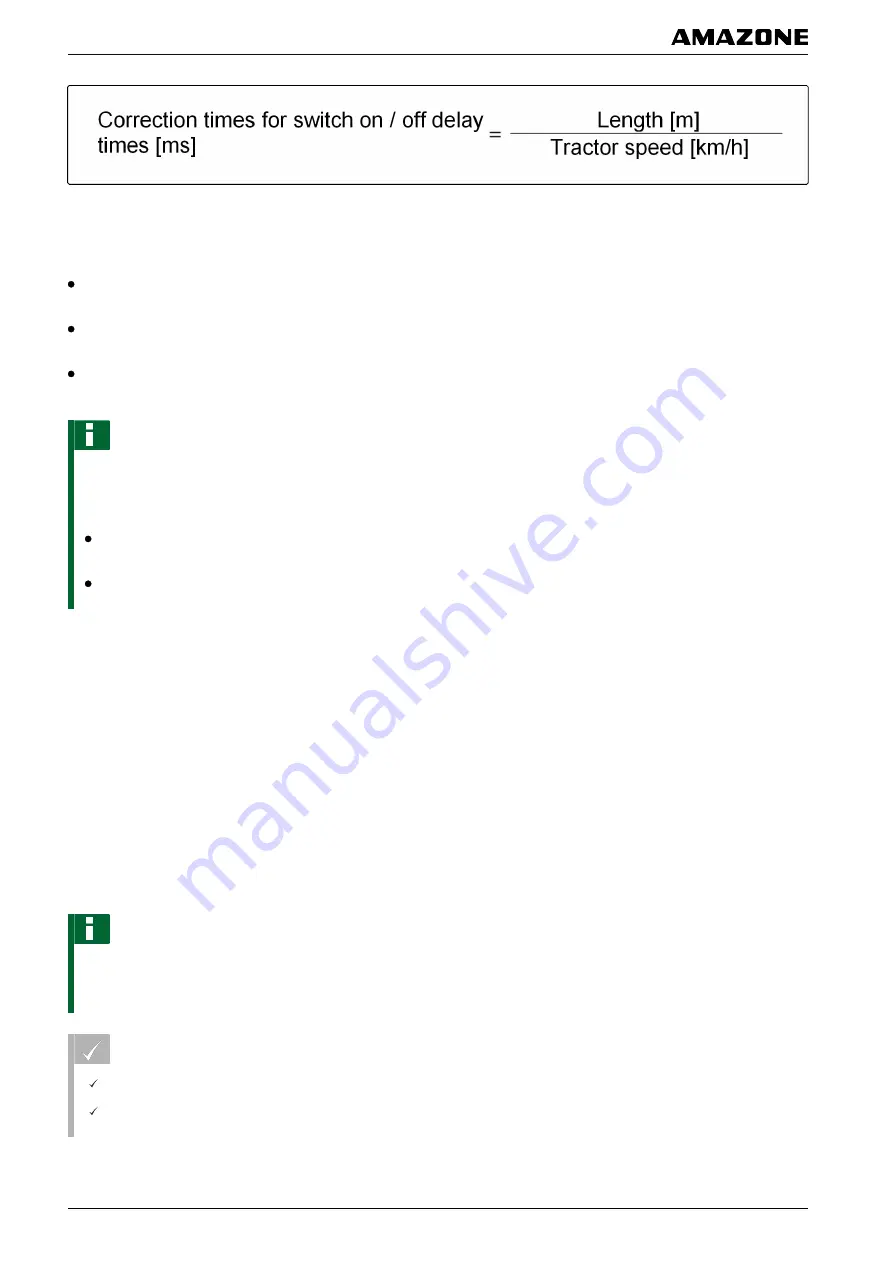

The on/off point delay for seeding technology for

switching on and off is influenced by the following

factors:

Delivery times depending on the seed type, conveyor

section and the blower fan speed

Driving behaviour depending on the forward speed,

acceleration and braking

GPS accuracy depending on the correction signal

and update rate of the GPS receiver

NOTE

For precise switching at the headlands – especial-

ly for seed drills – the following points are abso-

lutely necessary:

RTK accuracy of the GPS receiver (update rate

min. 5 Hz)

Constant speed when driving in or out of the head-

lands

3.11 Checking the switch-on and -off times

When the part-width sections are switched on , it takes a

few hundred milliseconds until the application/spreading

actually starts. The switch-on delay can cause underlaps

in working the field. When the part-width sections are

switched off, it also takes several hundred milliseconds

until the application/spreading actually stops. This

switch-off delay can cause overlaps in working the field.

The switching times compensate for these delays with

switching the part-width sections on and off.

NOTE

The switching times are only shown for ISOBUS seed

drills and ISOBUS sprayers. The switching times can

only be changed through the implement controls.

REQUIREMENTS

ISOBUS implement is connected

The AMATRON 3 is started in ISOBUS mode, see

page 18

013796

K | Using the GPS switch| Entering the basic settings for GPS switch

MG5560-EN-II

| B.1 | 2016.07

90