32

of

54

TECHNICIANS' manual

Core200

Component

Type of operation

Quarterly

Yearly

HEATING UNIT

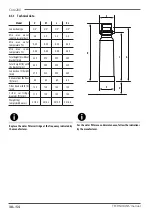

Replace the electric heating element if it becomes faulty or malfunctions.

•

Do not replace the heating element with a more powerful one. Before making any changes,

please contact the Manufacturer.

•

If the thermostat of the heating element is triggered, reset it by pressing the central button

of the thermostat. However, before starting the machine up again, check what caused the

problem.

•

If the heating unit insulation needs to be removed, restore the insulation after the mainte-

nance work has been completed.

•

Remove and clean the heating unit level probes.

•

Check whether there is any limescale build-up on the heating element.

•

If there is a lot of limestone build-up, this indicates that the water filter has not been replaced,

or that the softener has not been regenerated.

•

When replacing any components, always replace the relative gasket as well.

X

SAFETY VALVE

SCNR VALVE

Check that the safety valves and non-return drain valves are operating properly, as indicated

in par. 8.3.5 - 8.3.7.

If these need to be replaced due to malfunction, repeat the check with the newly-installed valve.

X

HYDRAULIC CIRCUIT

•

Check whether there is any limescale build-up in the hydraulic circuit.

•

When replacing any components, always replace the relative gasket as well.

•

If there is a lot of limestone build-up in the machine's hydraulic circuit, this indicates that

the water filter has not been replaced, or that the softener has not been regenerated.

•

Take care in areas where the water is very hard. The water filter will need to be replaced

more frequently and the water softener will need to be regenerated more often, especially

if the machine is used intensively

X

DRAIN

•

Check for any leaks on the water mains and sewer connections.

•

Check the state of the drain tray and the drain connection tube.

X

DISPENSING GROUP

Check the efficiency of the dispensing group's solenoid valve.

X

WATER and STEAM NOZZLES Check the condition of the nozzles and clean the sprayer.

X

DOSING DEVICE

Check and clean the volumetric dosing device by removing any oxidation from the tips.

X

ELECTRIC SYSTEM

Check and clean the volumetric dosing device by removing any oxidation from the tips.

X

MOTOR PUMP

Check that the motor pump is working correctly and adjust if necessary.

X

If any work is carried out on the machine electronics when the machine is still live, any guarantee will automatically be invalidated.

All original spares are available on the Manufacturer’s website. The Manufacturer may provide the list of spare parts recommended for

the maintaining the various versions of the machine.

Summary of Contents for 10003318

Page 53: ......