Page 57 of 60

25.

Handling of Iron Tip

Introduction

Soldering is a technique which connects a metal to another metal by alloy reaction.

Solder material melts, but mother material (metal pieces on the work-piece) never melt by soldering.

There are three important factors (Three great factors of soldering) for the alloy reaction as follows:

Cleaning the metal surface

Formation of alloy layer which by melting solder and connecting to metal surface

Heat source which should be maintained in suitable temperature in order to form alloy layer by

soldering.

Solder iron tip is related to the formation of alloy layer and the heat source.

So, It is very important for a good care of solder tip to make a stable soldering.

<Handling of iron unit>

Apollo soldering tip, HI-TIP (AS, HQ, TM and DC model) realized the high performance and long

life by using oxygen-free copper as a mother material with special iron plating and careful after

treatment.

Usually, the life of the tip is about 50,000 points. However, if it is used at more than 400

o

C or if

solder with a bad solder feeding position, the life is shorten extremely to approximately 5,000 points

caused by "Iron plate Corrosion". Therefore, please use it with suitable condition. If the condition

is proper, the life exceeds 100,000 points.

1) Attach an iron tip, then the vinyl resin coating on the iron tip is cracked and peel off during the

temperature rising. Please use it after making pre-soldering by the solder including flux.

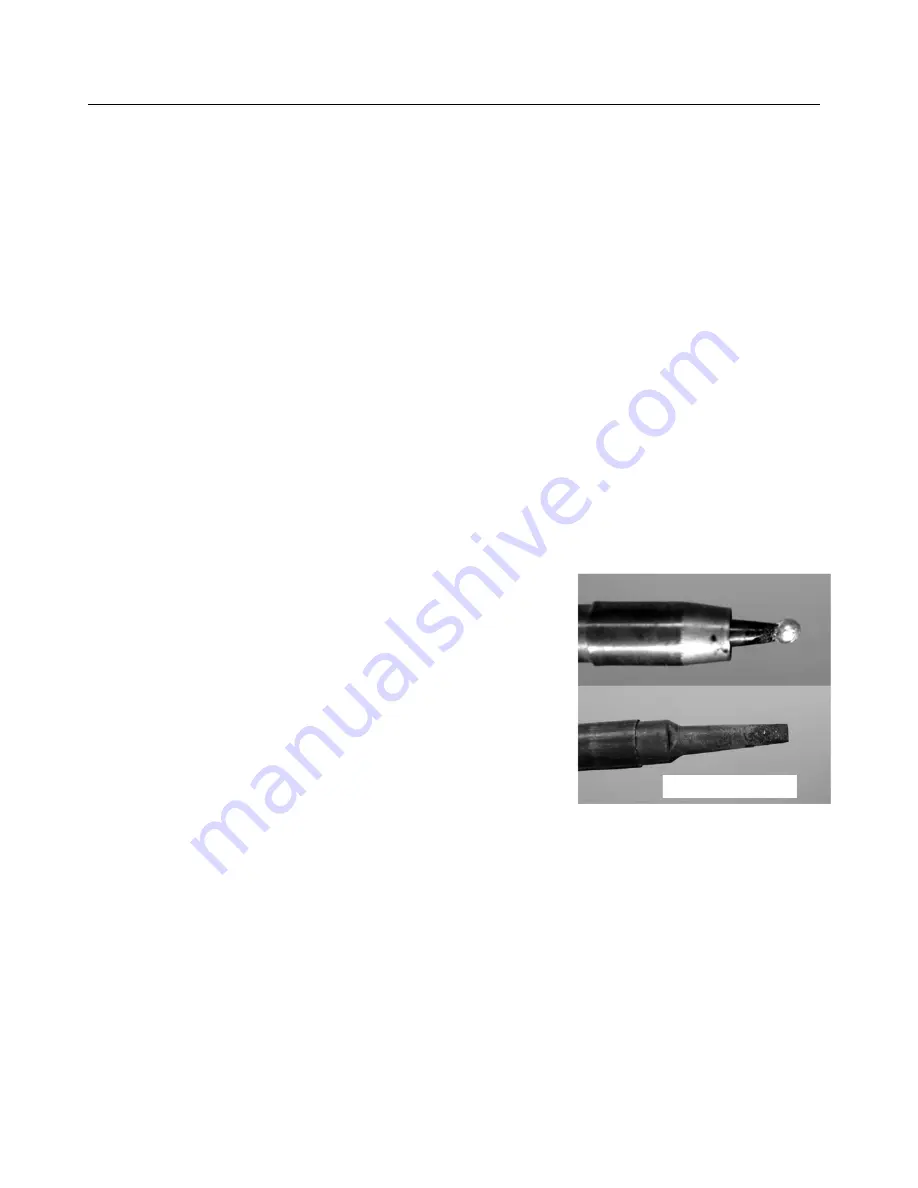

2) Iron tip should be placed at iron stand after pre-solder on

iron tip. If tip is left at the stand without solder after cleaning,

the tip oxidizes and cannot be getting wet with solder.

3) If flux or some oxide residues were left over the iron tip,

please remove them with back of a cutting edge like a

cutter lightly.

Do NOT file the iron tip because iron plating may be peeled

off, then the iron tip cannot be getting wet with solder.

If a tip is not getting wet with solder…..

Remove pre-solder on tip completely.

Brush the iron tip lightly with a brass wire brush.

Melt a new solder including flux on the tip or dip the iron tip into a soldering pot.

Remove the needless solder with a wet sponge.

Make pre-solder soon

The tip will wet with solder by the above process.

Oxidize iron tip