not to pinch the guide rings. Push Main Valve Piston

in until bottom of Main Valve Piston is even with the

bottom of the Cover Plate.

14. Install 1/4” MNPT pipe plug into Cover Plate where

dome line connects.

Table 12: Torque Required for Each Round of

Pattern

Round

Percentage of Required Torque

1

Wrench Tight

2

25

3

60

4

100

5

100

XVI. Reassembly of the 2900-40 Main Valve (Cont.)

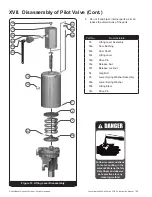

Main Valve Piston

Main Valve

Piston O-Ring

Guide Ring

Figure 28: Main Valve Piston