page 4

ABOUT THE RC10T2

Congratulations on your new RC10T2 model truck

kit purchase. We would like to tell you a little bit about your

new truck and its history. Team Associated developed the

first version of the RC10T in 1990. This was the first

production truck to be designed from the ground up to be a

truck. Before the RC10T, trucks were merely modified

buggies with truck parts added. Since the original version,

there were two additional models of the RC10T, the #7011

Sport Truck kit and the #7035 Team Truck kit, our race truck

version.

With the RC10T2 we have moved trucks to the next

level of performance. Associated has known for years about

the advantages of an aluminum chassis. Starting from the

ground up we developed a completely new one. This new

computer-designed aircraft aluminum alloy hard anodized

chassis provided us with improved front-to-rear rigidity, chas-

sis side clearance, and reduced weight, but still providing you

with a low center of gravity. The hard anodized finish im-

proves its durability. We designed along with it our new

integral rear end assembly. This consists of the rear bulk-

head, shock strut, transmission case, motor plate and guard.

When all of this is assembled you have one of the most rigid

production main chassis structures available on any R/C

truck today. This overall improved stiffness is one of the more

obvious refinements.

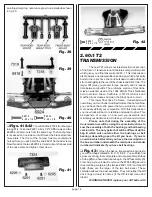

Part of the improved rear structure includes the new

2.60:1 low profile Assoc. transmission. It features a larger

diff for increased torque capacity and reduced maintenance.

It will also allow you to run even higher rpm modified motors

without the normal gearing problems. This will give you the

improved quickness and top speed you need to dominate

your competition. But the design changes do not end here.

The new transmission also has a new two piece motor plate

and motor guard assembly. At the same time you will find a

new lighter rear bulkhead and rear shock strut which inter-

lock with the transmission case.

You will find our latest suspension and steering

geometry changes give you a more aggressive yet easier

handling truck with improved traction and rough track perfor-

mance. The ease with which your new truck handles benefits

both the new and experienced driver. You will find an

improved battery mounting system designed for both six or

seven cell battery packs. It can handle matched packs or

stick packs and is designed to let you use either plugs or hard

wire solder connections.

In the #7012 sport version you will find bronze

bushings throughout, gold anodized shocks, three piece

wheels with multi surface tires, dog bones and stub axles,

mechanical speed control (with forward and brakes only) and

a kit DS Spec motor. In the original #7036 ball bearing version

you will find a new, Associated-designed, universal dogbone

axle which is stronger and lighter and made to closer toler-

ances. To put the power to the ground this version also

includes some of the same tires we race with. The Proline

XTR compound “Edge” front tires and "Mini Pin" rear tires

(with front and rear foam inserts) for improved steering and

traction. You still get our race proven hard anodized PTFE

coated shocks and PTFE shock pistons, Associated Torque

Control transmission clutch, and one piece racing wheels.

To cover all of these new race enhancements both kits have

a new racing truck body with a low center of gravity design.

How does this truck perform? The pre-production

prototype TQ’ed both stock and modified classes and won

the Stock National title at the 1994 ROAR Truck Nationals in

Garden Grove, Calif. It then TQ'd and won the first NORRCA

Electric Truck World Cup. It also TQ'd at the 1995 Winter

Championships in Tampa, Florida.

All of the above changes mean your new RC10T2

truck kit is the finest race truck available. After you have

driven your truck you will find out why Associated has won

more World Championship and National titles than any other

manufacturer. If you refer back to pages two and three of this

manual you will see pictured the major features of the ball

bearing truck kit. The back cover shows the bushing kit

features.

BEFORE YOU BEGIN

Many people will feel the photos are detailed enough

to think they will not need to read the instructions. This is not

true. In addition to all of the photos there is important

information to assemble your truck found only in the text.

Even though you have the best truck kit available, if you want

the best COMPLETED TRUCK then you will want to put it

together correctly by following both text and photos.

This manual also covers two versions of the truck so

you will also find sections that are specific to one version

only. When possible we have combined the same steps for

both versions. This was done to eliminate confusion and to

show you how to correctly assemble the parts if you ever

decide to upgrade your sport version.

❑

Step 1

OPEN THE PARTS BAGS WHEN THE STEP

SPECIFIES, NOT BEFORE, otherwise you’ll get the parts

mixed up and then you will have trouble assembling your

truck. When you open each main bag for the first time, check

the contents against the separate parts list sheet (accompa-

nying the manual) for that bag. This sheet shows the

contents of each bag by part number and quantity. All parts

bags are referred to by number or name in the instructions.

The unlabeled bags inside the main parts bags share the

same bag number as the bag they came out of.

❑

Step 2

KEEP THE PARTS SEPARATE. While

building the truck you will sometimes be working with several

bags at the same time. Try not to confuse the parts from one

bag with the parts from another. Large paper plates (espe-

cially picnic plates with partitions) are ideal for both keeping

parts separate and spreading them out where you can find

them easier. Mark the plates with bag numbers and dump the

parts into them. When the parts are used up, relabel the plate

for the next bag.

❑

Step 3

CHECK FOR SUPPLEMENTARY SHEETS