W 3 2 S E R I E S

H I G H P R E S S U R E B R E A T H I N G A I R C O M P R E S S O R

©ALKIN COMPRESSORS

36

1.10 Installation

1.10.1 Inspection

The compressor should be inspected and checked for the following when received:

1.

Check if any damage exists during shipping, handling, etc.

2.

Check the compressor nameplate to verify the equipment is comply with the working conditions,

3.

Check the electrical motor nameplate to verify the compliance with the available power and electrical

supply. (for electric driven models)

4.

Check the compressor if it is loaded with oil or not.

5.

Check the purifier if the cartridge is installed or not.

6.

Check if the intake filter is installed.

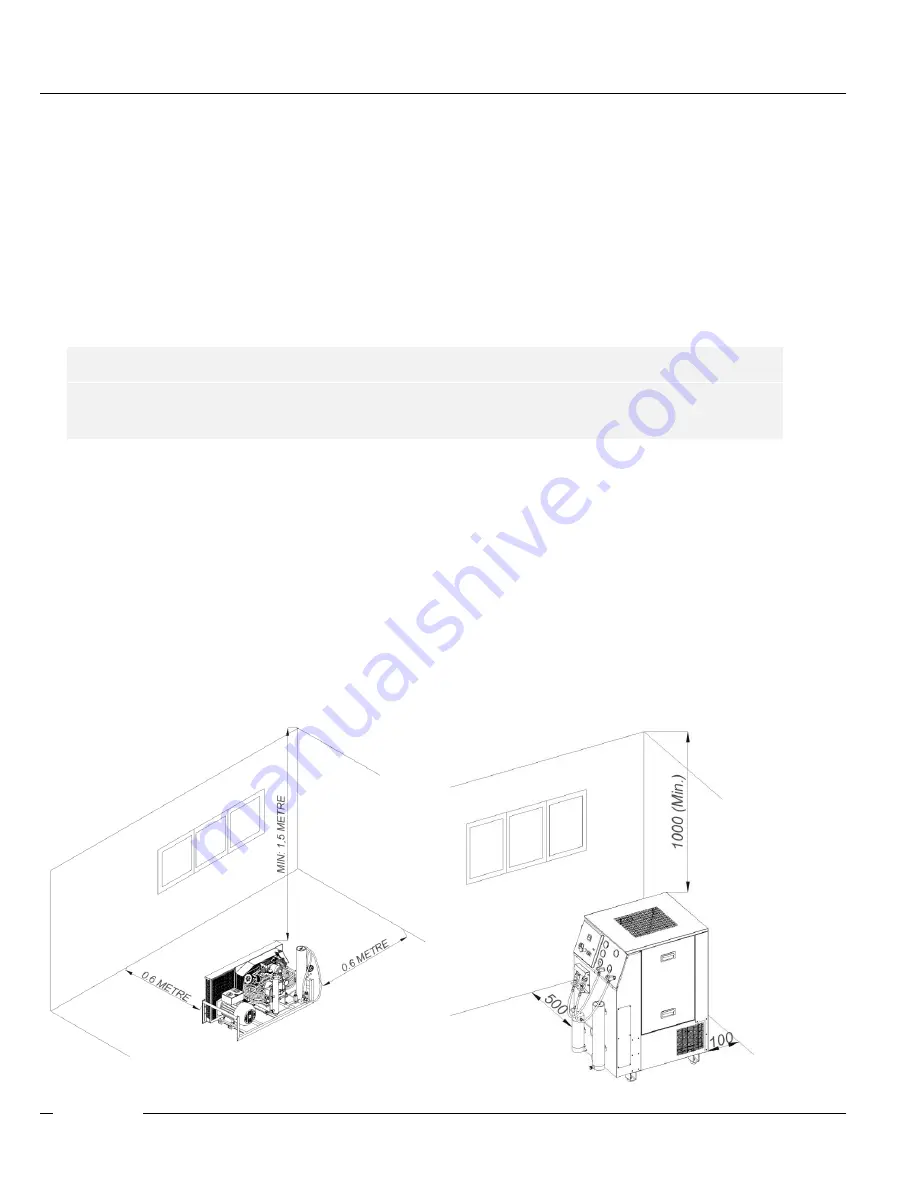

1.10.2 Location

Important

READ CAREFULLY AND FOLLOW THE INSTRUCTIONS BELOW.

The location where the compressor is installed determines to a considerable extent the overall performance and

service life of the unit.

The compressor should be located in an area that is dry and sheltered, well ventilated, not exposed to

high ambient temperatures and air borne contaminants such as dust,fumes, lint, vapor, steam, gases,

engine exhaus, etc.

Install the compressor with a minimum of advised clearance between adjacent surfaces, to insure adequate

cooling and access for service. You can find the necessary information about the clearances on the pictures

below.

Locate the compressor on a smooth surface of sufficient strength to support the static weight of the

equipment, as well as the dynamic forces resulting from its operation ( preferably on 6’’ (150 mm) thick

concrete floor)