34

of

54

TECHNICIANS' manual

Core200

8.3.3 Maintenance after a short period of machine

inactivity

“Short machine downtime” refers to a period of time

exceeding one working week.

If the machine is switched back on after this period, all

of the water inside the hydraulic circuits must be replaced

as indicated in par. 6.10 .

All the scheduled maintenance operations must also

be performed - see the previous par. 8.3.1 .

8.3.4 Dispensing group maintenance

Replace the dispensing group's shower screen

(B)

and

group gasket

(D)

on a quarterly basis (it is recommended

to use original spare parts only), by proceeding as follows:

•

Unscrew the screw

(A)

;

•

Remove the shower screen containment ring

(C)

;

•

Replace the group shower screen

(B)

and the rubber

group gasket

(D)

;

•

Reassemble the components.

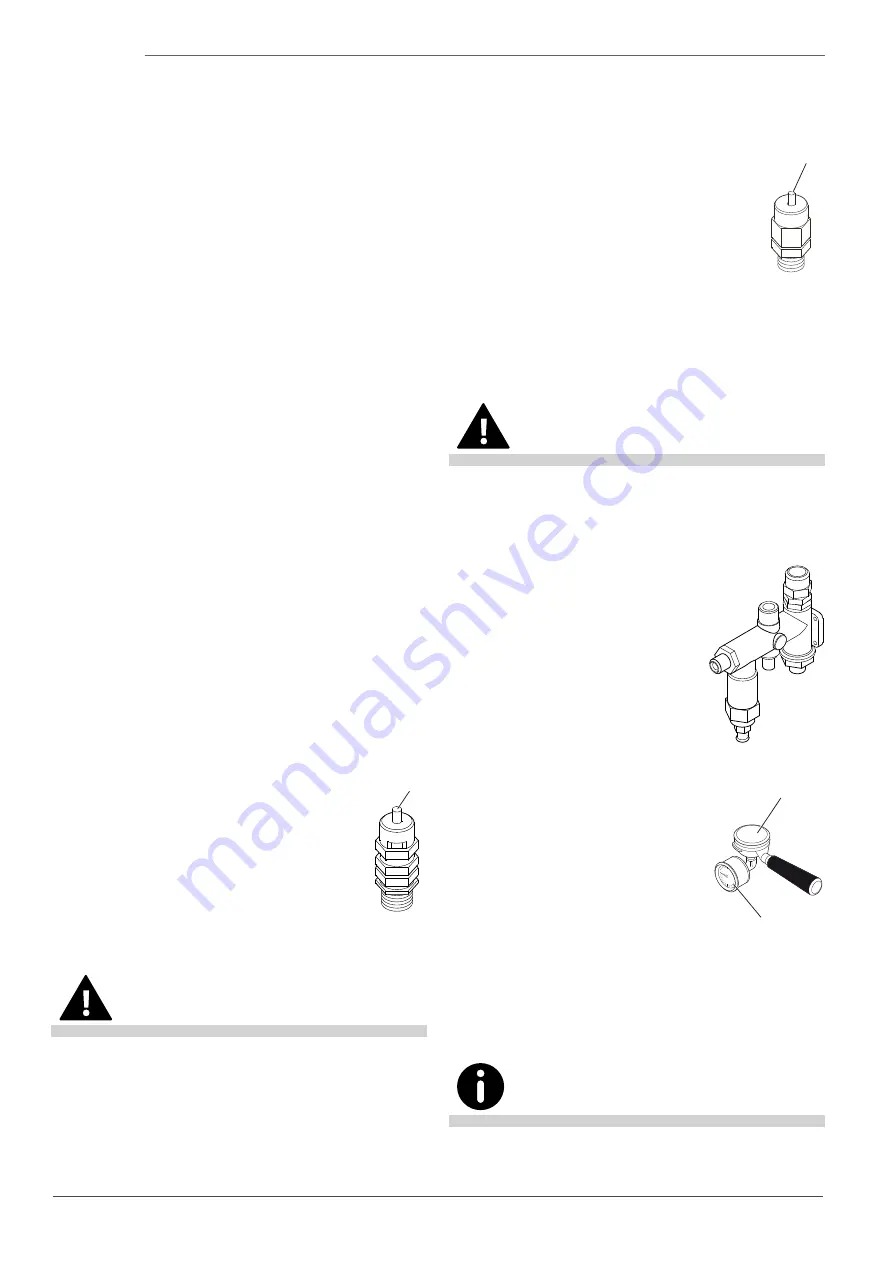

8.3.5 SAFETY VALVE check

The pressure relief valve is one of the main compo-

nents for machine safety. Therefore, it is important to

carry out the following checks:

First check :

•

Eemove the machine's upper grille;

•

Use pliers to pull the valve pin

(E)

upwards;

•

If the pin will not budge, it probably means that the

valve is encrusted with limestone and must

be replaced.

Second check :

•

Turn the machine off;

•

Close off the pressure switch contacts;

•

Turn the machine back on and wait for the

pressure in the heating unit to rise;

•

Check that the valve is working correctly at the ma-

ximum pressure of 0,19 MPa (1,9 bar).

If any malfunctions are detected, the valve must be replaced. Only

use the Manufacturer's original Safety Valves.

8.3.6 NEGATIVE PRESSURE VALVE check

First check:

•

Remove the machine's upper grille;

•

Use pliers to push the valve pin

(

F

)

downwards;

•

If the pin will not budge, it probably

means that the valve is encrusted with

limestone and must be replaced.

Second check:

•

Turn the machine off;

•

Open the steam valves and release all the pres-

sure from inside the heating unit;

•

Turn the machine back on and check that the valve

is closing normally.

If any malfunctions are detected, the valve must be replaced.

8.3.7 NON-RETURN DRAIN VALVE check

The non-return drain valve is an

important component for the correct

operation of the machine. Perform the

check as follows:

•

Activate the dispensing

groups for about 30 seconds;

•

Attach a filter holder

(

G

)

with

a pressure gauge (available

on request) to the dispensing

group;

•

Activate the dispensing group,

and use the pressure gauge

(

H

)

to monitor the pressure as

it increases up to 0,8-0,9 MPa

(8-9 bar);

•

Check that the pressure is

increasing due to the heated

water expanding until it

reaches approximately 1,2 MPa

(12 bar): when this value is reached, it confirms

that the valve is working correctly and the seals

and solenoid valves are tight;

•

Stop dispensing;

•

Repeat the check on the other dispensing groups.

If any malfunctions are detected, the valve must be replaced.

E

F

G

H

Summary of Contents for 10003318

Page 53: ......