16

of

54

TECHNICIANS' manual

Core200

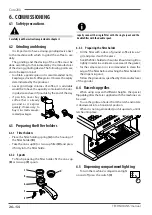

2.8.1 Group

In this system, the dispensing group

(1)

is heated

by a thermosiphonic circuit

(2)

connected to the heat

exchanger

(3)

. The same water is used when dispens-

ing coffee which ensures that all coffees are the same

temperature:

•

The activation of the solenoid valve and the pump

allows cold water to enter the exchanger

(3)

through

the injector

(4)

;

•

the heating unit water is carried from the exchanger

(3)

to the group

(4)

for dispensing;

•

the pump allows the water flow pressure to increase

to 8-9 bar for dispensing.

The injector

(4)

and the flow reducer

(5)

are important

components for the operation of the dispensing group. To

increase the coffee extraction temperature, remove the

flow reducer

(5)

or replace it with one that has a bigger

diameter. To decrease the temperature, replace it with one

that has a smaller diameter. If necessary, the exchangers

can be replaced by removing the flange and disconnecting

the relative hydraulic circuit pipes. These operations should

be carried out when the machine has been switched off

and has cooled down: always replace the seals..

2.8.2 Boiler

The heating unit is made of copper sheet metal

(1)

.

The heat exchangers are assembled onto this unit and

are in turn connected to the dispensing group. The

water used for dispensing coffee is taken directly from

the heat exchanger. During the dispensing process, cold

water is sent inside the exchanger by means of the mo-

tor pump. Inside the heat exchanger, cold water and the

pre-existing hot water are mixed together in order to

obtain the optimal water temperature for coffee infusion.

The heating unit is electrically heated by an electric

heating element immersed in the water

(2)

.

2.8.3 Pressure relief safety valve

The pressure relief safety valve has a calibra-

tion of 1.9 bar in order to ensure that the pres-

sure in the steam heating unit does not exceed

2.1 bar. Should a fault occur, the capacity of the

valve is such as to be able to eliminate all the

excess pressure in the heating unit..

2.8.4 Negative pressure valve

The purpose of the negative pressure valve

is to prevent liquids from back-flowing through

the steam nozzle when they are being heated.

Furthermore, the excess air inside the heating

unit is removed during the machine's heating

phase.

3

Water inlet

Coffee

dispensing

5

3

4

DISPENSING IN PROGRESS

2

3

1

IDLE

2

1

Summary of Contents for 10003318

Page 53: ......