49

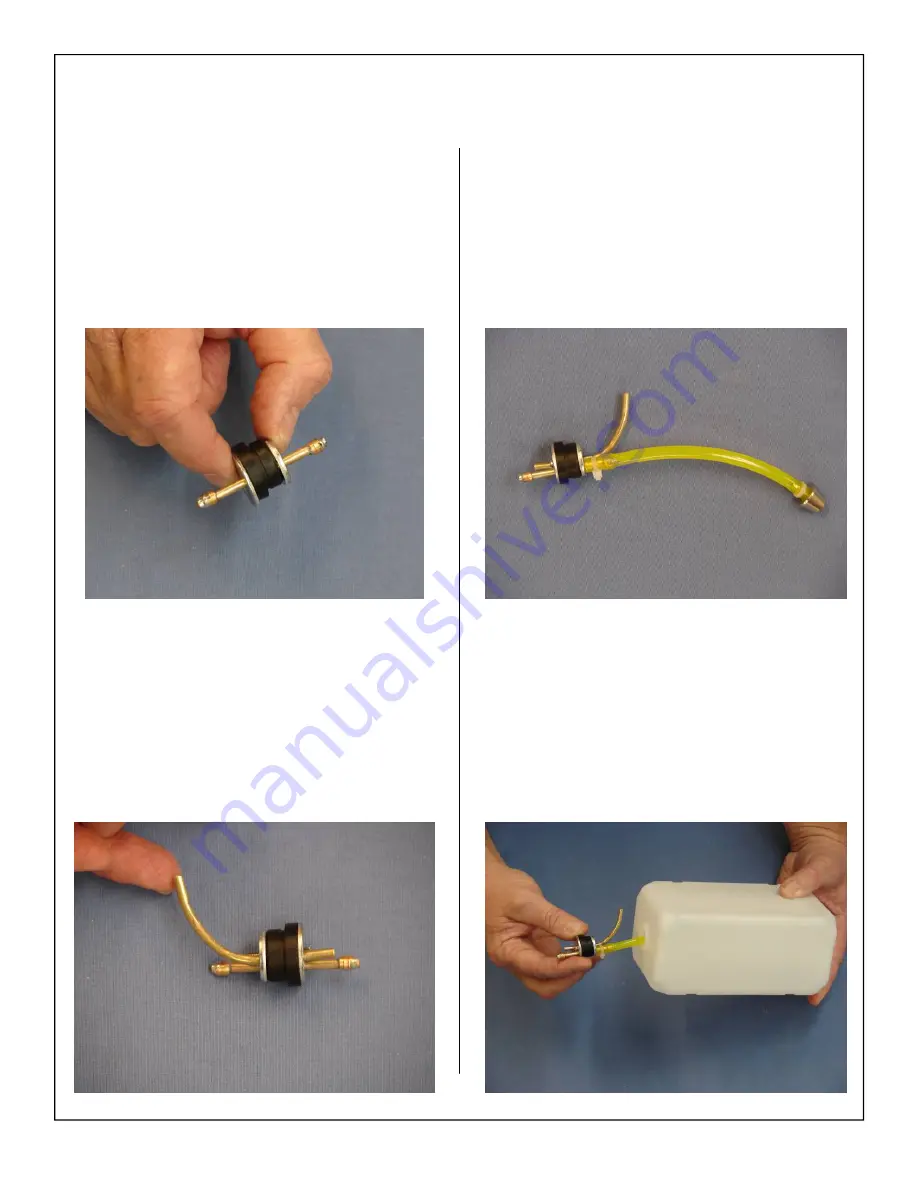

5. Final assembly of rubber fuel stopper with fuel

pick up tube shown below.

6. Install air vent tube into rubber stopper and bend

upward. Air vent tube should rest as close to the

top of fuel tank as possible. Without touching

the top of the tank.

7. Install the fuel tubing and clunk. Secure the fuel

tubing with nylon ties to the pick-up tube and

clunk.

8. Insert the rubber stopper assembly into the tank

with the vent tube at the top of the tank.