www.atmos.cz

26-GB

Instruction manual - GB

GB

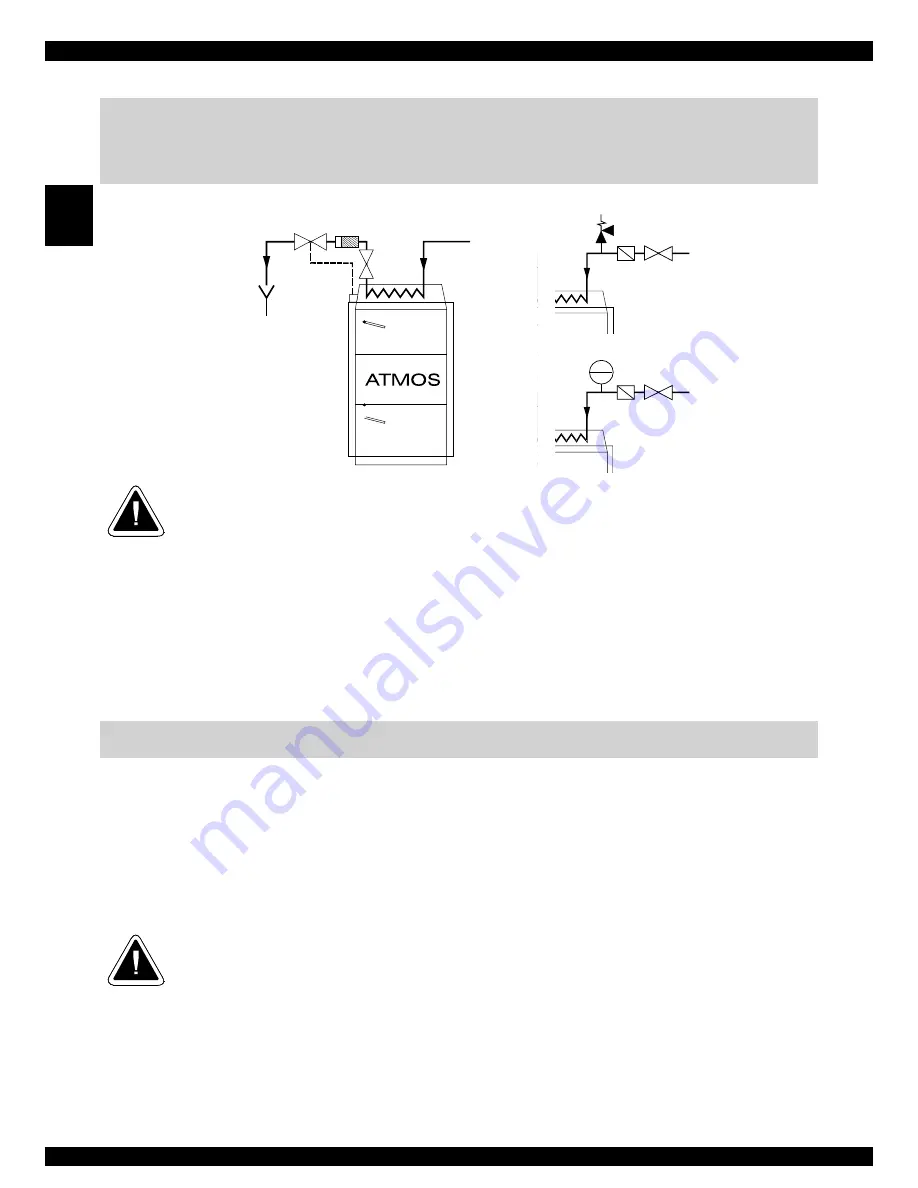

27. Connection of overheat protecting cooling loop with a safe-

ty valve Honeywell TS 131 - 3/4 ZA or WATTS STS20

(valve opening temperature 95 - 97 °C)

CAUTION

– in compliance with the EN ČSN 303-5, the cooling loop must not be used for

any other purpose than overheat protection (never for heating hot potable water).

The TS 131 - 3/4 ZA valve or WATTS STS 20 valve, the sensor of which is placed in the rear

of the boiler, prevents overheating in the following way: if the boiler water temperature rises above

95 °C, the valve opens and allows water from public water supply system to enter the cooling loop.

This water then absorbs the excessive energy and exits to the sewer. In case that a non-return flap

valve has been installed to the cooling loop water inlet for the purpose of preventing reversed water

flow (which might be caused by pressure drop in the public water supply system), the cooling loop

must be fitted with a 6 - 10 bar safety valve or with an expansion vessel of minimum 4 l volume. The

boiler must be protected against overheating at all times. If not, its damage or burst may occur.

28. Operating instructions

Preparing boilers for operation when burning pellets

Before putting the boiler in operation you must make sure that the system is filled with water

and bled. Boiler must always operate in accordance with the instructions contained in this manual to

achieve high quality and safety of the functionality of the system.

The system may only be operated

by adult persons.

The commissioning of the boiler must be done in accordance with this manual and

the operation manual attached to the pellet burner by a qualifiedperson.

CAUTION - The boiler may only be put in operation by a qualifiedpersoninaccord

-

ancewith valid regulations and standards, trained by the manufacturer.

Before we proceed heating-up with the pellets do some operations.

Ensure that all lids and doors are fully closed. Check that the burner is well drawn towards the

boiler through its gasket and the limit switch position-stop is in its place. Also check the tube between

the burner and conveyor so that it is stretched and at a sufficient angle to ensure that the pellets can

drop without difficulty into the burner.

They must not cumulate inside the tube!

The screw convey-

or should be at a maximum of 45° angle otherwise the boilers might not reach their nominal output.

Honeywell TS 130– 3/4 A (95°C) valve

WATTS STS 20 (97°C)

sewer

filter

valve

water supply from

public water system

pressure: 2 - 6 bar

temperature: 10 – 15°C

safety valve 6 – 10 bar

non-return

flap valve

non-return

flap valve

expansion tank of min. 4 l volume