1. Select

"Setup"

>

"Settings"

>

"Basic settings"

>

"Vol-

ume"

.

2. Enter a value between 1 and 20.

3. Confirm the entry.

NOTE

The AMATRON 3 cannot be muted.

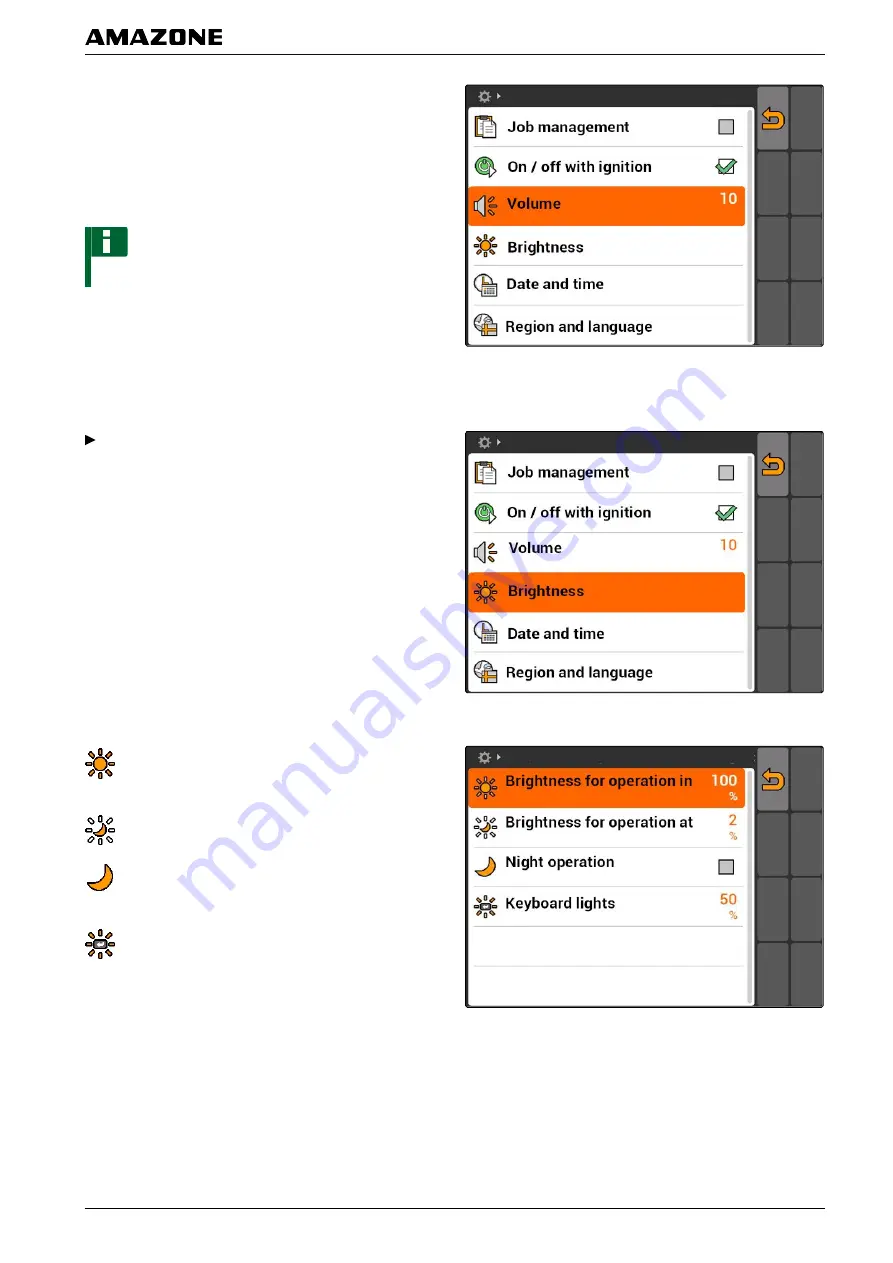

1.1.4 Setting the brightness

Select

"Setup"

>

"Settings"

>

"Basic settings"

>

"Brightness"

.

Possible settings:

: Percent value for the display brightness during the

day

: Percent value for the display brightness at night

: Sets the display brightness to the value entered

under

"Brightness for operation at night"

.

: Percent value for the brightness of the button illu-

mination on the AMATRON 3

006886

G | Configuring the setup | Entering the settings

MG5560-EN-II

| B.1 | 2016.07

25