W 3 2 S E R I E S

H I G H P R E S S U R E B R E A T H I N G A I R C O M P R E S S O R

51

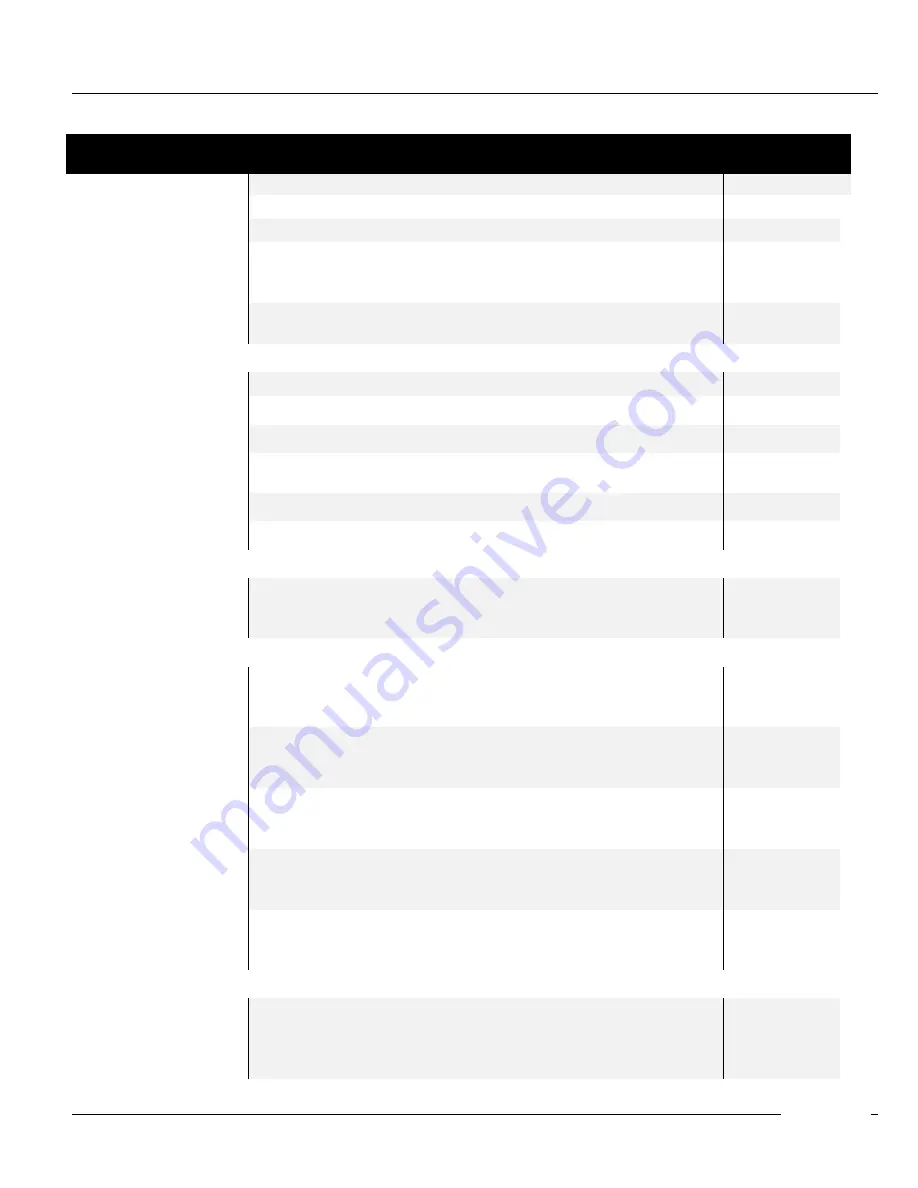

2.3.4 W32 Canopy Compressors Maintenance

–

Parts Control Table

Check

Description

Instruction

nr.

Daily

Oil level

01

Leaks

02

Pressure and pressure gauges.

-

Automatic drain valves

Note: Check daily if automatic drain valves work properly

and replace or maintain them if needed.

Drain the condensate collected inside the purifier manually

after each bottle filling or at least daily.

Weekly

Intake Filter.

03

V-Belt tension (See the V-belt replacement instruction )

04

Tightness of fastening parts.

05

Cleaning of cylinder fins, intercoolers and after cooler,

flywheel.

06

Electrical current.

07

Cable connection and wiring.

-

Every 500 hours

Safety valves

Note: Check the safety valves every 500 operating hours and

replace them if needed.

08

08-01

Every 1000 hours

Regulating valve

Note: Check the regulating valve every 1000 operating hours

and replace or maintain it if needed.

09

09-01

Check valve

Note: Check the check valve every 1000 operating hours and

replace or maintain it if needed.

10

10-01

Priorıty valve

Note: check the priority valve every 1000 operating hours

and replace or maintain it if needed.

11

11-01

V-belts

Note: Check the V-belts every 1000 operating hours and

replace them if needed.

12

Oil seal

Note: Check the oil seal every 1000 operating hours and

replace them if needed

13

Annually

Purifier

Note: Have the purifier on your unit pressure tested to the

authorized body according to the pressurized equipment test

regulations.